Villous fin fiber composite groove type special-shaped heat pipe and manufacturing method thereof

A technology of fiber composite and velvet fins, which is applied in the field of velvet fin fiber composite grooved special-shaped heat pipes and its production, can solve the problem of restricting the application of grooved heat pipes, the difficulty of satisfying heat dissipation requirements of grooved heat pipes, and the destruction of micro grooves Structure and other issues, to achieve the effect of reducing resistance, making up for low limit power, and enhancing heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

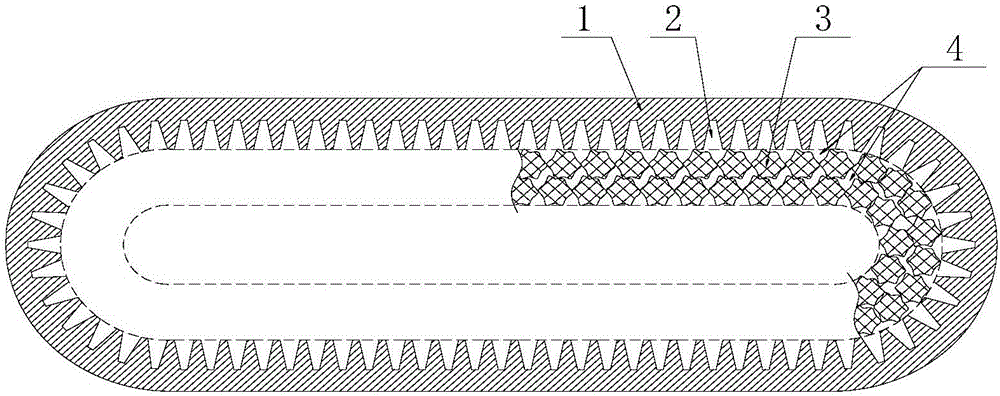

[0028] Such as figure 1 As shown, a special-shaped heat pipe with velvet fin fiber composite grooves includes a heat pipe body 1 with a special-shaped cross section, grooves 2 are arranged on the inner wall of the heat pipe body, and protrusions are formed between adjacent grooves 2. The inner wall of the heat pipe main body 1 is laid with a velvet-shaped fin fiber layer 3 . The special-shaped heat pipe refers to a heat pipe with a cross section that is not circular, and can be specifically oval, rectangular, or oblate. It can be processed into other regular or irregular shapes as required.

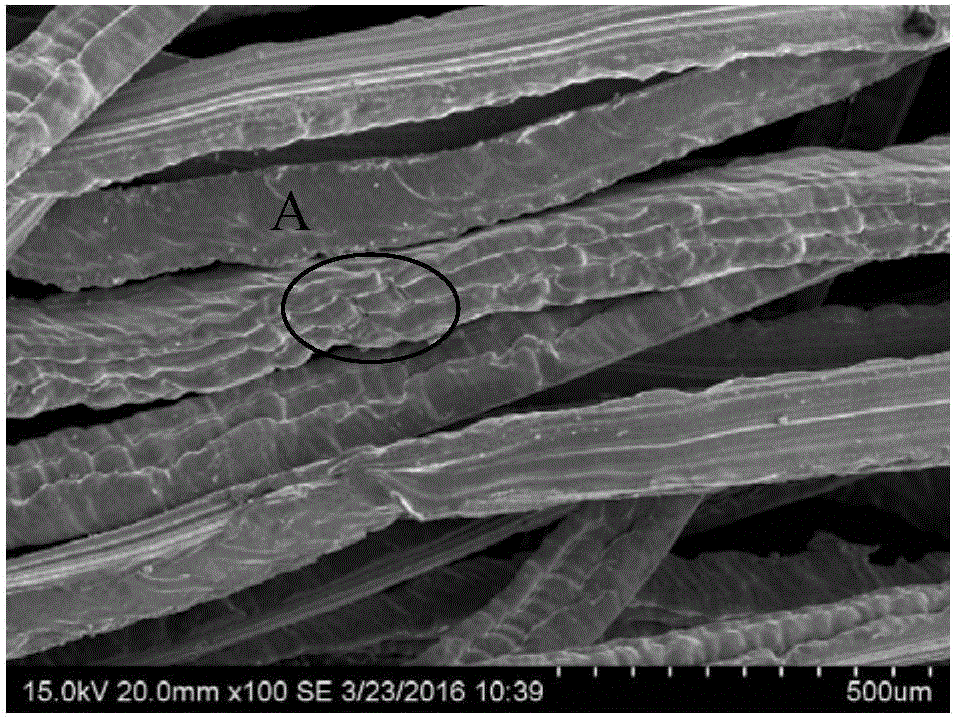

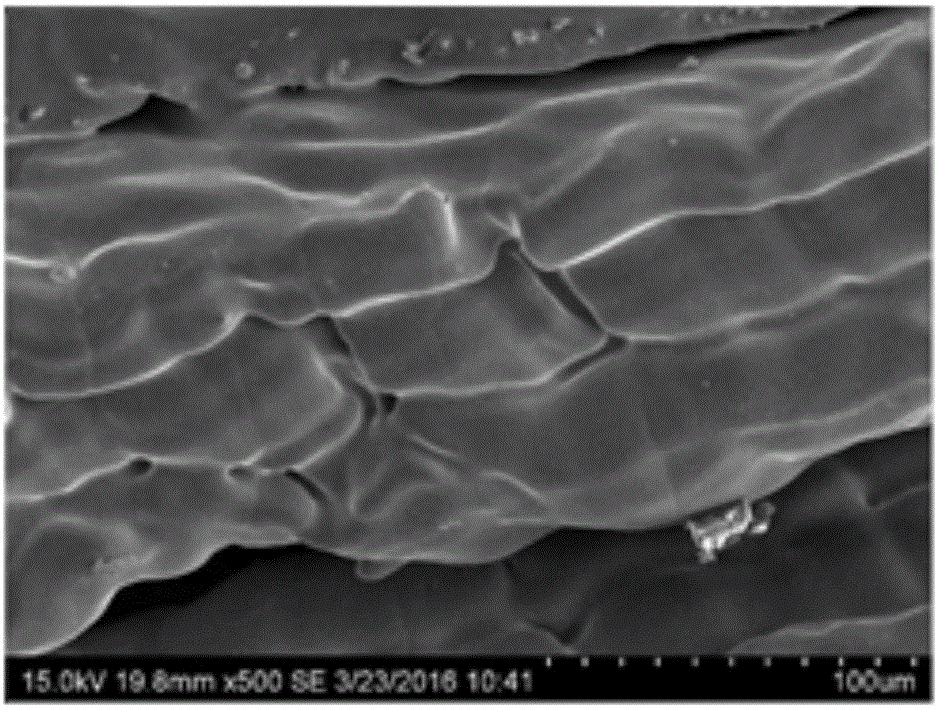

[0029] The velvet wing fiber is a filamentous body with a rough surface made by cutting with a special multi-tooth cutter. Due to the extrusion and friction between the rake face of the cutter and the forming surface, irregular protrusions or defects are formed on the fiber surface. , and a large number of tiny velvet-like fin structures, the filaments are slender and continuous with hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com