Variable-speed rolling bearing fault recognition method based on order enveloping time-frequency energy spectrum

A rolling bearing and fault identification technology, which is applied in the testing of mechanical bearings, measuring devices, and mechanical components, etc., can solve the problems of high algorithm complexity, limited engineering application, low computing efficiency, etc., and achieves high computing efficiency and low hardware costs. , the effect of low algorithm complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

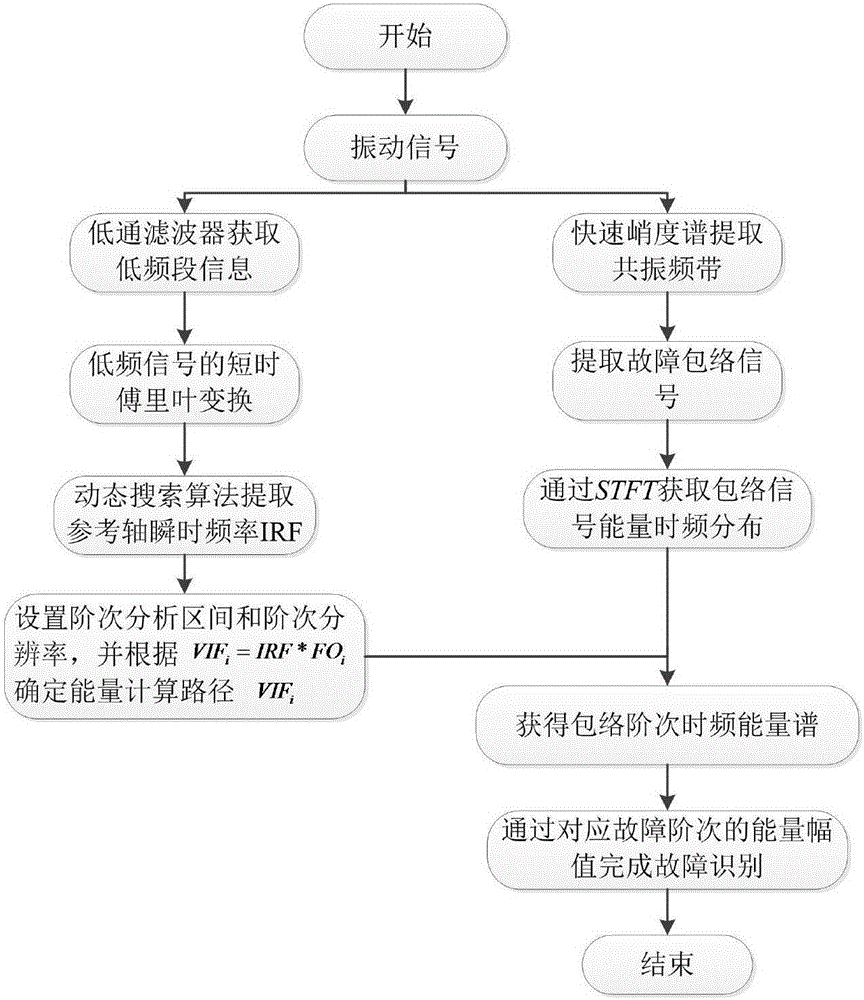

[0033] refer to figure 1 , a variable speed rolling bearing fault identification method based on the order envelope time-frequency energy spectrum, including the following steps:

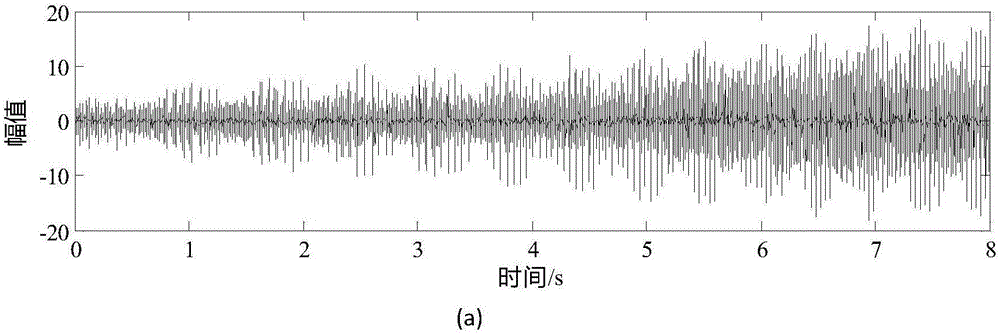

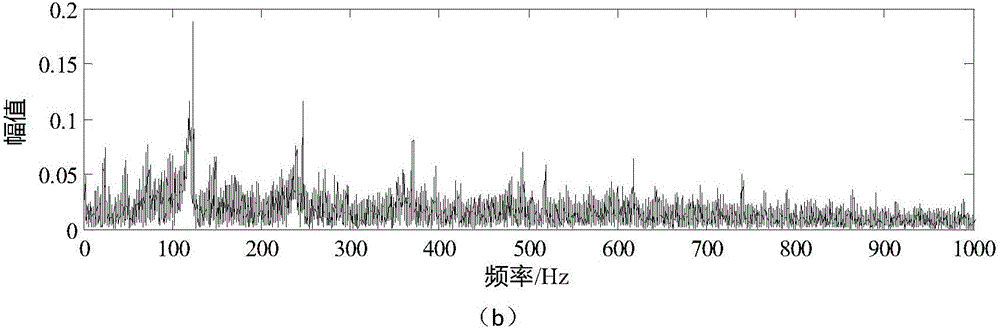

[0034] Step 1: Use the vibration acceleration sensor to collect the vibration signal x(t) of the rotating machinery, and set the sampling rate to f s , the rolling bearing vibration signals collected under variable speed conditions are as follows: figure 2 As shown in (a), the sampling frequency is 12800 Hz, and the sampling length is 8 s. Artificial injection is used to simulate the inner ring scratch fault. The envelope spectrum obtained by Hilbert envelope demodulation is as follows: figure 2 (b) the failure cannot be identified due to the presence of "frequency ambiguity" effects;

[0035] Step 2: Perform low-pass filtering on the collected vibration signal to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com