Metal material forged microstructure soft measurement method based on self-adaptive expert system

A technology of microstructure and metal materials, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem that metal material forging microstructure cannot be measured online, and achieve the effect of accurate and fast soft measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

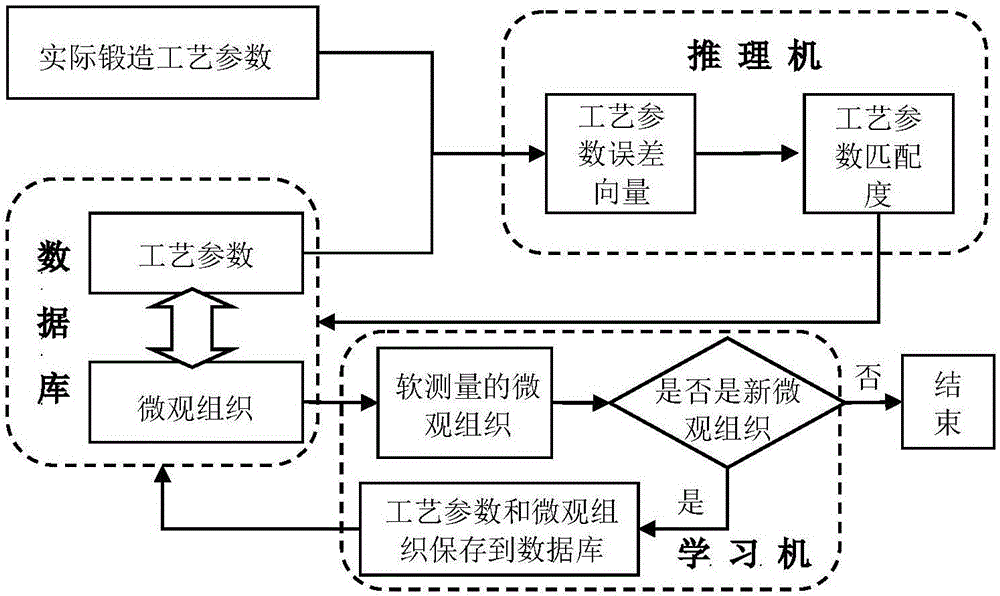

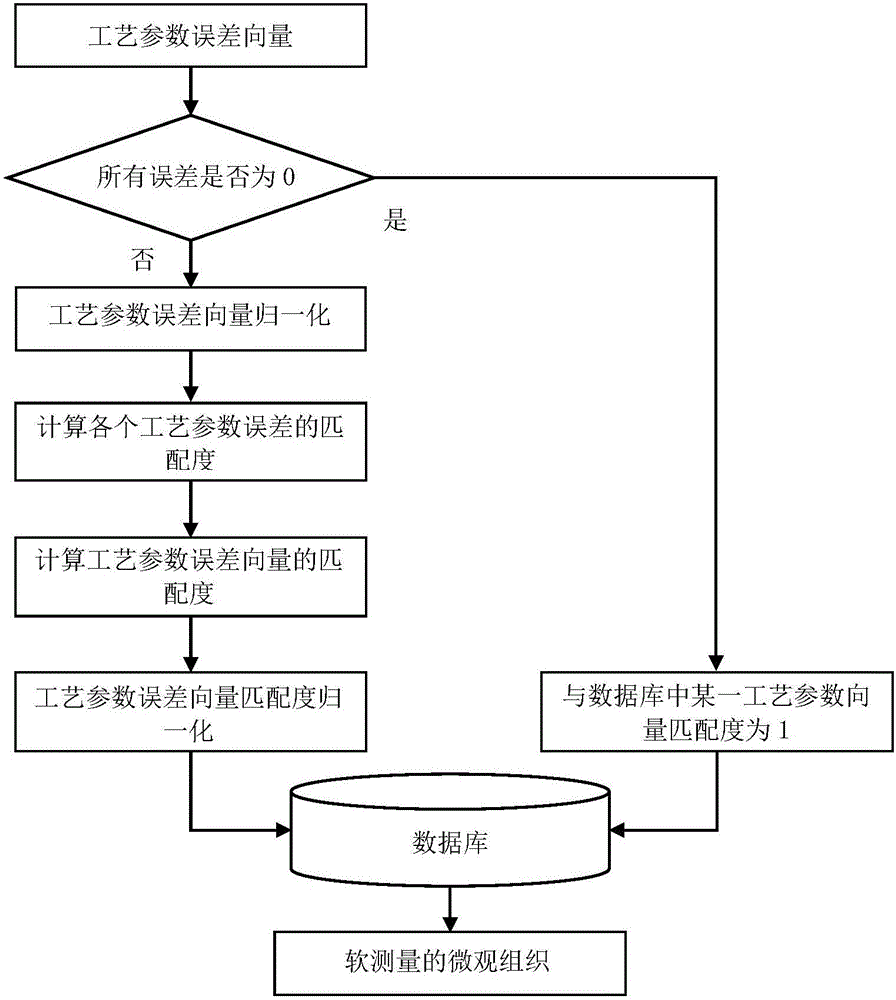

[0054] The present invention is a kind of metal material microstructure soft measuring method, and its flow chart is as follows figure 1 shown. The implementation details of the metal material microstructure soft-sensing method involved in the present invention are described in detail below, and the method includes:

[0055] Step 1: Establish an initial expert system based on historical forging process parameters (upper die speed and displacement, forging temperature) and metal material microstructure data (recrystallization fraction and recrystallization grain size), mainly including database, reasoning machine and learning machine;

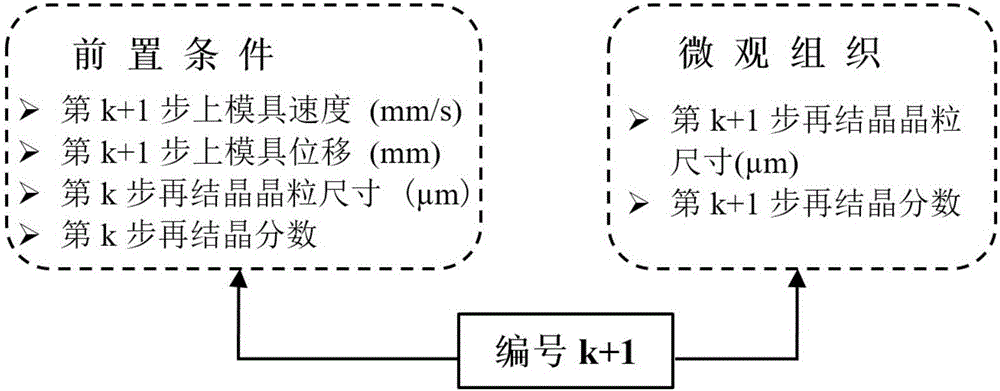

[0056] The database is established based on historical forging process parameters (upper die speed and displacement, forging temperature) and microstructure data (recrystallization grain size and recrystalliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com