Multi-gear vacuum on-load tap switch

An on-load tap, multi-gear technology, used in electrical switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc. , shifting gears and other problems, to achieve the effect of prolonging the service life and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

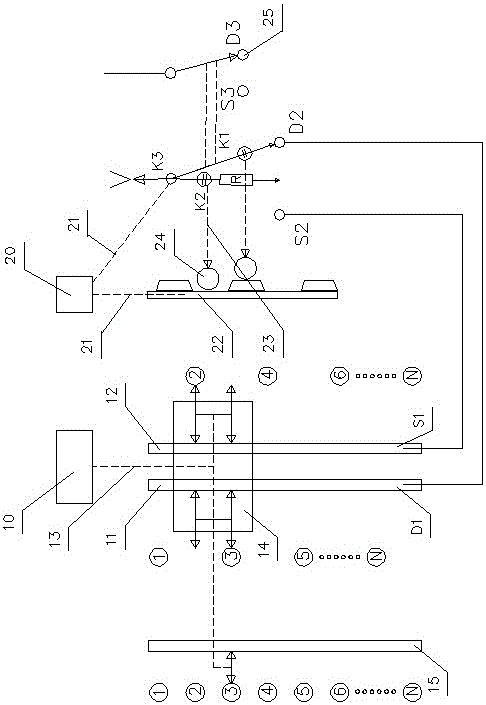

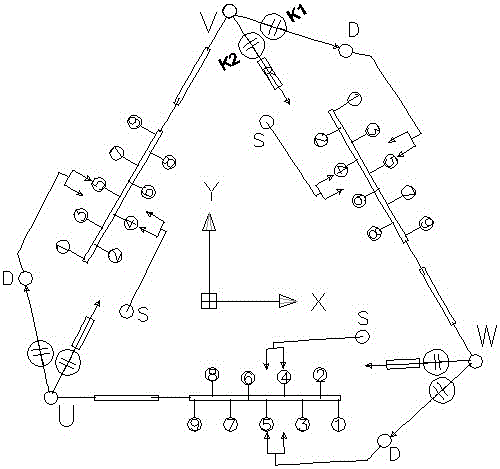

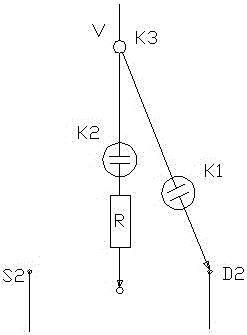

[0031] Such as figure 1 As shown, the multi-gear vacuum on-load tap-changer of the present invention is composed of a switch part and a selector switch part, and the switch part includes a gear position composed of a stepping motor 10, a screw rod 13, and a screw rod pair 14. Switch the drive mechanism and the static contact group composed of multiple sets of static contacts.

[0032] The static contacts are arranged at both ends of the screw rod respectively, and the odd and even numbers of static contacts are arranged alternately. The moving contact module is arranged on the screw pair. The moving contact module includes two independent moving contacts fixed on the screw pair, and the moving contact conductive rods 11 and 12. The two independent moving contacts are divided into It is an odd-number moving contact and an even-number moving contact, cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com