Bidirectional tempering and thermal runaway anti-diffusion device for automobile power battery

A technology for automotive power batteries and thermal runaway, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems of uneven flow of coolant, high safety factor, and easy interference with circuits, so as to avoid thermal runaway and control The effect of own temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

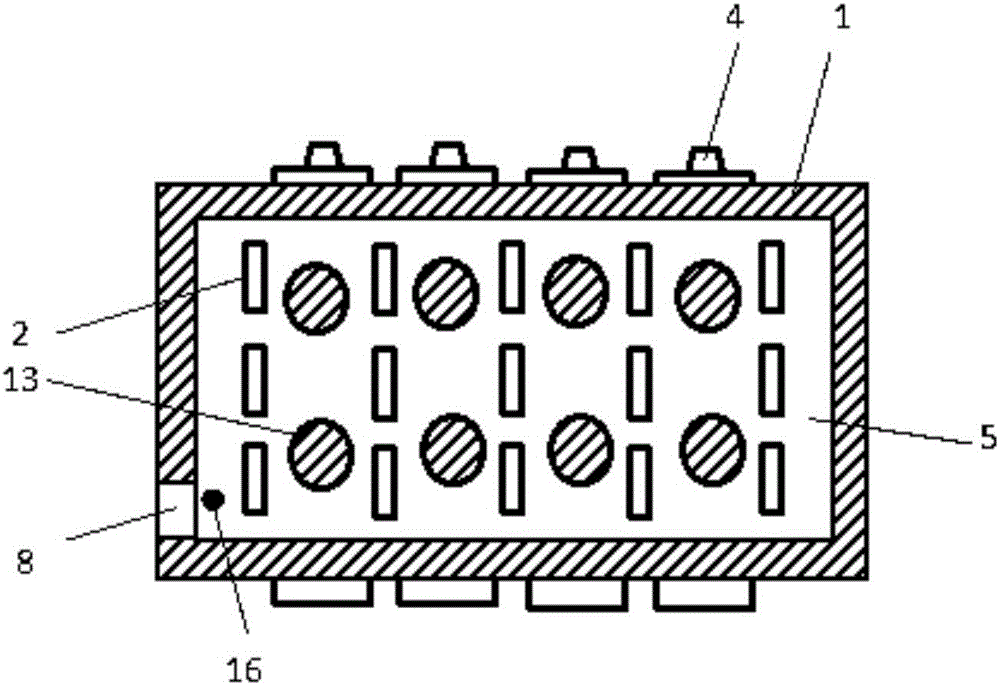

[0071] Such as figure 1 In the shown embodiment of a plan A, several batteries 4 are tightly spaced in a matrix form on the square heat-conducting substrate 1, and the number of batteries 4 in each row is 4, and the fluid through holes 2 are axially connected to the batteries 4. The axial directions are perpendicular to each other, and the fluid through holes 2 are arranged in a matrix shape 5X3 on both sides of each row of batteries 4. The fluid through holes 2 between adjacent batteries 4 are shared, and the cross section of the fluid through holes 2 is vertical along the axis of the battery 4. The narrow rectangular arrangement, that is, the opening size of the fluid through hole 2 along the axial direction of the battery 4 is larger than the opening size perpendicular to the axial direction of the battery 4. On the premise of taking into account the mechanical shock resistance performance of the heat-conducting matrix and the output power of the battery module per unit volu...

Embodiment 2

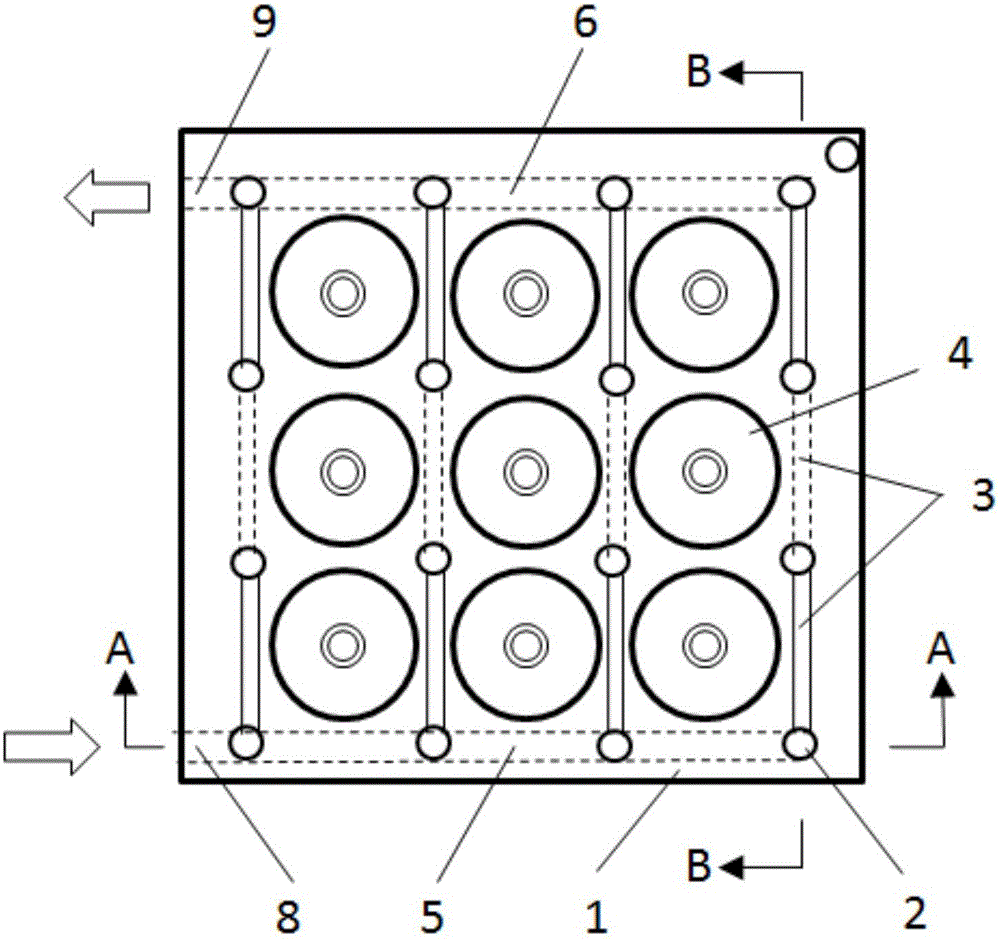

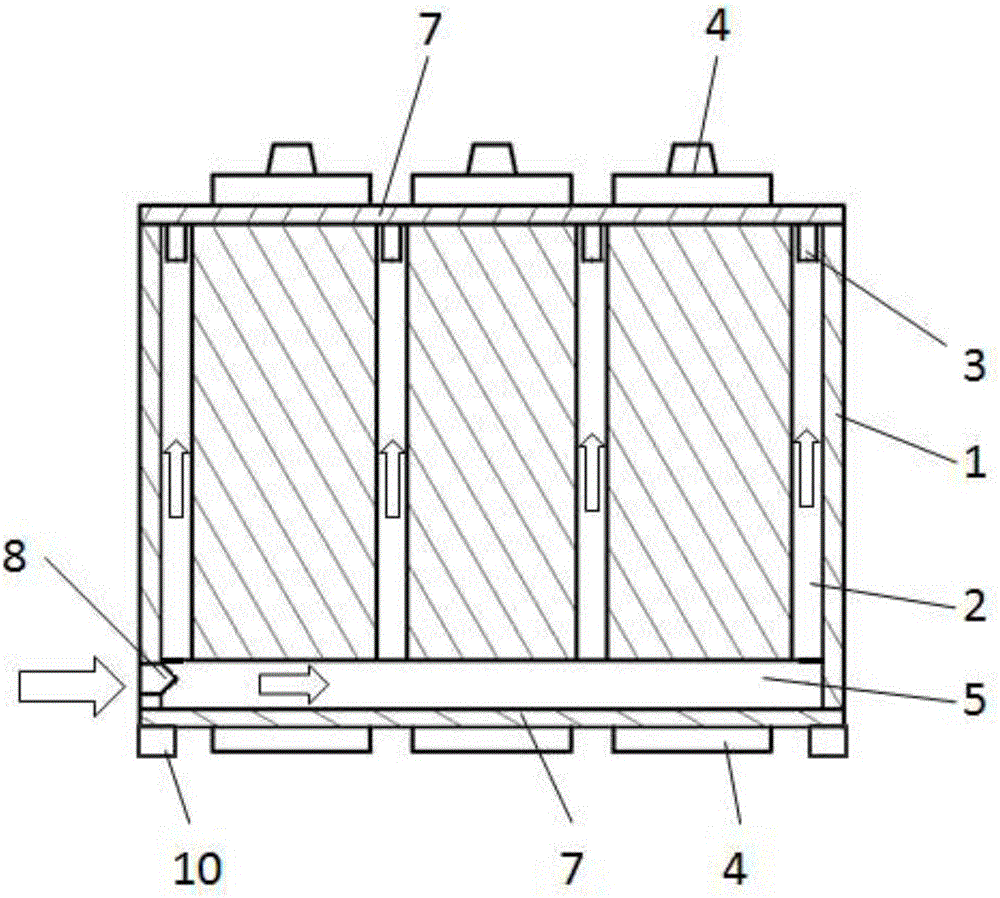

[0075] Such as Figure 2-5 In the shown embodiment of a B scheme, 9 batteries 4 are tightly spaced in a matrix-like vertical space on the square heat-conducting substrate 1, and the axial direction of the battery 4 is parallel to the axial direction of the circular fluid through hole 2. Each battery 4 is located at the center of four fluid through holes 2 , and the fluid through holes 2 between adjacent batteries 4 are shared.

[0076] Corresponding to the ports of the fluid through holes 2 located on the outer surfaces of the top side and the bottom side of the heat conduction substrate 1, a number of connection grooves 3 are opened on the outer surfaces of the two sides respectively, and the cross sections of the connection grooves 3 are vertically arranged along the axial direction of the battery 4 The rectangle, that is, the opening width of the connecting groove 3 is less than the opening depth, such as image 3 As shown; the two ends of the connection groove 3 are conne...

Embodiment 3

[0083] Such as Figure 6 In another B-plan embodiment shown, 9 batteries 4 are tightly spaced in a matrix-like vertical space on the block-shaped heat-conducting substrate 1. The axial direction of the battery 4 and the axial direction of the fluid through hole 2 are parallel to each other. Each The battery 4 is located at the center of the four fluid through holes 2, and the fluid through holes 2 between adjacent batteries 4 are shared;

[0084] Corresponding to the ports of the fluid through holes 2 located on the outer surface of the top side and the bottom side of the heat conduction base 1, a number of connection grooves 3 are opened on the outer surfaces of the two sides respectively, and the two ends of the connection groove 3 are connected to two fluid through holes 2 located on the heat conduction base 1 The ports on the outer surface of the same side connect all the fluid through holes 2 in the heat conduction base 1 into four parallel flow channels, and the four flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com