Piezoelectric ceramic actuator piece and preparation method thereof

A technology of piezoelectric ceramic actuation and piezoelectric ceramic sheet, which is applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc. The performance of the moving piece is unstable and other problems, to achieve the effect of dense and stable connection, stable performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

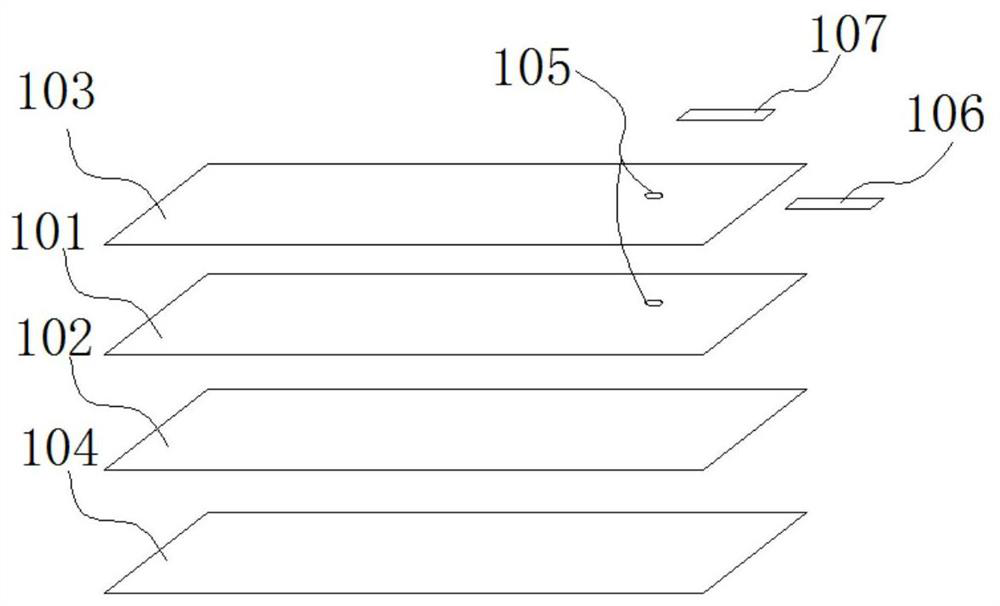

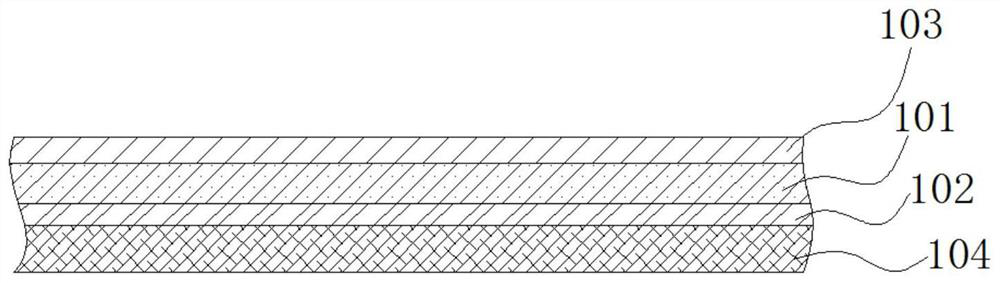

[0033] figure 1 A schematic diagram of the exploded structure of the piezoelectric ceramic actuator piece provided in Embodiment 1 of the present invention; figure 2 for figure 1 The structural schematic diagram of the cross-section of the piezoceramic actuator piece shown; figure 1 and figure 2 As shown, the piezoelectric ceramic actuating piece provided by the embodiment of the present invention includes a first piezoelectric ceramic piece and a toughened ceramic substrate 102, and the first piezoelectric ceramic piece includes a first ceramic piece 101 and is respectively arranged on the first ceramic piece 101. The first external electrode sheet 103 and the first internal electrode sheet 104 on the upper and lower surfaces, the toughened ceramic substrate 102 is arranged below the first internal electrode sheet 104, and the first piezoelectric ceramic sheet and the toughened ceramic substrate 102 are integrally co-fired .

[0034] In the piezoelectric ceramic actuati...

Embodiment 2

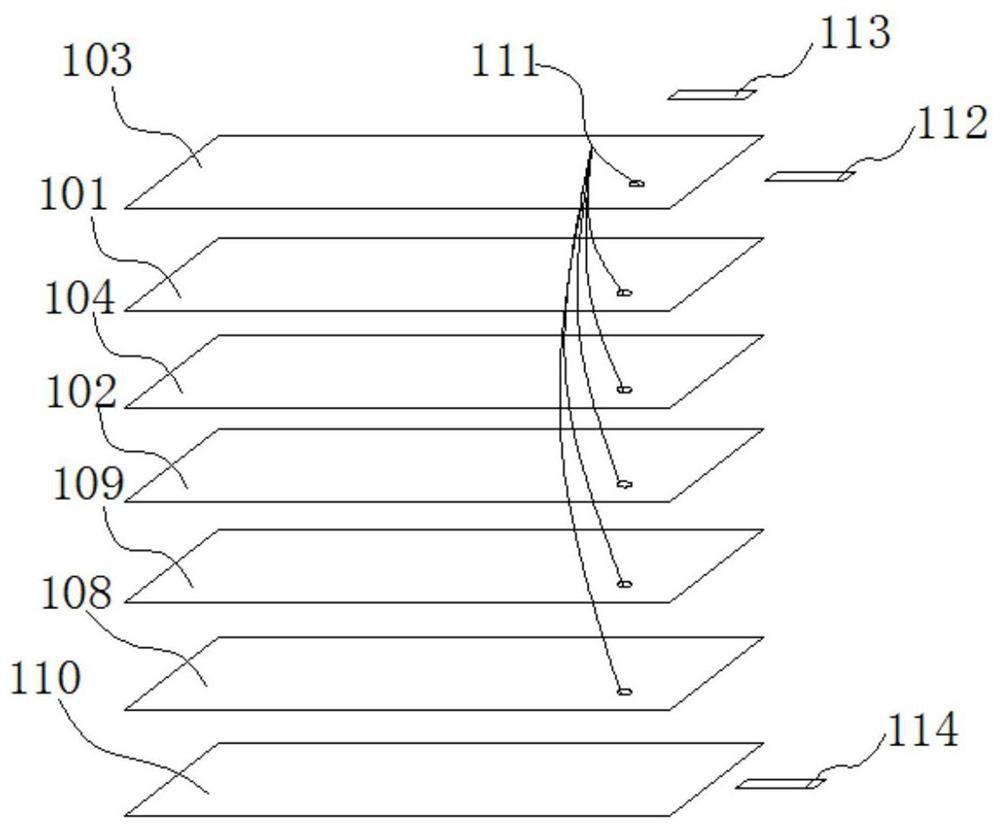

[0059] image 3 A schematic diagram of the exploded structure of the piezoelectric ceramic actuator piece provided by Embodiment 2 of the present invention; Figure 4 for image 3 Schematic cross-sectional view of the piezoceramic actuator piece shown. Such as image 3 and Figure 4 As shown, this embodiment also provides a piezoelectric ceramic actuator. This embodiment is a further improvement on the basis of Embodiment 1. The technical solution described in Embodiment 1 also belongs to this embodiment. Embodiment 1 has The described technical solutions will not be described repeatedly.

[0060] The piezoelectric ceramic actuating piece provided in this embodiment also includes a second piezoelectric ceramic piece, and the second piezoelectric ceramic piece includes a second ceramic piece 108 and a second internal electrode piece 109 respectively arranged on the upper and lower surfaces of the second ceramic piece 108 and the second external electrode sheet 110 , the se...

Embodiment 3

[0083] Figure 5 A schematic diagram of the exploded structure of the piezoelectric ceramic actuating piece provided in Embodiment 3 of the present invention; Figure 5As shown, the difference between this embodiment and embodiment 2 is that in embodiment 2, a third pad 112, a fourth pad 113 and a fifth pad 114 are provided, while this embodiment is provided with a sixth pad pad 117, the seventh pad 118, the eighth pad 119 and the ninth pad 120, wherein the sixth pad 117 is connected to the first external electrode sheet 103, and the seventh pad 118 is connected to the first internal electrode sheet 104 , the eighth pad 119 is connected to the second internal electrode sheet 109 , and the ninth pad 120 is connected to the second external electrode sheet 110 .

[0084] By setting the sixth bonding pad 117, the seventh bonding pad 118, the eighth bonding pad 119 and the ninth bonding pad 120, the piezoelectric ceramic actuating sheet provided in this embodiment can be connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com