Dual-power input pure electric transmission

A pure electric and transmission technology, applied in vehicle gearboxes, multi-gear ratio transmissions, transmission elements, etc., can solve problems such as unfavorable overall layout of pure electric vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

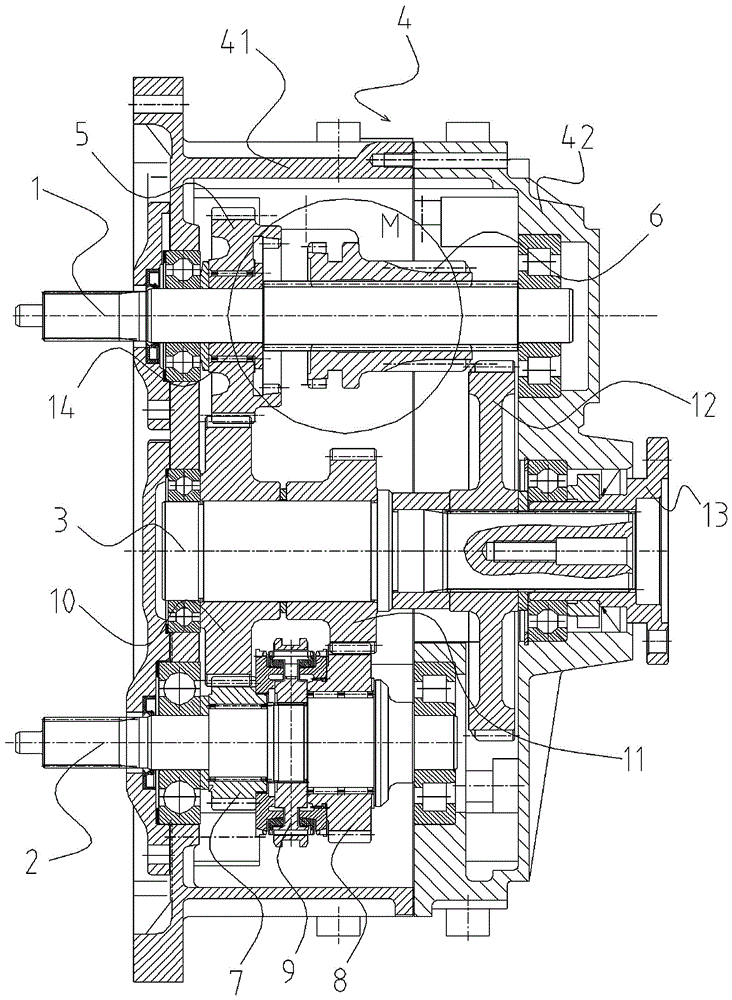

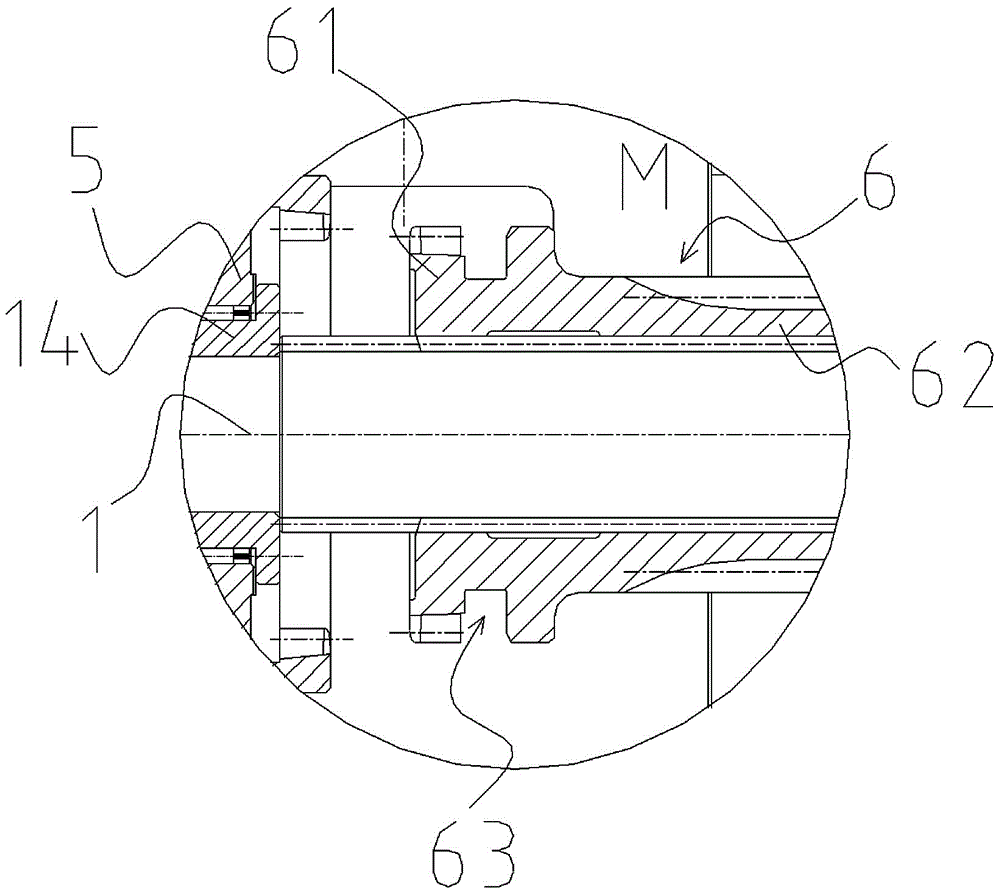

[0022] see figure 1 and figure 2 , is a specific embodiment of a dual power input pure electric transmission. The dual power input pure electric transmission includes a transmission case 4. In this embodiment, the transmission case 4 is composed of a left case 41 and a right case 42 connected by a plurality of bolts to form a whole. The transmission housing 4 is provided with a first input shaft 1, a second input shaft 2, and an output shaft 3, and the two ends of the first input shaft 1, the second input shaft 2, and the output shaft 3 are respectively supported on the left side by bearings. On the housing 41 and the right housing 42, wherein, one end of the first input shaft 1 and the second input shaft 2 protrude from the left housing 41, and one end of the output shaft 3 protrudes from the right housing 42, and an output The flange 13 is fixedly connected in the circumferential direction. The first input shaft 1 is fitted with a third-speed drive gear 5 through a beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com