High pressure shielding cycloid pump

A cycloid pump, high pressure technology, applied in the pump, rotary piston/swing piston pump combination, pump components and other directions, can solve the problems of high lift, small flow of booster pump, performance deviation of booster pump, etc. Simple and compact structure, improved reliability, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

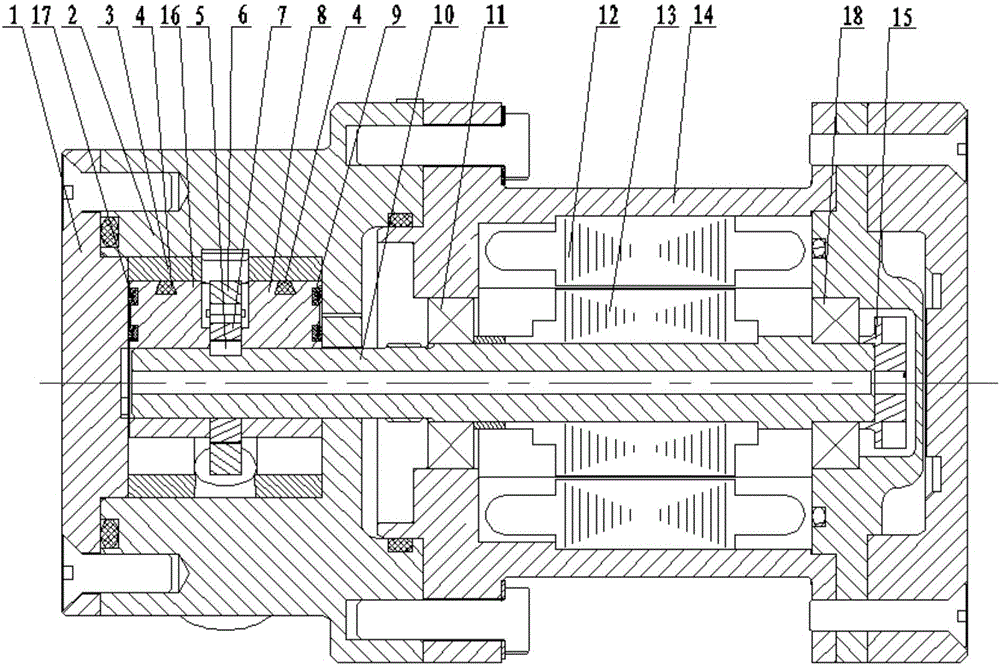

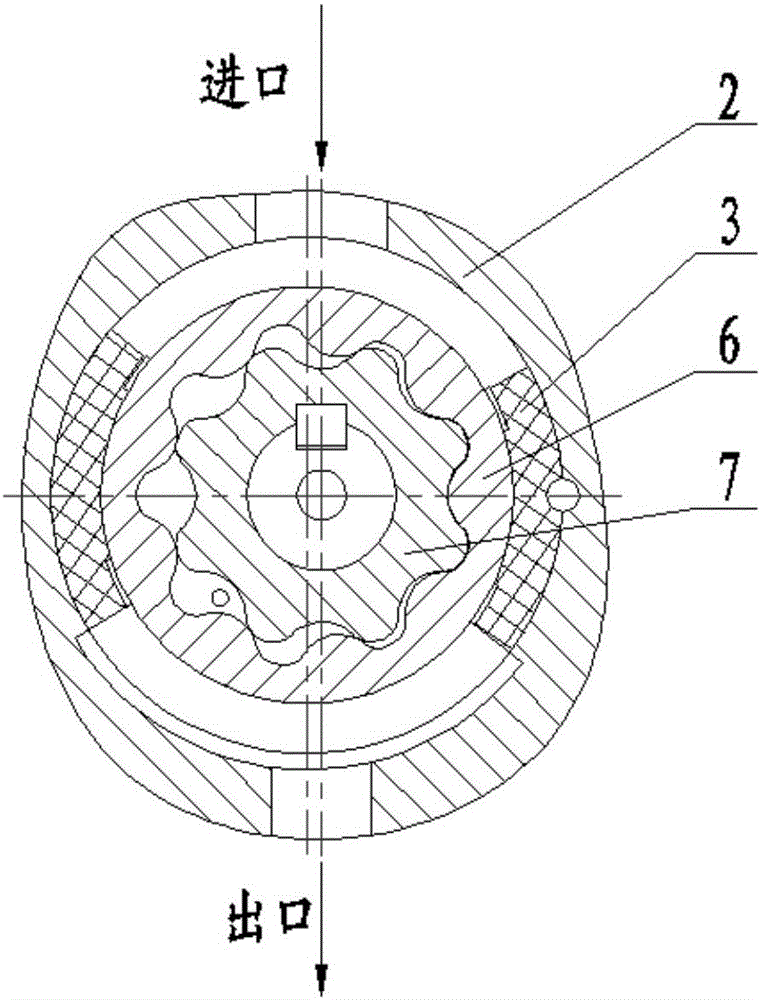

[0023] like figure 1 The high-voltage shielded cycloidal pump shown includes an end cover 1, a housing 2, an epicycloidal rotor 6, an intracycloidal rotor 7, a shaft 10, a left bearing 11, a right bearing 18, a motor housing 14, a motor stator 12, The motor rotor 13 and the position sensor 15; the left bearing 11 and the right bearing 18 are arranged on both sides of the motor rotor 13 to support the rotation of the shaft system. The hypocycloidal rotor 7 is installed on the cantilever end of the shaft 10 through the key 5, and the rotation of the motor rotor 13 drives the inner swing The linear rotor 7 rotates, and the epicycloid rotor 6 and the hypocycloid rotor 7 rotate in the same direction to form a volume alternately changing cavity to realize the process of sucking and pressurizing the liquid medium. The hypocycloid rotor 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com