Anti-washing mechanism for heat exchanger

A heat exchanger and anti-shock technology, which is applied to the heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problem that the anti-shock plate is not conducive to cleaning and maintenance, inconvenient for repair and replacement, and increases the cost of heat exchanger layout. Space and other problems, to reduce the direct force, prevent falling off, reduce the effect of impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

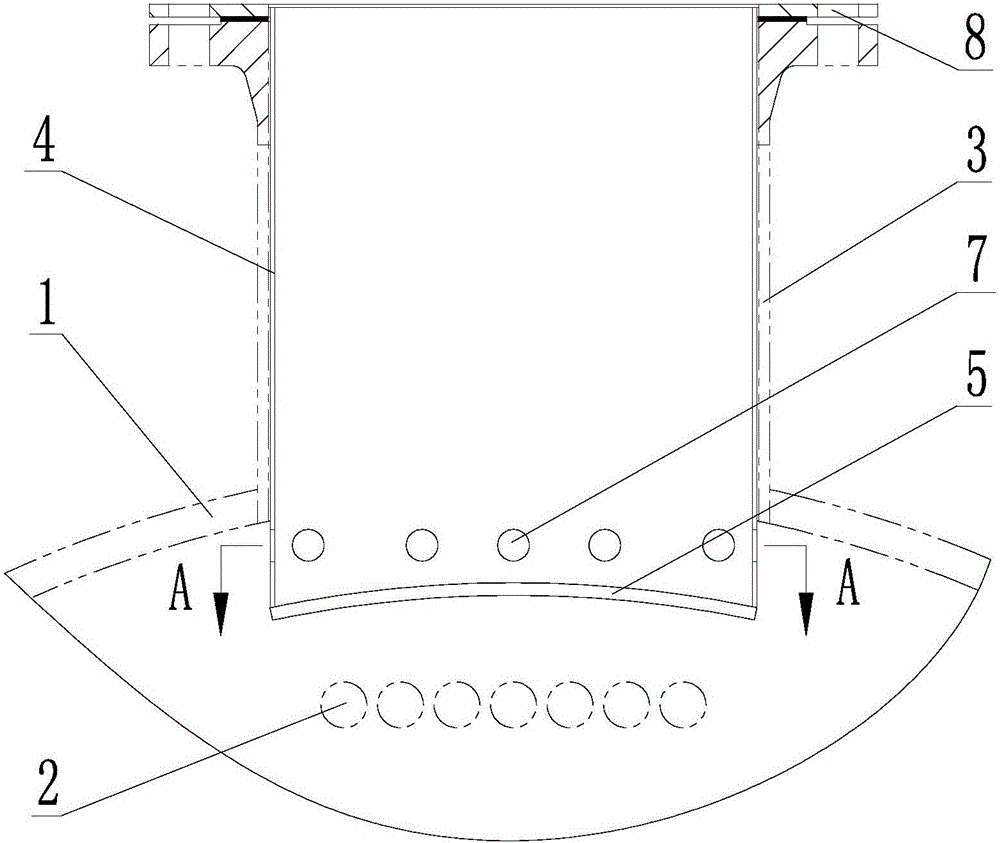

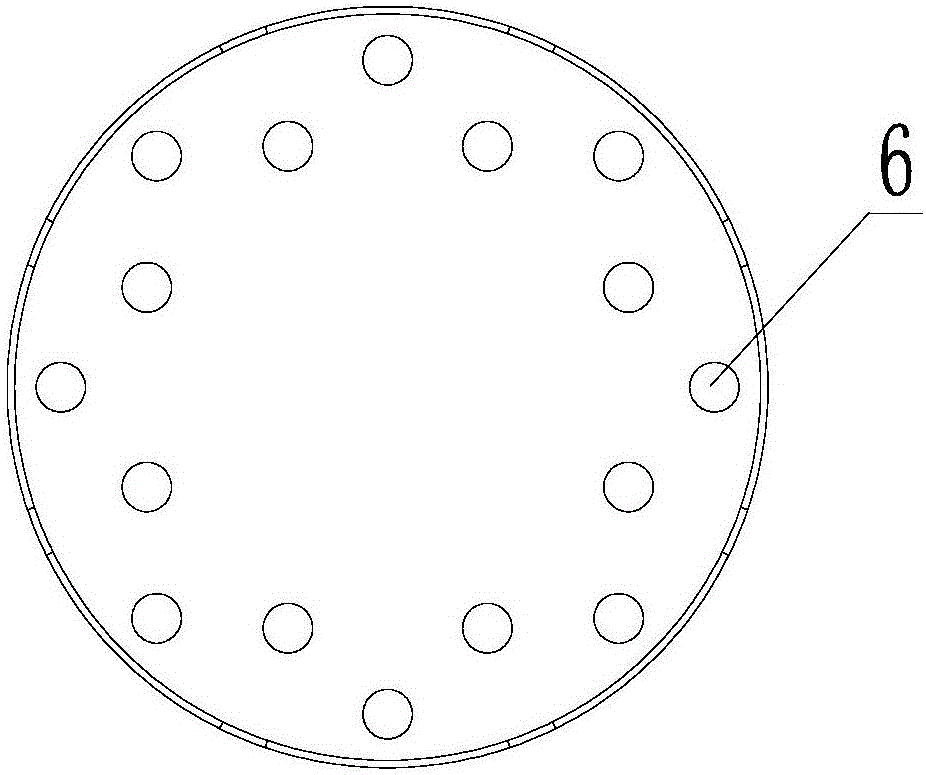

[0020] see Figure 1-2 As shown, the above-mentioned anti-scouring mechanism for the heat exchanger is arranged at the fluid inlet of the shell side of the heat exchanger to reduce the vibration and abrasion caused by the direct scour of the fluid to the heat exchange tube 2 .

[0021] The heat exchanger includes a first cylinder body 1 distributed in the vertical direction, a plurality of heat exchange tubes 2 arranged in the first cylinder body 1 distributed in the vertical direction, and a plurality of heat exchange tubes 2 arranged on the side wall of the first cylinder body 1 The feed port for passing into the heat exchange medium, and the feed pipe 3 communicated with the feed port. In this embodiment, the feed pipes 3 are distributed along the horizontal direction.

[0022] The anti-shock mechanism includes a second cylinder 4 that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com