Electric power maintenance ladder

A technology of electric power maintenance and vertical poles, which is applied in the direction of ladders, buildings, building structures, etc., can solve problems such as maintenance ladder slipping, physical hazards of staff, hidden safety hazards of maintenance personnel, etc., to ensure stability and firmness, and facilitate climbing operations. The effect of preventing the danger of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

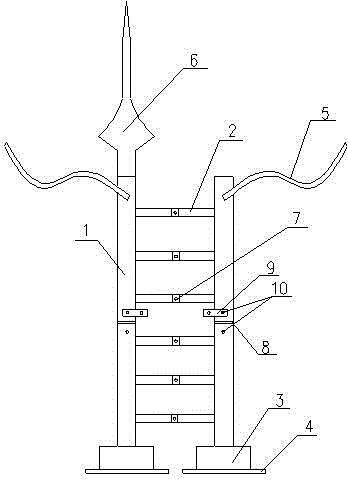

[0022] like figure 1 As shown, an electric maintenance ladder includes a support vertical bar 1 and a cross bar 2. The support vertical bar 1 and the cross bar 2 are all coated with a luminous coating, which emits light at night to remind the vehicle that someone is nearby. The two support vertical bars 1 are connected by several cross bars 2, the two support vertical bars 1 are fixed on the base 3, and the bottom of the base 3 is provided with a rubber pad 4, the area of the rubber pad 4 is larger than the area of the base 3, increasing the It reduces friction and ensures the stability and firmness of the maintenance ladder.

[0023] A strap 5 is fixed on the tops of the two supporting vertical bars 1. When in use, the two straps can be bound together around the power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com