Excavator bucket tooth assembly convenient to replace

A technology of excavator bucket teeth and components, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of easy damage, inconvenient replacement, high replacement cost, etc., and achieve easy replacement, low replacement cost and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

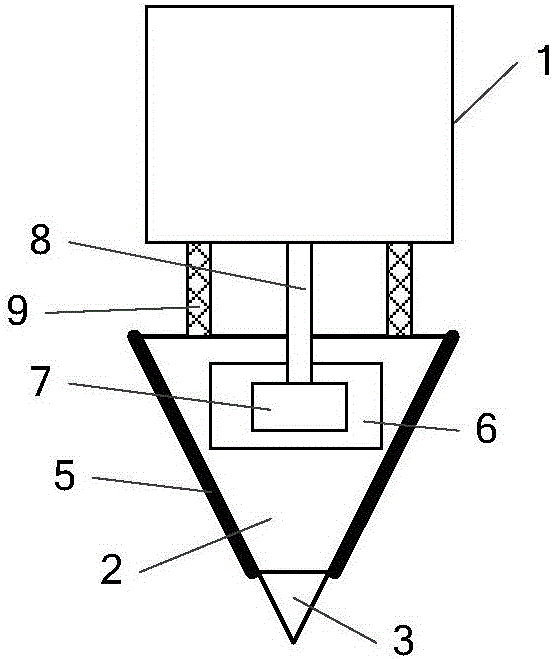

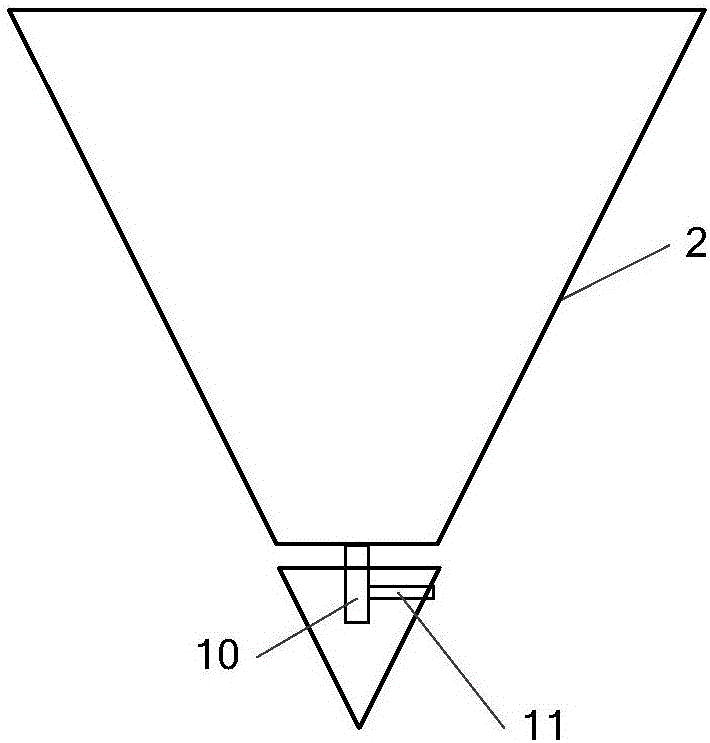

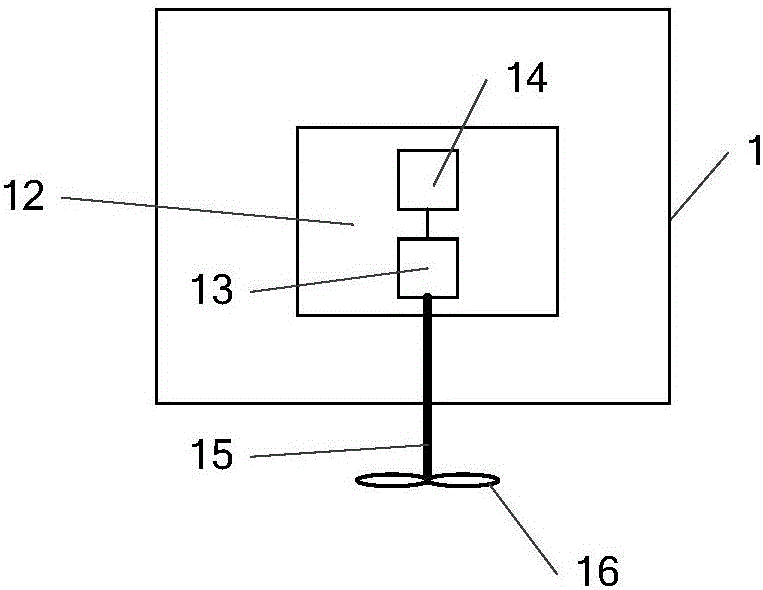

[0035] see Figure 1-Figure 5 , the present invention proposes an excavator bucket tooth assembly that is easy to replace, and the assembly includes:

[0036] A tooth seat 1 and a bucket tooth, wherein the bucket tooth includes: a tooth tip 3, a tooth body 2, and 4 tooth plates 5, a stud 10 is provided at the front end of the tooth body, and a screw hole is provided at the rear end of the tooth tip , the side of the tooth tip and the side of the stud are provided with a first fixing hole, the first fixing nail 11 is inserted into the first fixing hole to fix the threaded connection between the tooth tip and the tooth body, the front and back of the tooth body , the left side and the right side are provided with N second fixing holes, said N is a positive integer greater than or equal to 3, and the second fixing nail is inserted into the second fixing hole to fix the four tooth plates on the tooth body respectively A first cavity 6 is provided in the tooth body, a slider 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com