Cooking fume exhaust method for energy-saving stove

The technology of cooking fume and fume hood is applied in the field of oil fume extraction of energy-saving stoves, which can solve the problems of affecting the health of on-site personnel, poor fume extraction effect, and high exhaust fan power, etc., and achieves outstanding energy saving effect, remarkable effect, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

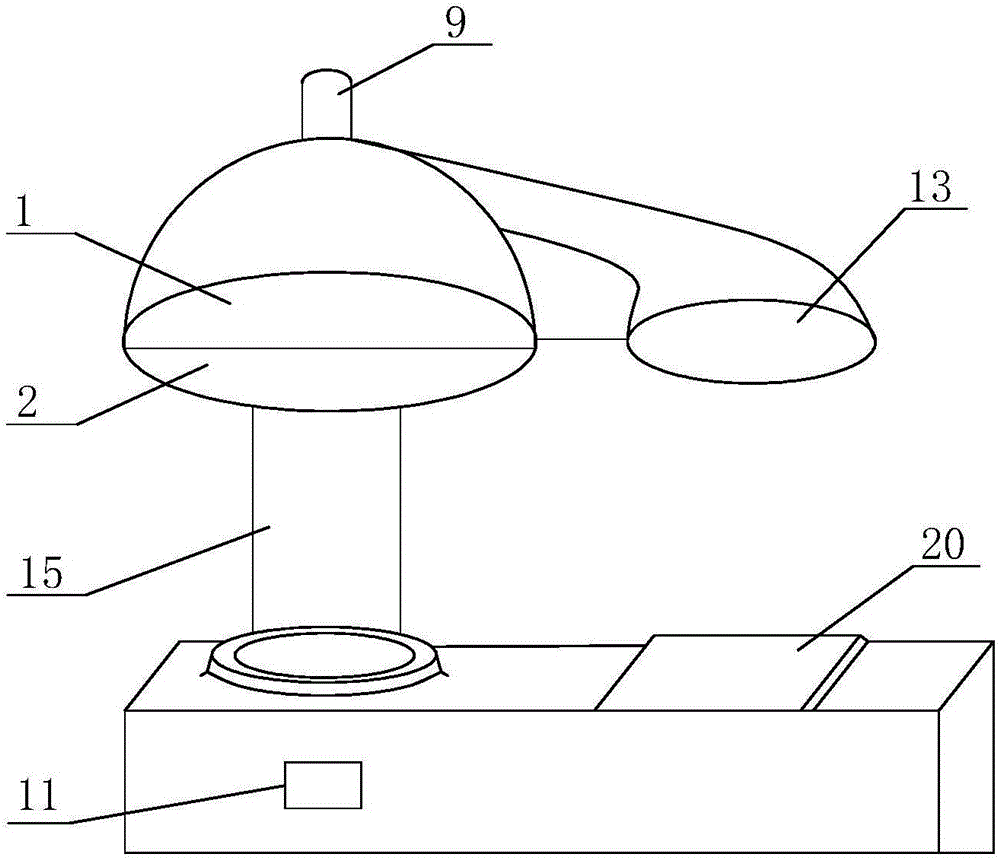

[0029] The first embodiment: the burner fume hood 2 and the overturning fume hood 1 are provided with independent exhaust passages and exhaust ports, and exhaust fans are respectively arranged behind the exhaust ports.

[0030] Set a burner position sensor for the burner position of the stove, and set a pot position sensor for the pot position. When the burner position sensor detects that the hot pot is at the burner position, turn on the exhaust fan of the burner fume hood 2; in the pot position When the sensor detects that the high-temperature pot is in the inverted position, the exhaust fan of the inverted fume hood 1 is turned on. The two exhaust fans can operate independently. When the burner position sensor does not detect that the high temperature cookware is in the burner position, turn off the exhaust fan of the burner fume hood 2; when the burner position sensor does not detect the high temperature cookware in the fire position When in position, turn off the exhaust fan...

Embodiment 2

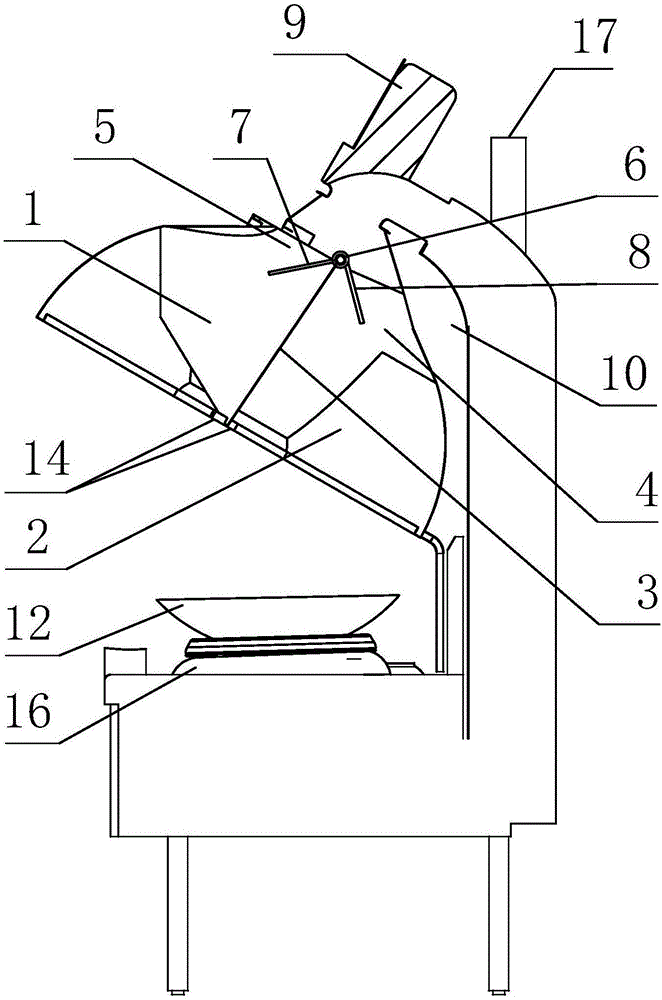

[0032] Embodiment two: such as figure 1 or figure 2 , The fire vent fume hood 2 and the pan pot fume hood 1 are provided with a common exhaust fan, share the exhaust channel, and set independent exhaust fans at other positions.

[0033] Such as figure 1 , 2 , The burner fume hood 2 and the overturned fume hood 1 are arranged in the same fume hood, separated by a partition 3, and the angle between the partition 3 and the axis of the exhaust fan is not greater than 10°, Since the hood 1 is arranged on the side of the operator of the burner hood 2, the plane of the partition basically faces the operator, and is raised facing the operator. A common exhaust port is provided behind the partition 3, and a common exhaust fan is provided behind the exhaust port.

[0034] The pot position sensor 14 transmits a signal to the induction actuator 11 when the high-temperature pot is at the pot-up position, and the induction actuator 11 turns on the exhaust fan and the pot-up exhaust port 5, and ...

Embodiment 3

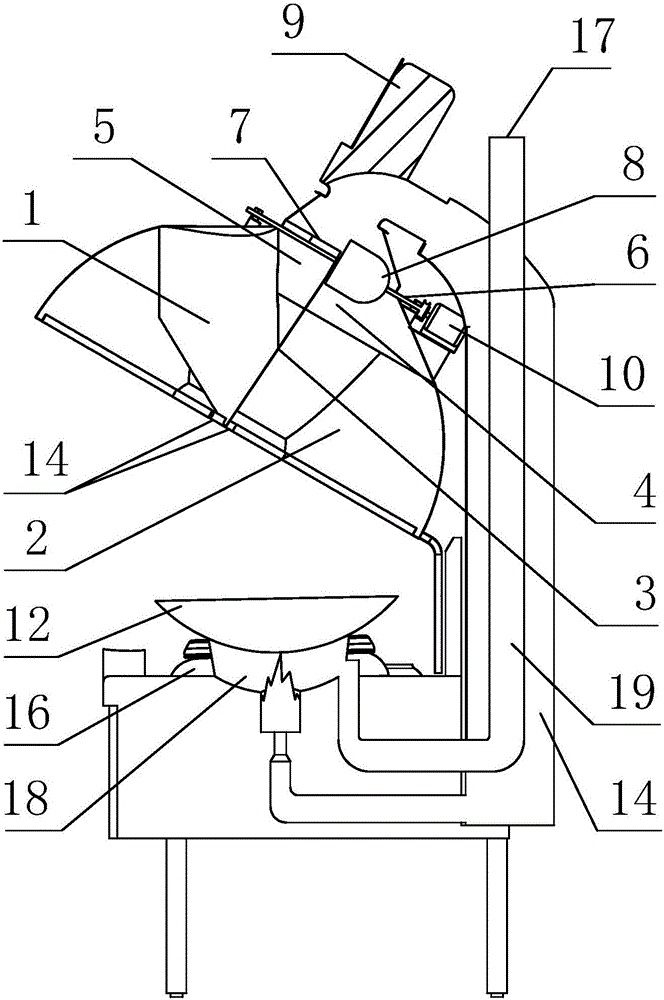

[0039] Embodiment three: such as figure 1 or figure 2 , The fire vent fume hood 2 and the pan pot fume hood 1 are equipped with a common exhaust fan, and share the exhaust channel, and the exhaust channels in other positions also share the same exhaust fan.

[0040] The burner fume hood 2 and the overturned fume hood 1 are arranged in the same fume hood, separated by a partition 3, and the angle between the partition 3 and the axis of the exhaust fan is not more than 10°, because The fume hood 1 is arranged on the side of the operator of the burner fume hood 2, and the plane of the baffle basically faces the operator, and is raised facing the operator. A common exhaust port is provided behind the partition 3, and a common exhaust fan is provided behind the exhaust port.

[0041] Valves are set in the pan-pan suction port 5 and the flame-vent suction port 4 between the partition plate and the exhaust fan. When the stove is in use, the exhaust fan keeps running. By changing the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com