Method for electric submersible pump well working fluid level calculation based on ground real-time monitoring electrical parameters

A submersible electric pump, ground measurement technology, applied in the direction of calculation, electric digital data processing, design optimization/simulation, etc., can solve the problem that the dynamic liquid level cannot be monitored in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

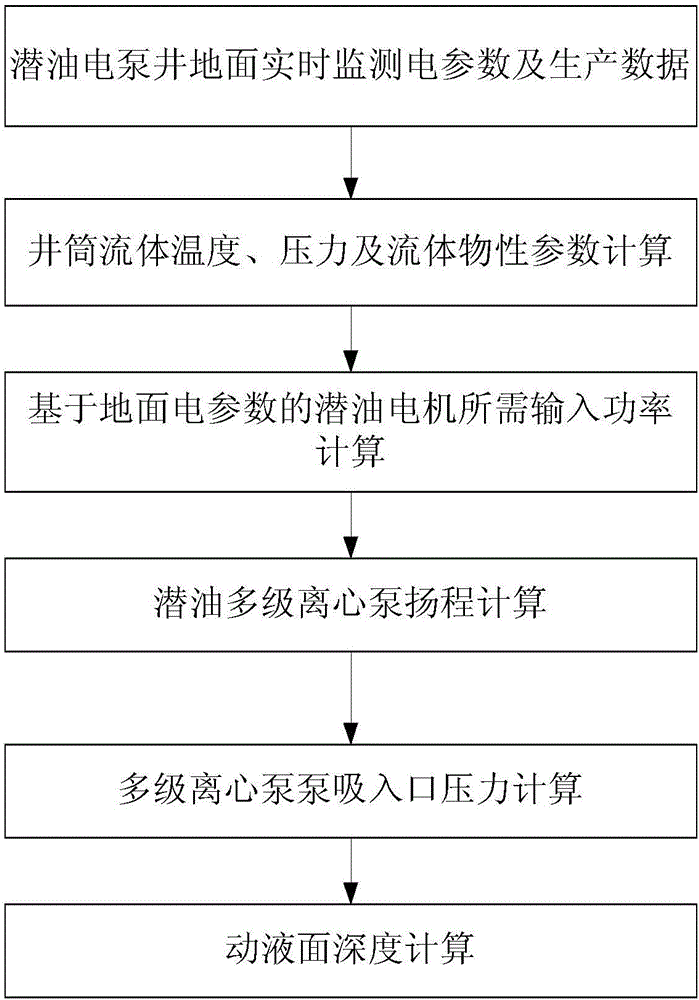

Method used

Image

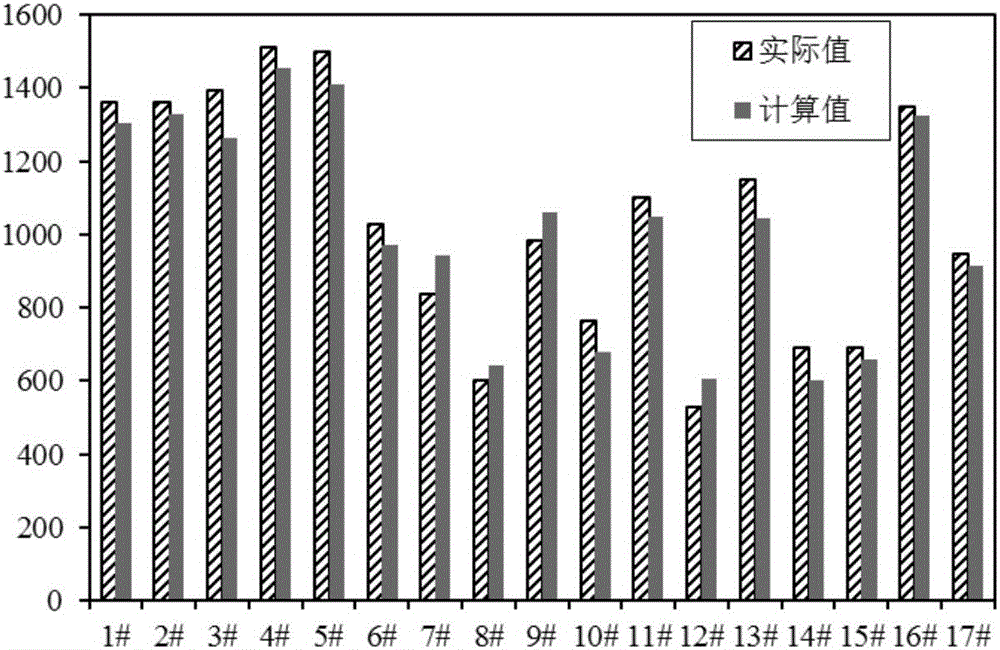

Examples

Embodiment 1

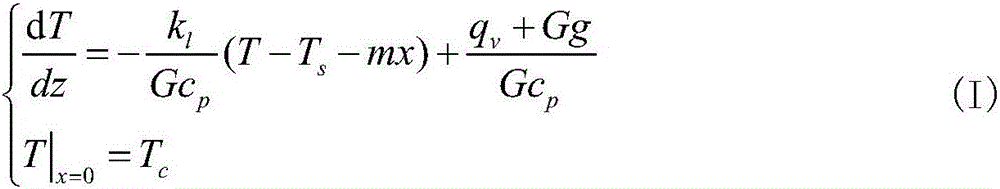

[0060] Step 1: Using the "four-stage method" to establish a calculation model for the wellbore fluid temperature of a submersible electric pump well

[0061] During the production process of electric submersible pump wells, the thermal radiation of gas above the liquid surface in the oil casing annulus, the heat conduction of liquid below the liquid surface, and the heating of motors and cable equipment affect the temperature and flow law of the wellbore fluid. Based on the actual physical model of the electric submersible pump well, the following assumptions are put forward:

[0062] (1) The heat transfer process is a steady-state heat transfer process in the wellbore and an unsteady-state heat transfer process in the formation;

[0063] (2) The flow in the well is one-dimensional steady flow;

[0064] (3) The formation temperature around the wellbore is affected by the geothermal gradient and changes linearly with depth;

[0065] (4) The cable is a linear heat source with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com