Scale removal pipeline and using method thereof

A technology for pipes and hoses, which is applied in the field of industrial wet-process phosphoric acid, crude oil transportation or other fouling-prone material transportation systems. It can solve the problems of shutting down for cleaning, high cost of pipe manufacturing, and unsatisfactory problems, so as to avoid leakage pollution and use Effect of long life and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

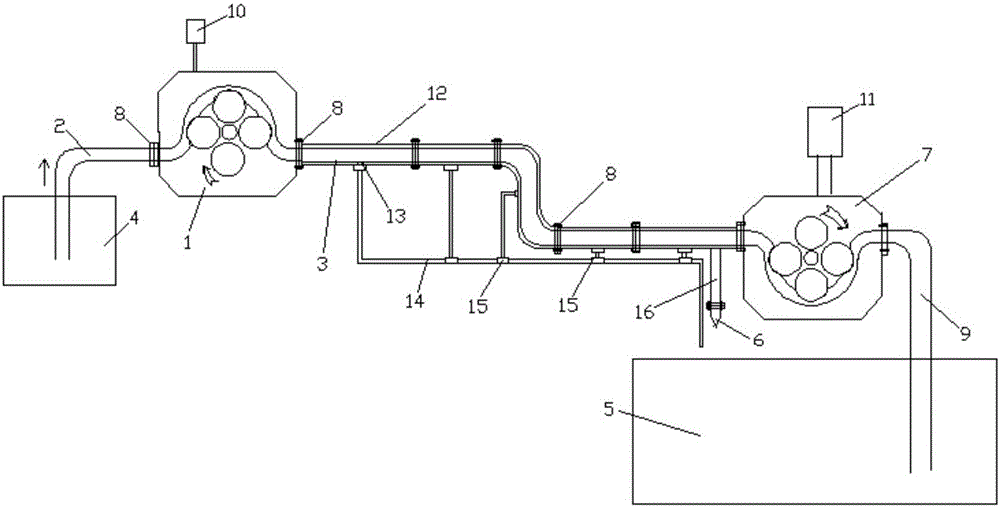

[0023] Wet-process phosphoric acid semi-aqueous phosphoric acid transport descaling pipeline with a diameter of 80mm, refer to figure 1 .

[0024] Including the first peristaltic pump 1, feeding pipe 2, feeding hose 3, rubber check valve 6, second peristaltic pump 7, flange 8, discharge pipe 9, first time relay 10, second time relay 11 And hard pipe 12, all are fixed by flange 8 between the connected pipe and pipe.

[0025] The pipe hose 3 is made of aramid fiber braided reinforced EPDM pipe, with a flange 8 at the end of the pipe, and the inner diameter of the pipe hose 3 is 80 mm; Connected hard pipe 12, hard pipe 12 adopts polypropylene injection molding pipe, with flange 8 at both ends of the pipe, every 200mm on the hard pipe 12 is a vent hole 13 with a diameter of 2mm, and the outer diameter of the delivery hose 3 is the same as The inner diameter of the hard pipe 12 is matched, and the air holes 13 on the hard pipe 12 are sealed and communicated with one end of the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com