Construction method for assembling cone steel coal bucket of super-large type bundling polygonal coal bunker group

A construction method and technology of steel coal scuttles, applied in the field of assembling conical steel coal scuttles of super-large clustered polygonal coal bunkers, can solve the difficulty in meeting the construction requirements of large steel coal scuttles, the difficulty in eliminating the welding stress of steel coal s Unable to obtain guarantees and other issues, to achieve the effect of strong practicability and superiority, high overall structural strength, and reduced construction risk factor and construction workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

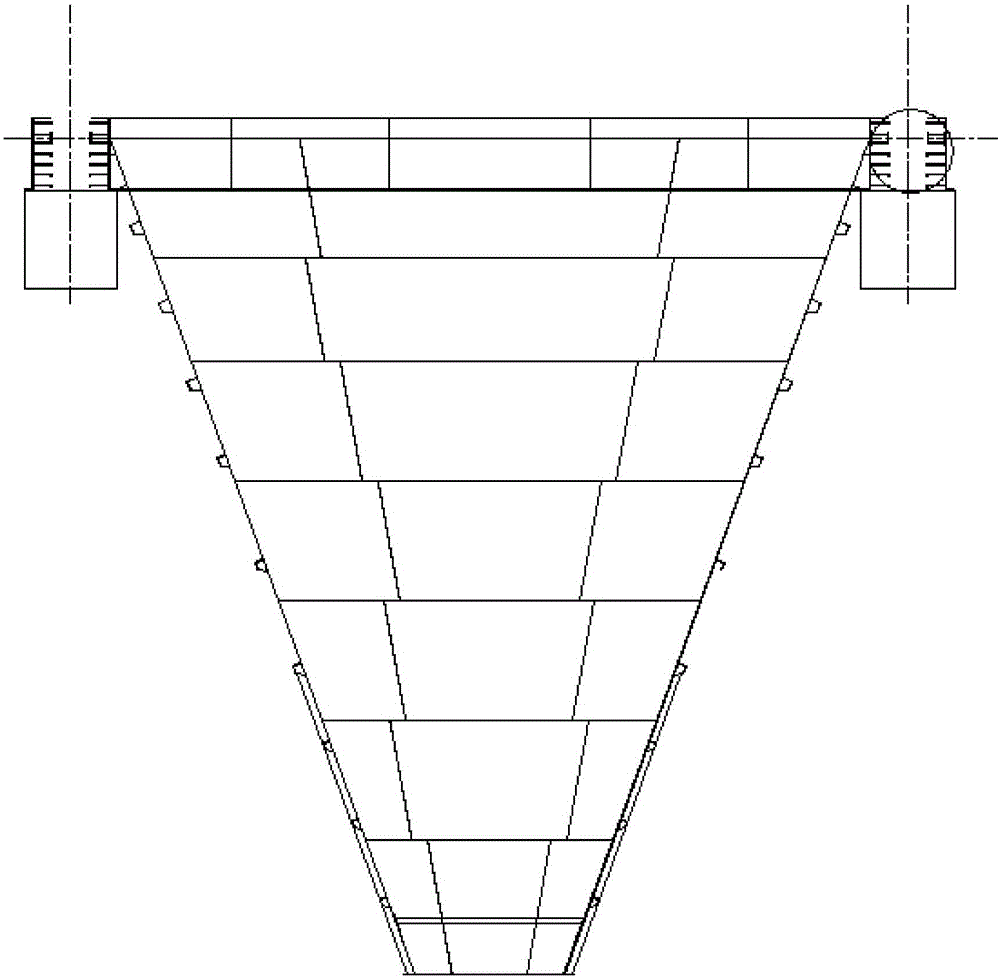

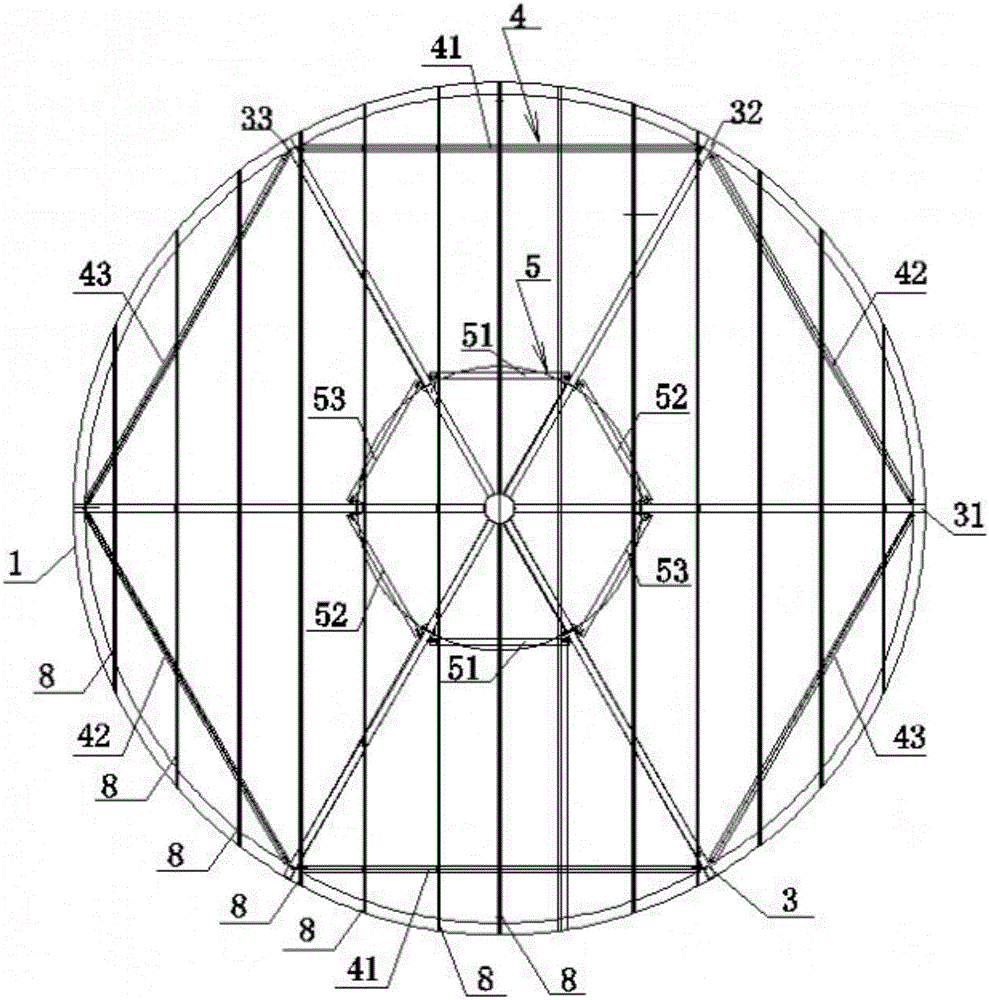

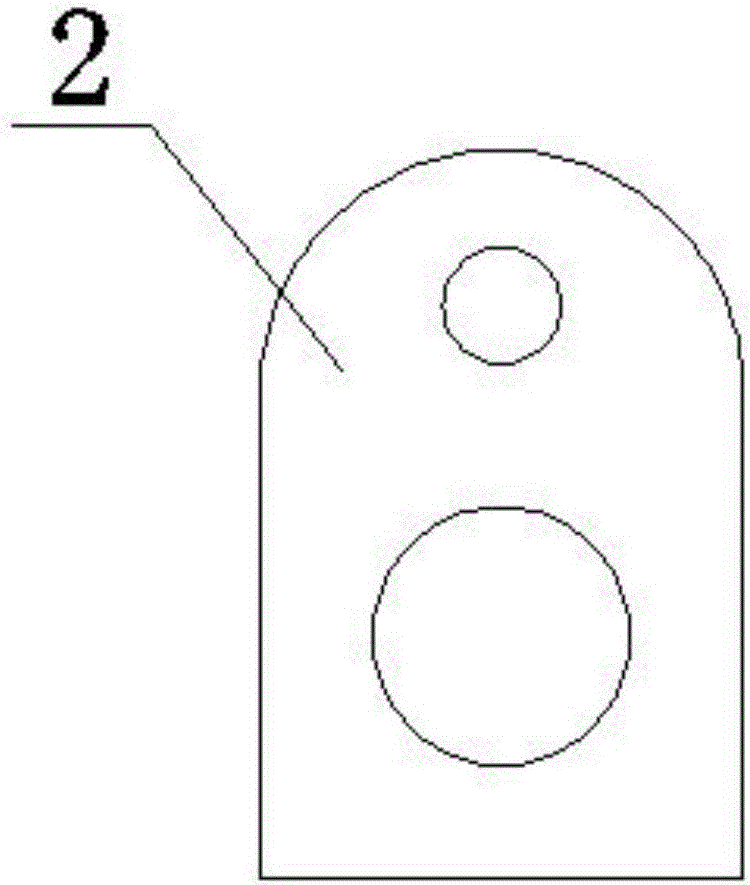

[0028] As shown in the accompanying drawings, a construction method for assembling a conical steel coal scuttle of super-large clustered polygonal coal bunkers, which utilizes a free lifting platform 11 and an electric hoist for assembling construction. Wherein, the free lifting platform 11 includes a circular truss structure 1, a steel plate (not shown) laid on the truss structure 1 and a plurality of lifting lugs 2 connected to the edge of the truss structure, the truss structure 1 includes a plurality of steel pipe structures 3 arranged through the center of the truss structure. In the embodiment of the present invention, three steel pipe structures 3 are arranged, and the three steel pipe structures 3 are evenly arranged, which are respectively steel pipe structure A31, steel pipe structure B32 and steel pipe structure C33, The three steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com