Belt for drive systems, in particular a belt-like tension element for elevator systems, with flame-retardant properties

A belt and technology technology, applied in the belt field of drive technology, can solve the problems of expensive manufacturing process, complicated belt structure, etc., and achieve the effect of non-flammable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

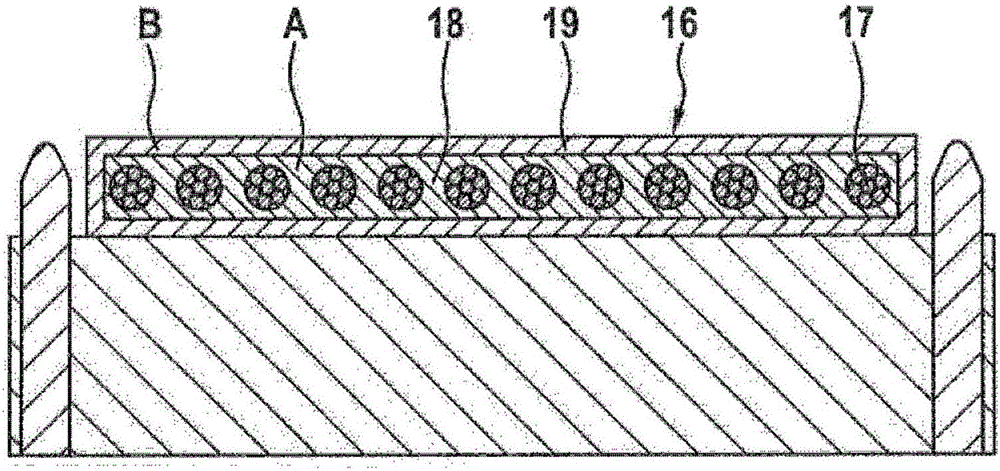

[0030] figure 1 A belt 16 is shown as traction element for elevator technology, in particular in the form of a flat belt. Material A is preferably polyurethane and forms the belt core 18 . The coating 19 consists of material B, which is preferably a mechanically high-stress PU varnish. In this case, the tension carrier 17 is embedded in the belt core 18 while being completely sheathed by the first material A. As shown in FIG. The tensile carrier 17 is preferably a tensile carrier made of steel. In a particularly preferred embodiment, the coating 19 completely surrounds the belt core 18 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com