Rotor type oil pump assembly capable of automatically regulating oil pressure

An oil pressure and oil pump technology, which is used in engine lubrication, rotary piston type/swing piston type pump parts, engine components, etc. problem, to achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structural principle of the present invention will be further described by specific embodiments below.

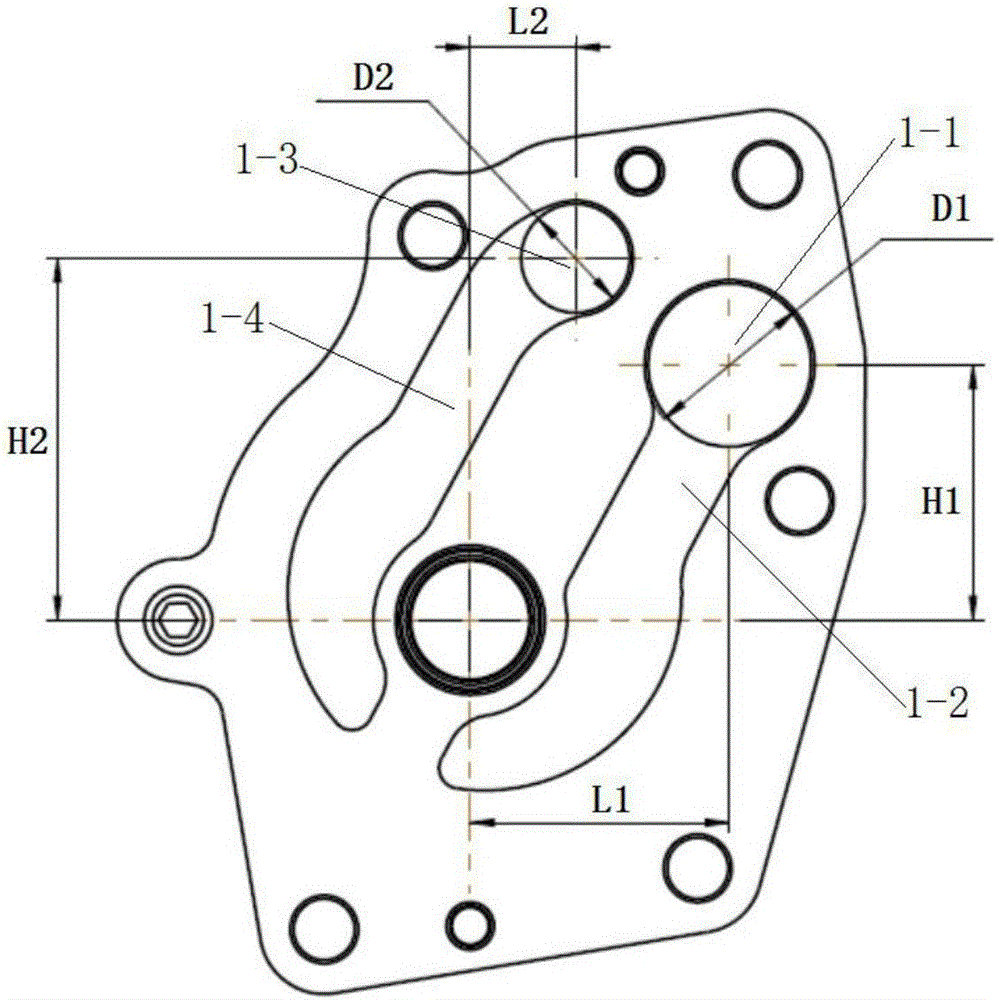

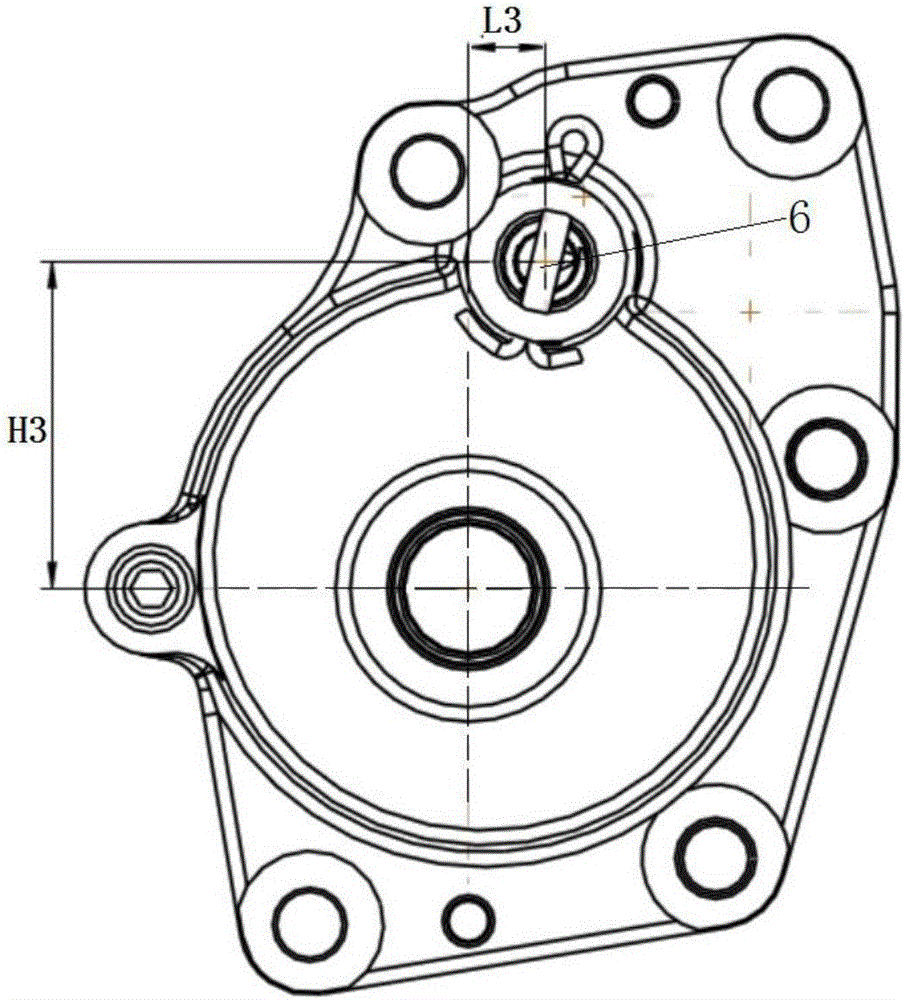

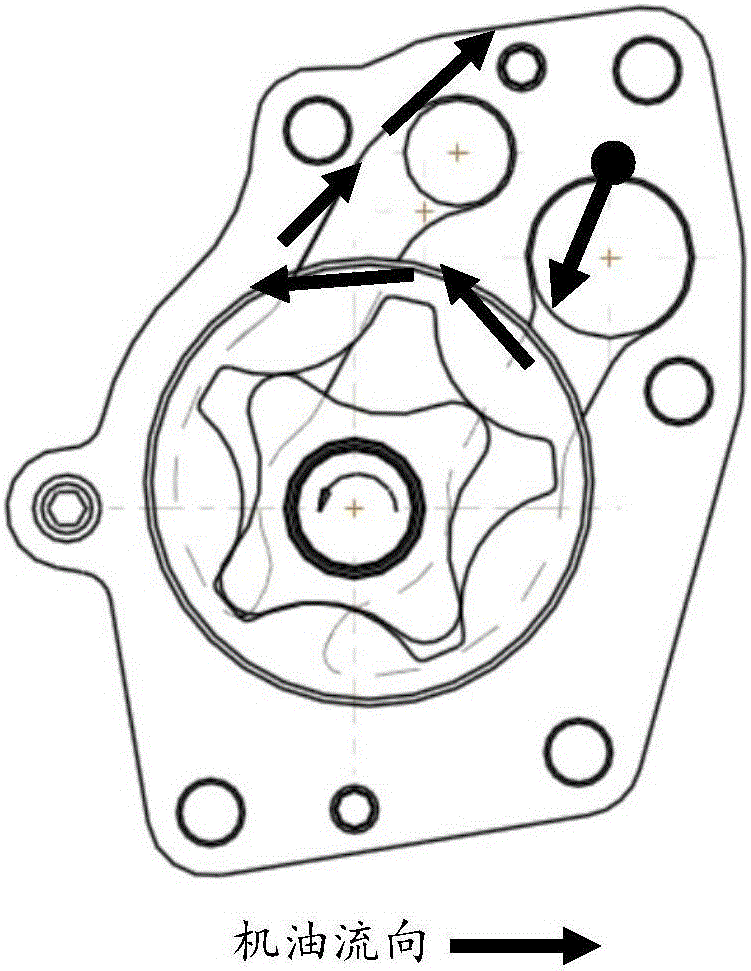

[0014] The rotor type oil pump assembly that can automatically adjust the oil pressure has the following structure: an oil inlet 1-1 and an oil inlet 1-2 are provided on the side of the oil pump cover 1 surrounding the drive shaft hole; The other side of the shaft hole is provided with an oil outlet 1-3 and an oil passage 1-4. An inner rotor 4 is arranged on the oil pump housing 2 around the drive shaft. The outer rotor 3 is placed outside the outer rotor. When the inner rotor rotates, the outer rotor is driven to rotate, and a working cavity is formed between the teeth of the inner and outer rotors. The inner rotor and the driving gear 7 are fixed on the transmission shaft 5 by interference fit, and the pressure regulating valve 6 is arranged at one end of the oil pump housing.

[0015] The pressure regulating valve is successively provided with a pressure regulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com