EtherCAT motor driver and master station clock synchronization method

A motor driver, master station technology, applied in electrical components, time division multiplexing systems, multiplexing communications, etc., can solve the problem of weak processing performance, high performance requirements, and complex MCU software architecture of the motor driver main controller. and other problems to achieve the effect of preventing the motor from running out of control and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

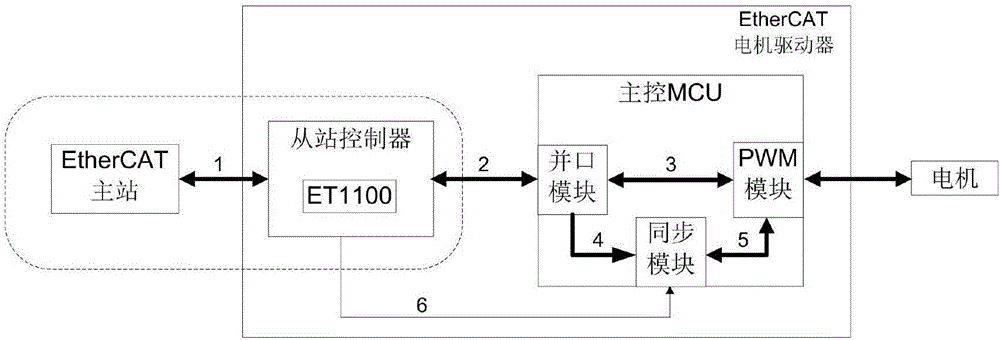

[0035] Such as figure 1 Shown is a structural diagram of a drive control system according to a specific embodiment of the present invention. The drive control system includes an EtherCAT master station, an EtherCAT motor controller and a motor. Wherein the EtherCAT motor controller includes a slave station controller (the hardware chip of ET1100 is adopted in this specific embodiment) and a main control MCU, and the main control MCU includes a parallel port module, a synchronization module and a PWM module.

[0036] figure 1 The arrow 1 shown is the real-time data interaction between the EtherCAT master station and the slave station controller, which mainly completes the real-time position / speed / torque data interaction and the real-time compensation of the distributed clock (DC) in the network;

[0037] Arrow 2 is the paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com