Nonuniform loading test device for simulating floor water inrush

A loading test device and non-uniform technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems that the base plate cannot provide an active hydraulic environment, the difference is large, and there is not much progress in comparative test research. Achieve the effect of improving reliability and practicability, simple device structure and easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

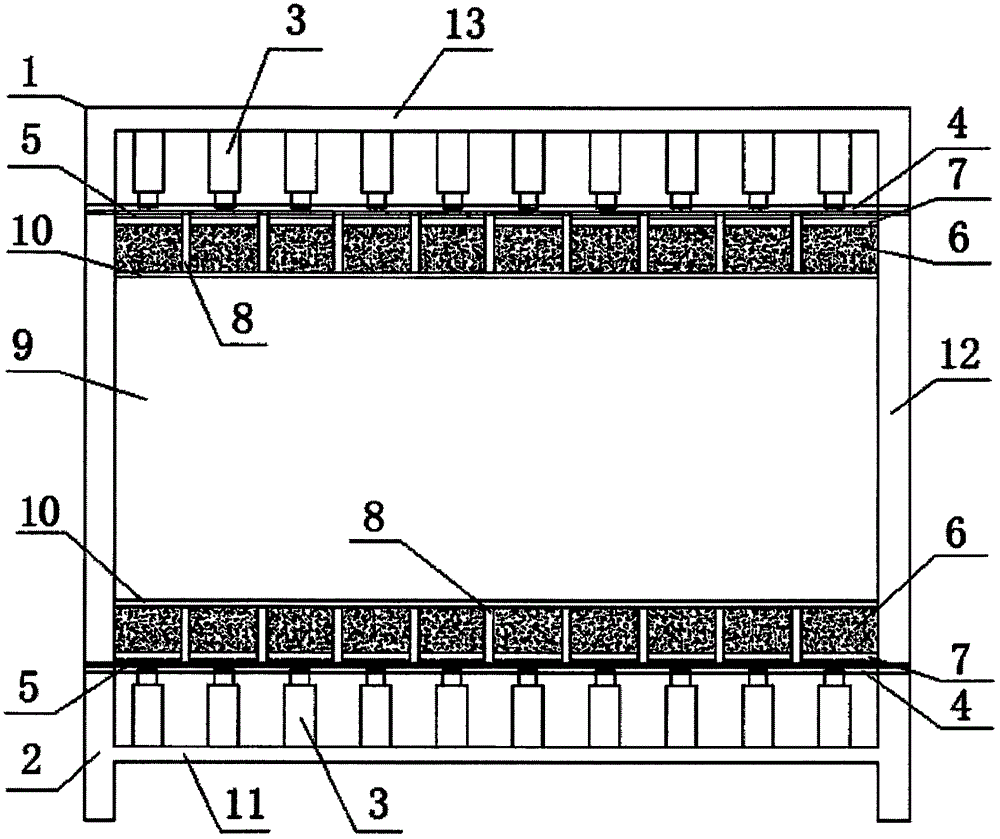

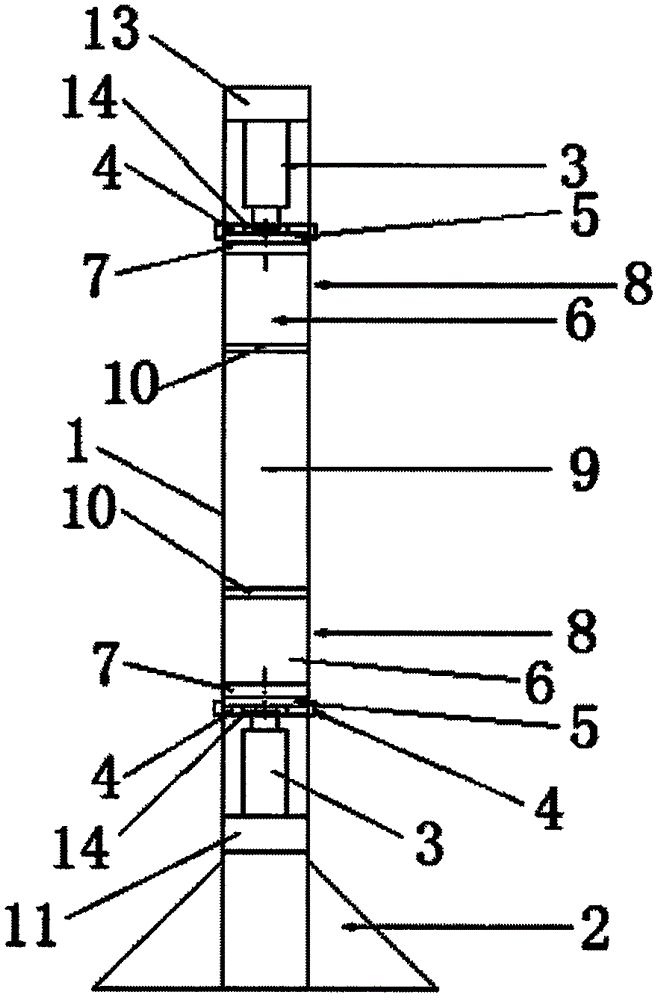

[0017] Such as figure 1 , 2 As shown, the non-uniform loading test device for simulating water inrush from the floor includes a test bench system, a loading system and a test system. The test system includes a pressure cell and a displacement meter, which are arranged in a similar Inside the material test model 9, the pressure cell and the displacement gauge are all connected to the computer through a data line, and it is characterized in that: the test bench system is composed of a test bench base 2, a test bench main body 1 and two hydraulic loading system frames. The main body 1 of the bench is a closed frame structure composed of a bottom beam 11, a top beam 13, side beams 12, and front and rear panels. The bottom beam 11 is installed on the base 2 of the test bench, and the top beam 13 is located The top and side beams 12 are installed between the bottom beam 11 and the top beam 13, and the front and rear panels are respectively fixed on the front and rear sides of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com