Method for verifying center deviation position of dynamic wafer in AWC (Active Wafer Centering) system

A technology for verifying dynamics and wafers, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as not including wafers, difficult coordination of mutual positional relationship between manipulators, increased verification complexity, etc., to achieve the goal of improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

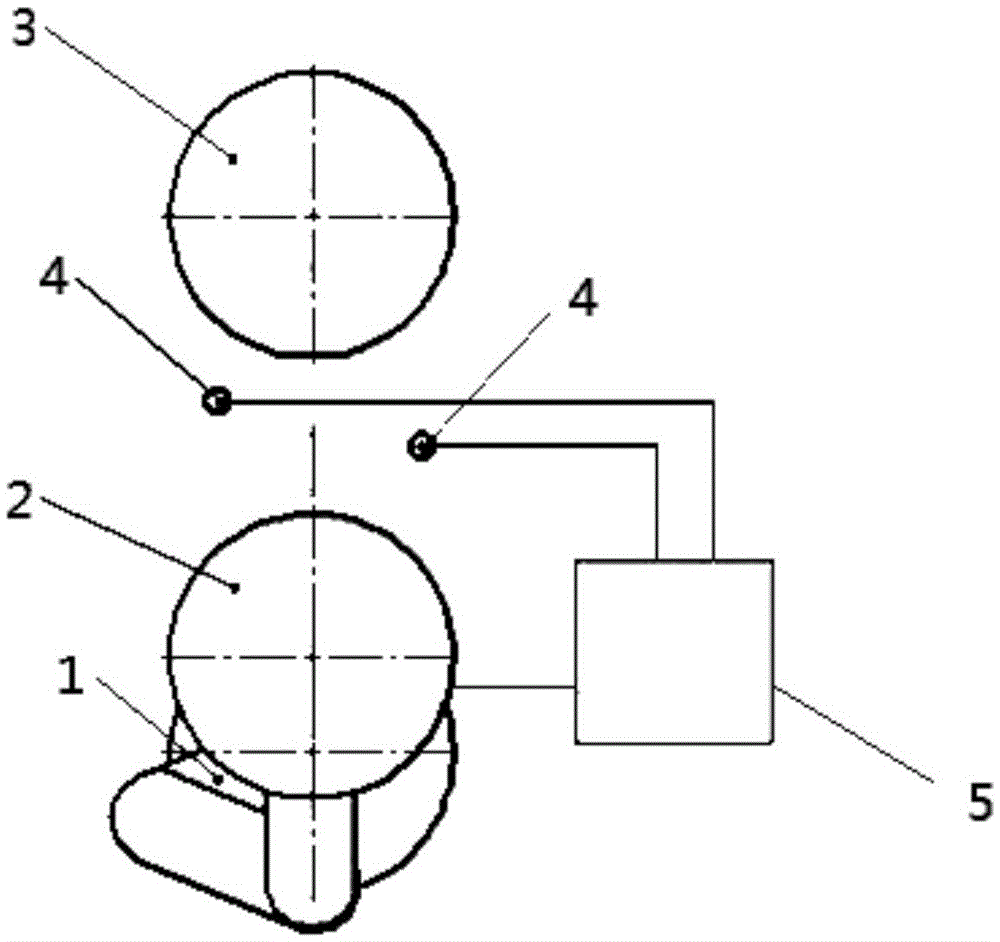

[0028] Such as figure 1 As shown, the AWC system in the prior art generally includes a manipulator 1 , a wafer 2 , a station 3 , a sensor 4 , and a manipulator controller 5 .

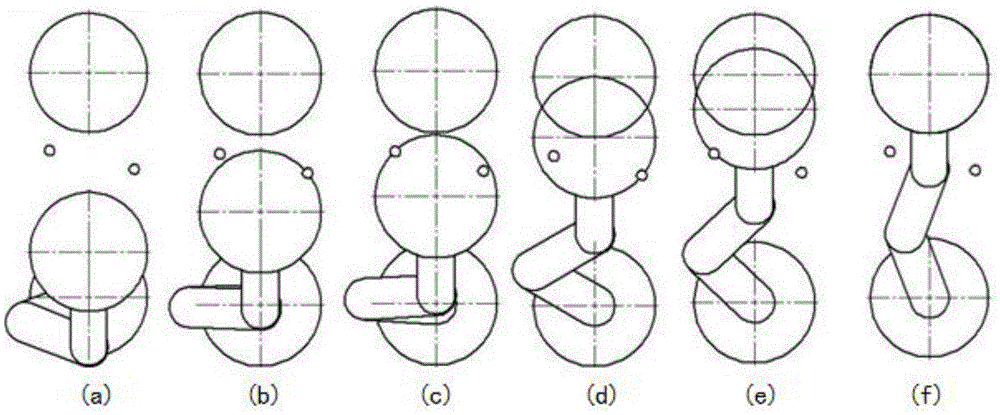

[0029] Such as figure 2 As shown, the relationship between the wafer transfer process and the sensor position in the prior art: in the taught direction, when the manipulator extends from a to f, it is a collection process; when the manipulator retracts from f to a, it is another collection process One collection process. Repeated several times, through a specific algorithm, the manipulator controller completes the zero reference calibration and stores it. After that, each time the manipulator carries the wafer in the same teaching direction (when the wafer is offset relative to the manipulator) and passes the through-beam sensor, AWC will give the deviation result of the waf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com