Cold Blasting Method of Liquid Carbon Dioxide in Closed Blasting Hole

A technology of liquid carbon dioxide and carbon dioxide, which is applied in blasting and other directions, can solve the problems of low blasting power and high cost, and achieve the effect of high blasting power, simple and convenient construction, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

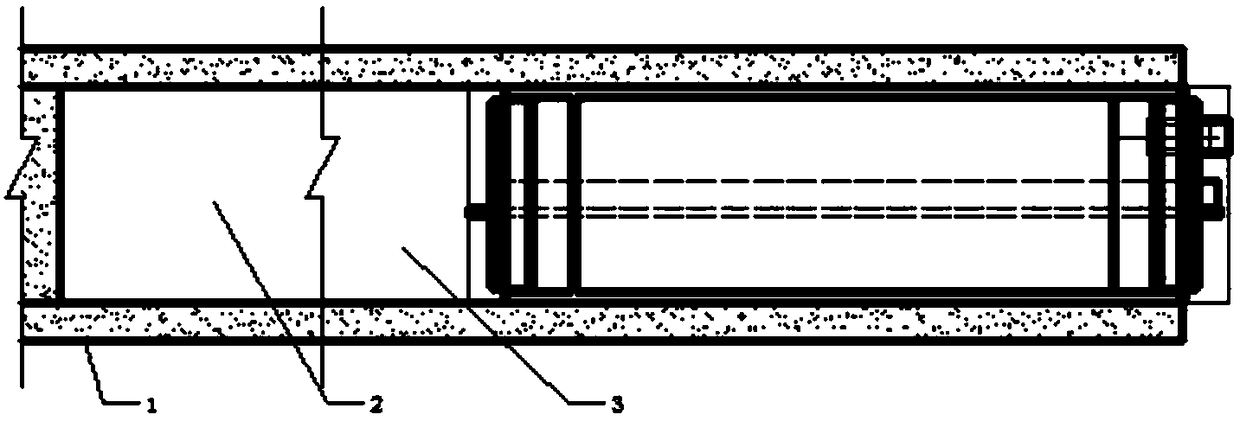

[0027] This embodiment provides a liquid carbon dioxide cold blasting method for a closed blast hole, and the specific steps are as follows:

[0028] S1: According to the needs of rock blasting, design parameters such as the number of blast holes, hole layout, hole size, depth, azimuth, inclination, etc., and drill blast holes on the rock to be blasted to complete the blast hole construction;

[0029] S2: Clean up the drilled rock blast holes to ensure that there are no residual broken rocks and other foreign matter in the holes;

[0030] S3: Install the hole sealing device, put the end of the hole sealing device with the detonator deep into the hole, the rubber part of the shell is completely submerged in the hole, and the high pressure liquid injection port, carbon dioxide liquid injection port, and lead pipe port are reserved outside the blast hole ;

[0031] S4: The high-pressure liquid injection port is connected to the high-pressure liquid injection gun, and the hole se...

Embodiment 2

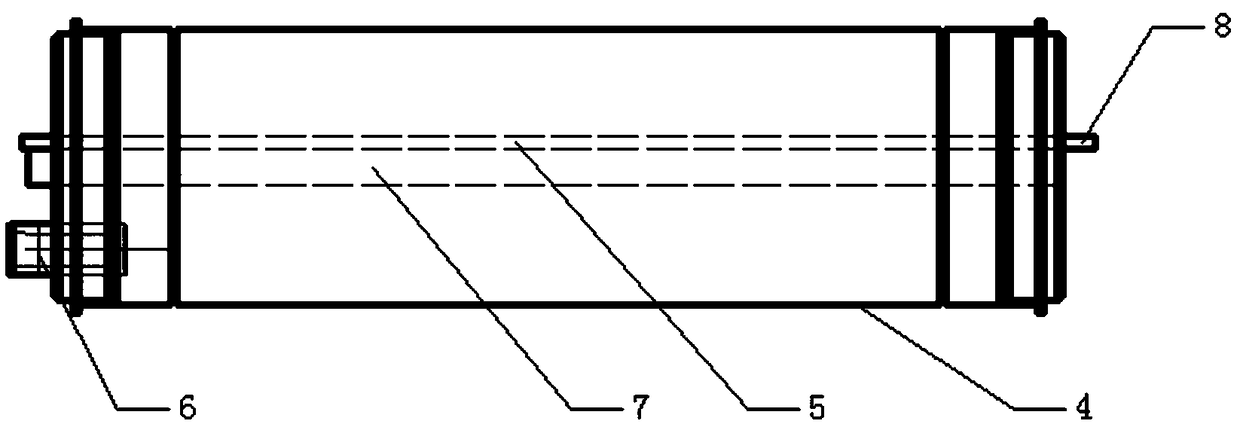

[0036] This embodiment provides a sealing device used in Embodiment 1, including: a housing, a lead tube, an initiator, an initiator wire, a high-pressure liquid injection port, a carbon dioxide liquid injection port, and a carbon dioxide liquid injection pipe; a high-pressure liquid injection The mouth, the carbon dioxide injection port, and the lead tube are placed at one end of the shell. The lead tube runs through the entire shell and protrudes from the other end of the shell. The end is equipped with a detonator. The lead tube is connected with the lead tube, and the carbon dioxide injection The pipe runs through the whole shell, and the carbon dioxide liquid injection port communicates with the carbon dioxide liquid injection pipe; the wire of the detonator is placed in the lead pipe and connected with the detonator.

[0037] Preferably, the carbon dioxide liquid injection port is located between the high-pressure liquid injection port and the lead pipe port.

[0038] Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com