Jet type loose-wing reaming drilling tool and manufacturing method and using method thereof

A manufacturing method and a technology of reaming drills, which are applied in the direction of drilling equipment and methods, drill bits, drilling equipment, etc., can solve the problems of low reaming efficiency and high cost of using drill bits, and achieve good reaming quality, lower drilling tool costs, The effect of a simple connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

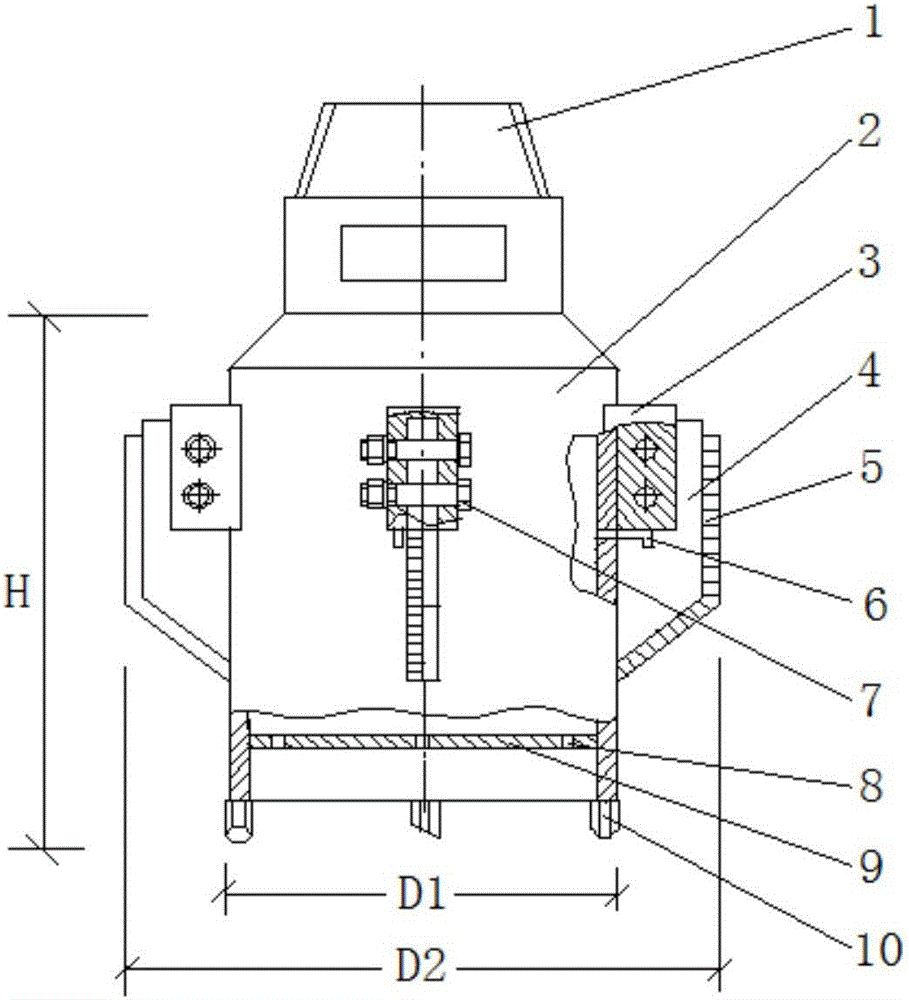

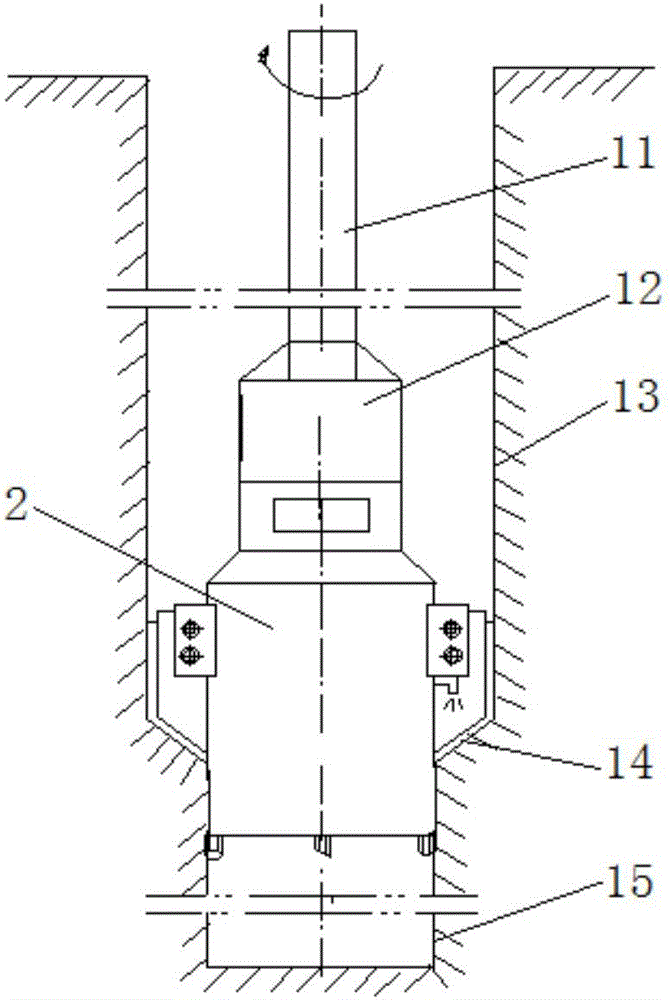

[0055] Design final drilling diameter of an engineering survey hole The drilled strata are mainly Quaternary and weathered sedimentary rocks (mudstone, shale, sandstone, etc.), and the drilling depth is 50m. Using 2 times of hole forming, pre-drilling pilot hole 15, pilot hole 15 drilling outer diameter Then through 1 reaming to reach the designed drilling diameter The reaming drilling adopts the above-mentioned jet-type movable wing reaming drilling tool. The structural composition and manufacturing method of the drilling tool are as follows:

[0056] (a) The outer diameter of the production is A drill bit body 2 with a wall thickness of 10 mm and an effective height H of 600 mm, and a male joint 1 for connecting a drill string 11 is arranged on the upper end of the drill bit body 2 for connecting drill rods. The outer diameter of the drill string 11 is A pilot cutting tool 10 is inlaid on the bottom surface of the drill bit body 2, which is used for pilot hole sweepi...

Embodiment 2

[0067] Design final drilling diameter of a water supply pipe well The drilled strata are mainly Quaternary, Tertiary and sedimentary rocks (mudstone, shale, slate, sandstone, etc.). The upper part of the rock is weathered, the middle part is relatively complete, and the lower part is cracked sandstone (water-containing fractured zone). The drilling depth is 300m. Using 2 times of hole forming, pre-drilling pilot hole 15, pilot hole 15 drilling outer diameter Then through 1 reaming to reach the designed drilling diameter The reaming drilling adopts the above-mentioned jet-type movable wing reaming drilling tool. The structural composition and manufacturing method of the drilling tool are as follows:

[0068] (a) The outer diameter of the production is A drill bit body 2 with a wall thickness of 16 mm and an effective height H of 800 mm, and a male joint 1 for connecting a drill string 11 is arranged on the upper end of the drill bit body 2 for connecting drill rods. The ...

Embodiment 3

[0079] Design final drilling diameter of a water supply pipe well The drilled formations are mainly Quaternary, Tertiary and sedimentary rocks (mudstone, slate, sandstone, etc.), the upper part of the rock is weathered, and the lower part is cracked sandstone (water-bearing fractured zone). The drilling depth is 200m. Using 2 times of hole forming, pre-drilling pilot hole 15, the outer diameter of the pilot hole 15 Then through 1 reaming to reach the designed drilling diameter The reaming drilling adopts the above-mentioned jet-type movable wing reaming drilling tool. The structural composition and manufacturing method of the drilling tool are as follows:

[0080] (a) The outer diameter of the production is A drill bit body 2 with a wall thickness of 12 mm and an effective height H of 700 mm, and a male joint 1 for connecting a drill string 11 is arranged on the upper end of the drill bit body 2 for connecting drill rods. The outer diameter of the drill string 11 is A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com