A double-wedge movable gate group driven by mechanical and internal pressure

A technology of internal pressure and gate, which is applied in the direction of mechanical equipment, sliding valves, engine components, etc., can solve the problems of reducing the friction between the gate and the valve seat, short service life, easy fracture of the valve stem, etc., and achieve valve stem fracture Reduced risk, improved stability and safety, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

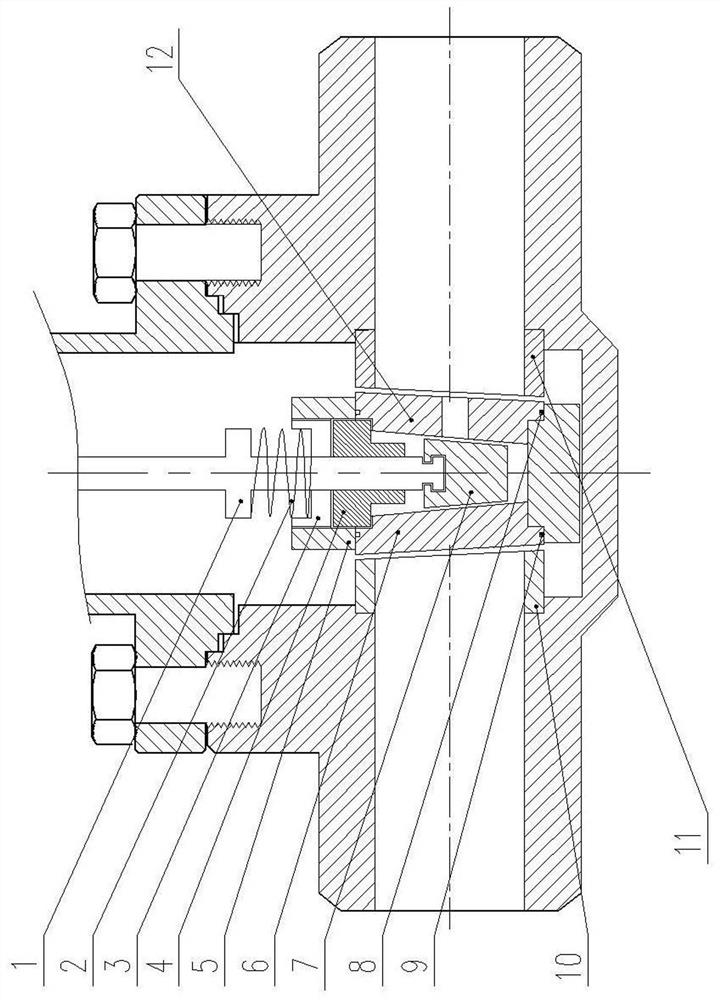

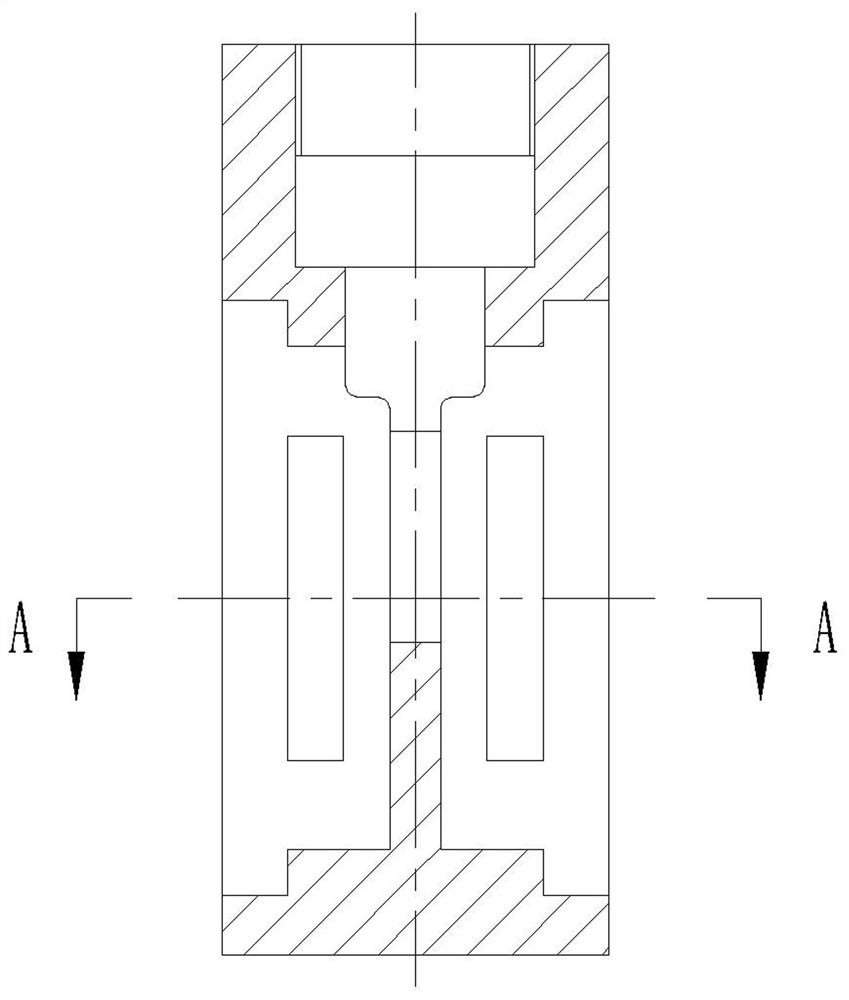

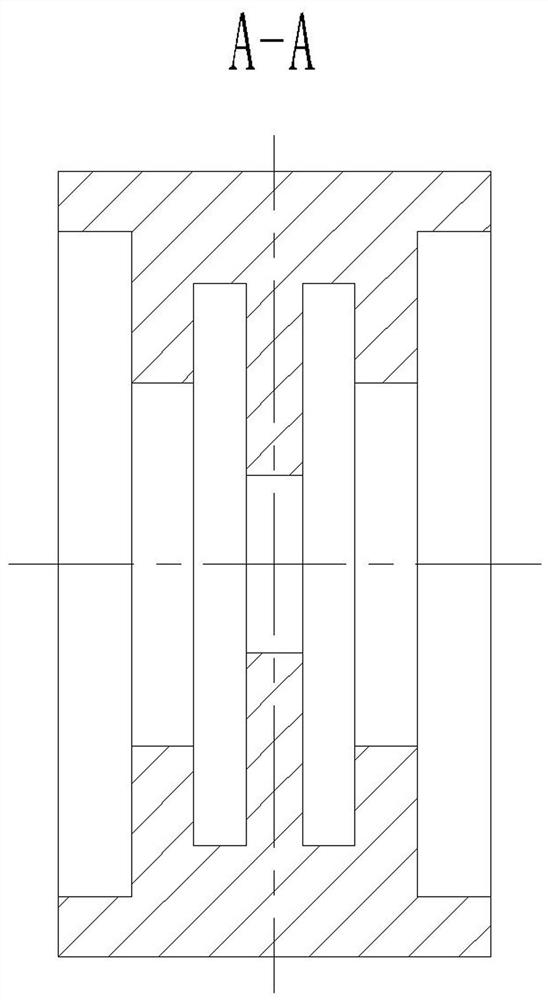

[0035] A double-wedge movable gate group driven by mechanical and internal pressure includes: valve stem 1, spring 2, spring seat 3, positioning sleeve 4, gate body 5, first movable gate 6, pilot gate 7, The first ram ring 8, the second ram ring 9, the valve seat 10 before the valve, the valve seat 11 after the valve and the second movable ram 12; it is characterized in that:

[0036] The pilot gate 7 is inserted from the upper hole of the gate body 5;

[0037] The lower end of the positioning sleeve 4 is inserted from the upper port of the gate body 5, and is fixedly connected between the positioning sleeve 4 and the gate body 5; the lower end of the spring seat 3 is inserted from the upper port of the gate body 5, and the lower end of the spring seat 3 touch Hold the upper end of the positioning sleeve 4, and the spring seat 3 is fixedly connected with the gate body 5;

[0038] The lower end of the spring 2 is against the second surface 16 of the spring seat 3;

[0039] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com