Clamping unit and chuck unit of clamping device

A chuck and clamping cylinder technology, applied in the field of clamping units, can solve problems such as operator danger, damage to processing machinery, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

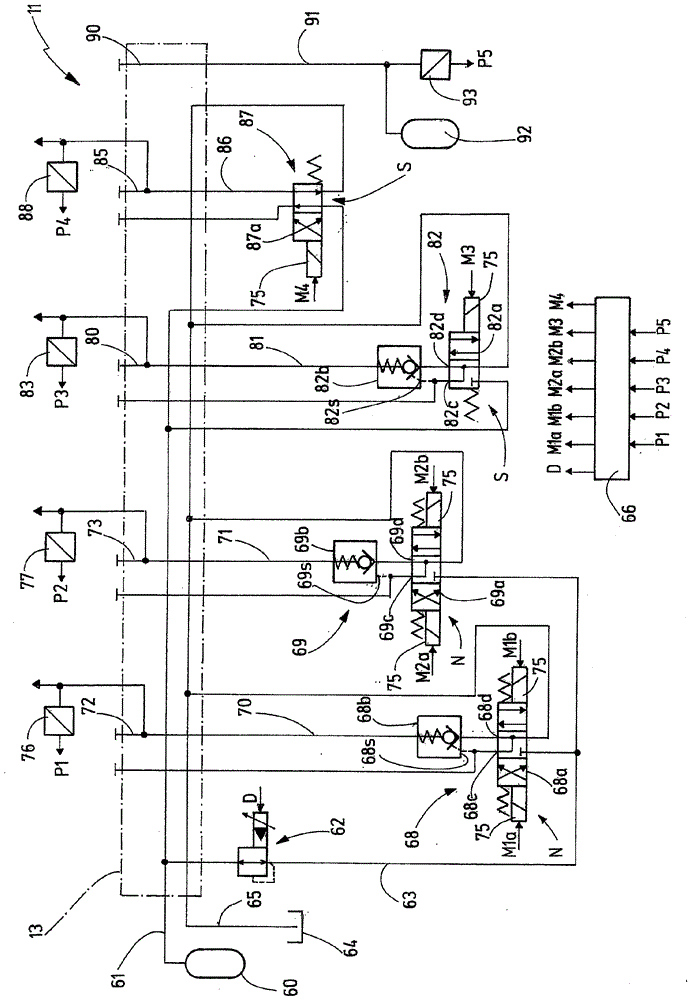

[0044] exist figure 1 A clamping device 10 with a clamping unit 11 and a chuck unit 12 is schematically shown in . The clamping unit 11 and the chuck unit 12 are fluidly and mechanically connectable to each other. For this purpose, the clamping unit 11 has a connecting device 13 and the chuck unit has a coupling device 14 , which cooperate in order to establish a mechanical and fluid connection.

[0045] A workpiece 15 can be clamped and held via the chuck unit 12 . The chuck unit 12 has clamping jaws 19 that are movable towards and away from each other. Preferably, the clamping jaws 19 are movable radially inwards or outwards relative to the longitudinal center axis of the chuck unit 12 in a common plane. The chuck unit 12 can have a carrier plate 25 , which carries the chuck unit 12 and is interposed, in particular for the mechanical connection, when establishing a connection with the clamping unit 11 . For manual operation, the carrier plate 25 is detachably connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com