A kind of antifreeze double-layer composite pipe

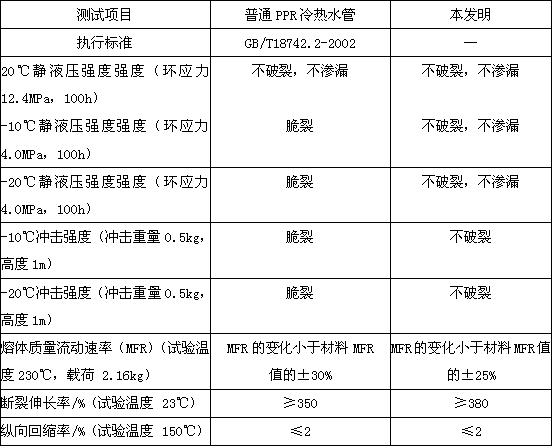

A double-layer composite, outer-layer technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of easy cracking, low temperature brittleness, etc., to increase pressure resistance, good toughness and impact resistance, Solve the effect of easy freeze cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention proposes a kind of frost-resistant double-layer composite pipe, which consists of a dense inner layer and an outer layer. The thickness ratio of the dense inner layer is 15-85%, and the thickness ratio of the outer layer is 85-15%. The dense inner matrix is high-density polyethylene, and the outer matrix includes the following components and the mass ratio of each component is: 100 parts of random copolymerized polypropylene, 2 to 8 parts of nucleating agent, and 1 to 5 parts of compatibilizer . The preparation method of the antifreeze double-layer composite pipe is as follows: pour random copolymerized polypropylene, high-density polyethylene, nucleating agent and compatibilizer into the mixer according to the formula ratio, mix evenly, and use a twin-screw granulator to make In the co-extruder, the host high-density polyethylene is extruded through a single-screw extruder to form a dense inner layer, and then the granulated material is extruded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com