LCM (LCD Module) assembly appearance defect detection method based on 3D imaging technology

A defect detection and component technology, applied in image enhancement, image analysis, image data processing and other directions, can solve the problems of high cost, inaccurate inspection results, low efficiency and accuracy, and achieve high accuracy, high inspection efficiency, The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

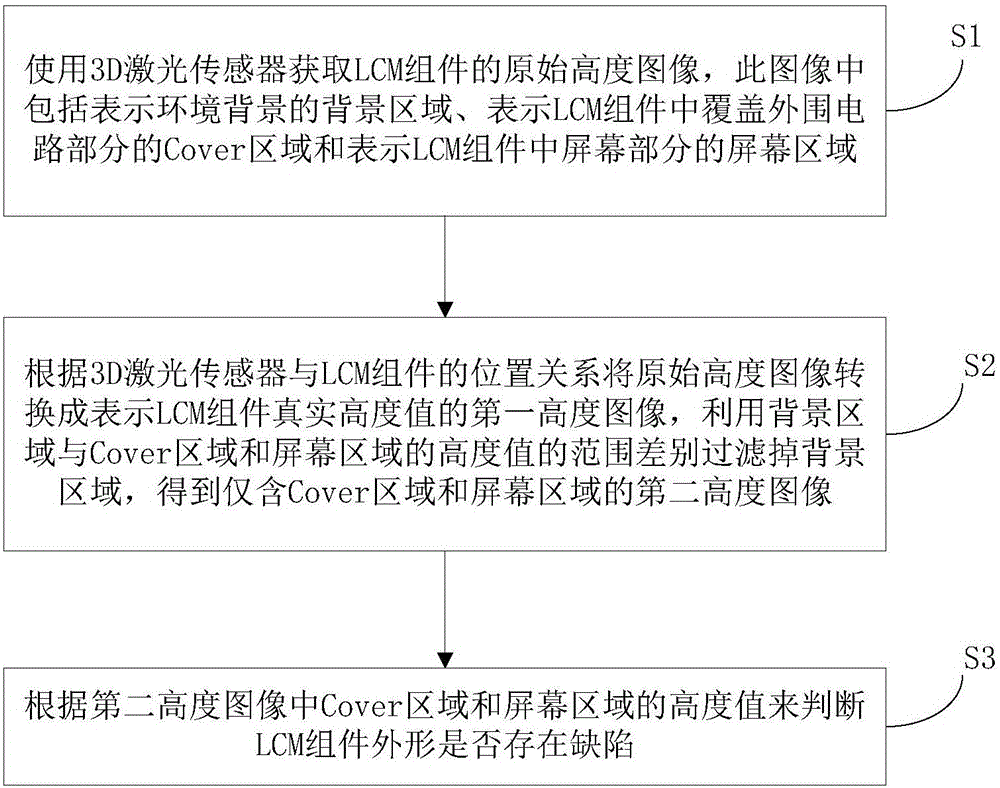

[0042] Such as figure 1 with figure 2 As shown, an LCM component shape defect detection method based on 3D imaging technology includes the following steps:

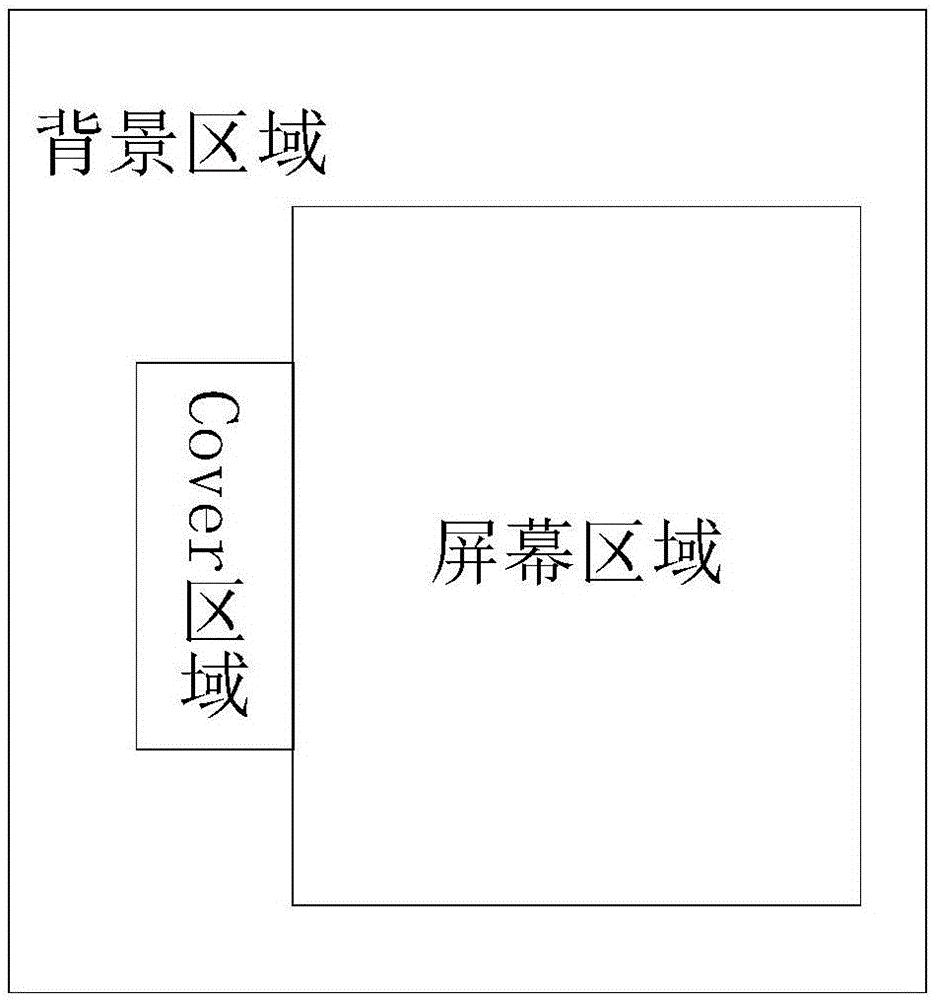

[0043] S1: Use a 3D laser sensor to obtain the original height image of the LCM component, which includes the background area representing the environmental background, the Cover area representing the part of the LCM component covering the peripheral circuit, and the screen area representing the screen portion of the LCM component;

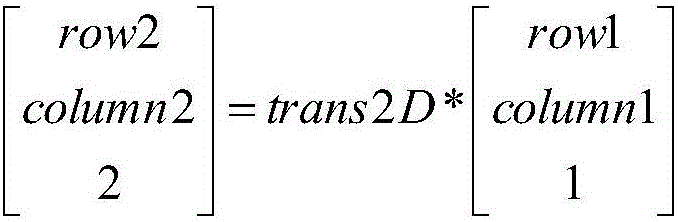

[0044] S2, according to the positional relationship between the 3D laser sensor and the LCM component, the original height image is converted into the first height image representing the true height value of the LCM component, and the background area is filtered out by using the difference in the height value range of the background area, the Cover area and the screen area, Obtain a second height image containing only the Cover area and the screen area;

[0045] S3: Determine whether the shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com