Chromatic confocal system

A technology of focal length and wavelength, applied in the direction of die cups, instruments, catheters, etc., can solve the problem of inaccurate measurement data, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

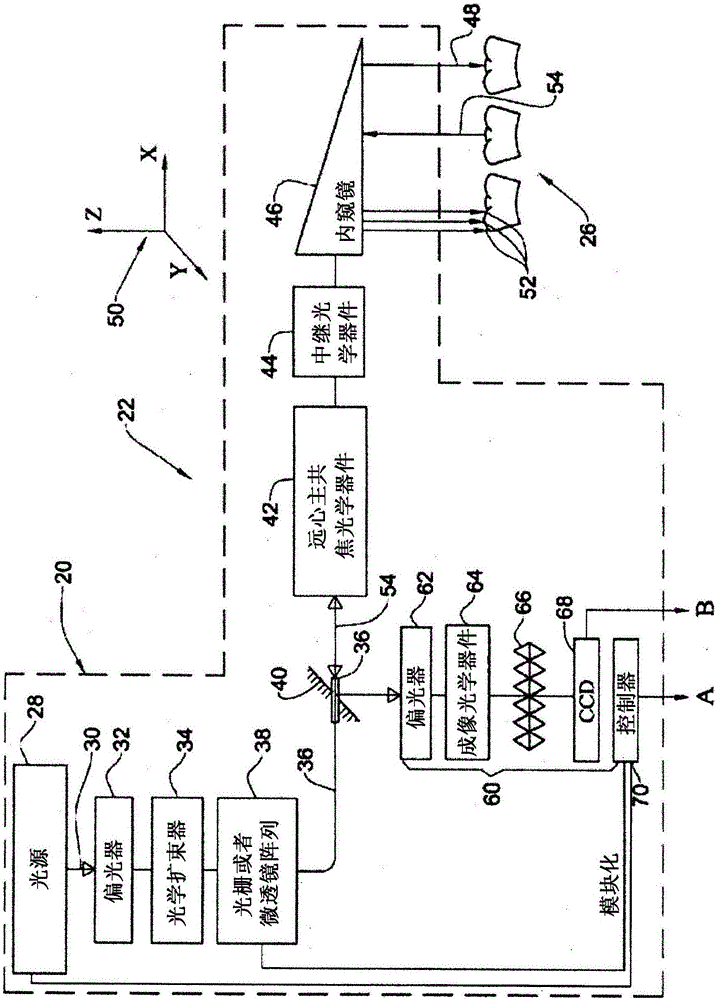

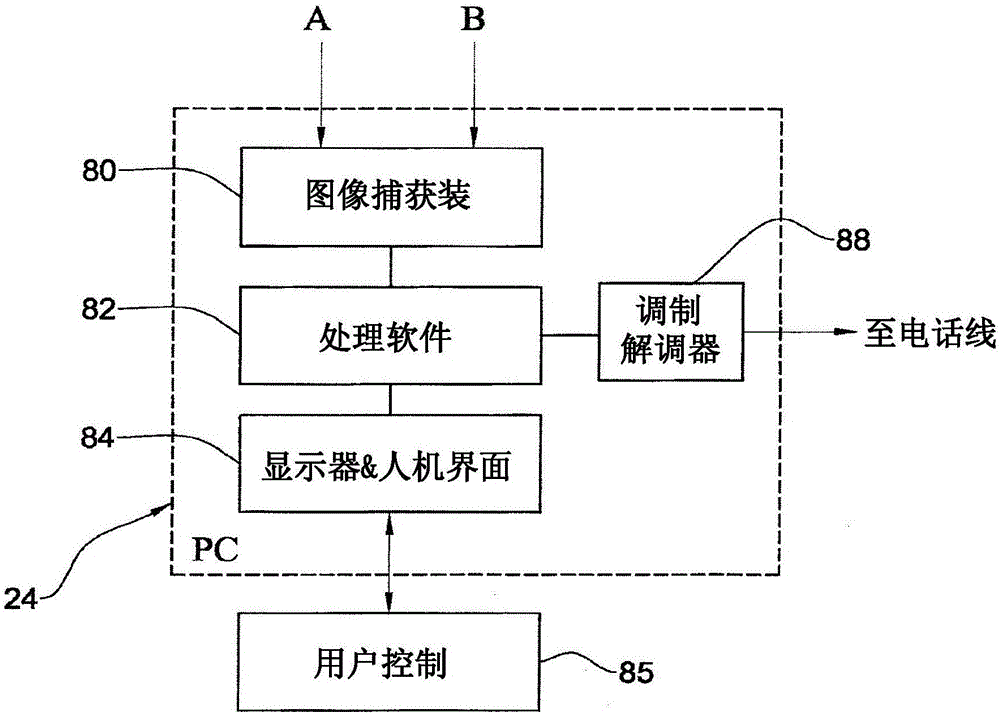

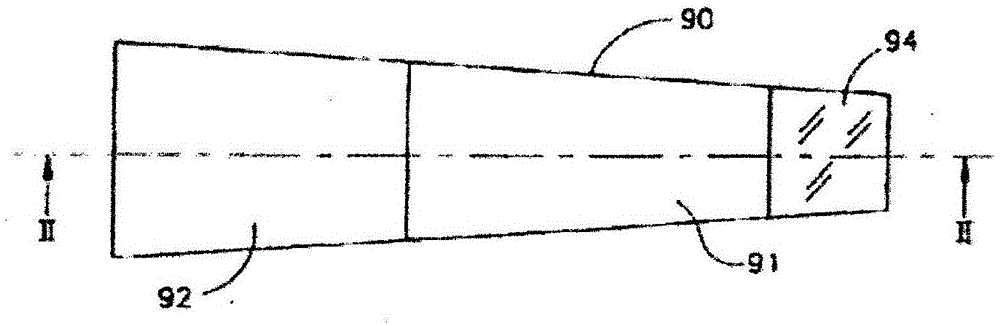

[0021] In various embodiments, the systems and methods described herein for determining the surface topography of a three-dimensional structure focus a two-dimensional array of light beams of multiple wavelengths to multiple focal lengths relative to the optical assembly. The surface topography can be determined by determining the wavelength with the best focus at each point in the two-dimensional field of view. Since each of the multiple wavelengths is focused to its unique focal length, the distance to each point can be inferred. The beam array can be used to simultaneously illuminate the structure being measured throughout the two-dimensional field of view. In various embodiments, the two-dimensional array of light beams projects the two-dimensional array of light spots onto the structure. Throughout the two-dimensional field of view, the light reflected from each spot on the structure can be directed to the two-dimensional detector, which is configured to process the refle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com