Insertion type near infrared probe and work method thereof

A working method, near-infrared technology, applied in the field of near-infrared analysis, can solve problems such as time-consuming and laborious uncertain factors, poor sampling operability of the sampler, and reduced accuracy of detection results, so as to improve detection accuracy, improve accuracy and Reliability, the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

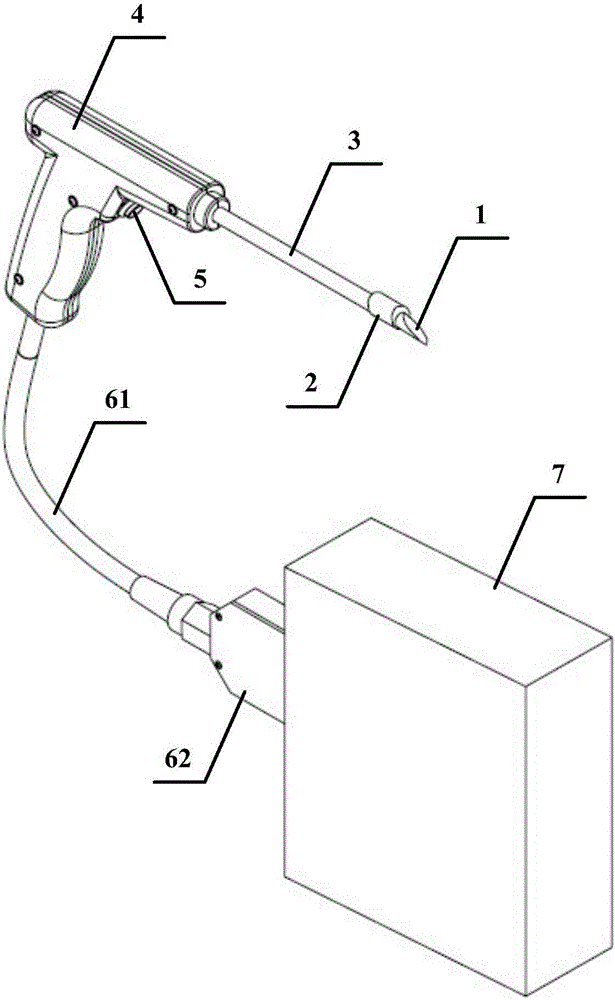

[0042] figure 1 Schematically provides a simplified structural diagram of the cutting-type near-infrared probe of this embodiment connected to the near-infrared analyzer, as shown in figure 1 As shown, the near-infrared probe includes:

[0043] Spike part 1, said spike part is located at the head of said near-infrared probe, and is used for inserting the sample to be tested;

[0044] Calibration system 2, the calibration system includes a standard light source and a temperature and humidity sensor, located at the rear end of the spike;

[0045] Insertion rod 3, described insertion rod connects described calibration system and hand-held part;

[0046] Hand-held part 4, described hand-held part is connected with optical fiber assembly, and near-infrared probe can carry out signal transmission with near-infrared analyzer 7 through described optical fiber assembly; Described optical fiber assembly includes optical fiber 61 and optical fiber connector 62;

[0047] A switching mo...

Embodiment 2

[0064] An application example of the cutting-type near-infrared probe and its working method in Example 1 of the present invention in the field of grain quality monitoring.

[0065]In this application example, the sample to be tested is bagged grain (such as corn, wheat, etc.), and the spiked part is a sharp steel pipe with an opening at the head, which can be easily inserted into the grain bag; the insertion rod is made of sanitary stainless steel The steel pipe can be inserted into the grain, and the length of the insertion rod can be designed according to the needs to expand the range of grain detection points; the hand-held part is a pistol-shaped handle to improve the comfort of holding, of course, different shapes of the hand-held part can also be selected; the switching module is The button set on the hand-held part is convenient for control. The button can be one or two. In this application example, there is one button, and the calibration mode and the detection mode ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com