High-pressure jet grouting and shallow-layer stirring combination in-situ remediation method for soil and underground water

A high-pressure rotary spraying and in-situ repairing technology, which is applied in the restoration of polluted soil, etc., can solve the problems of tight repair schedule and large differences in the distribution concentration of organic pollutants, so as to eliminate secondary pollution problems, low cost and easy installation. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

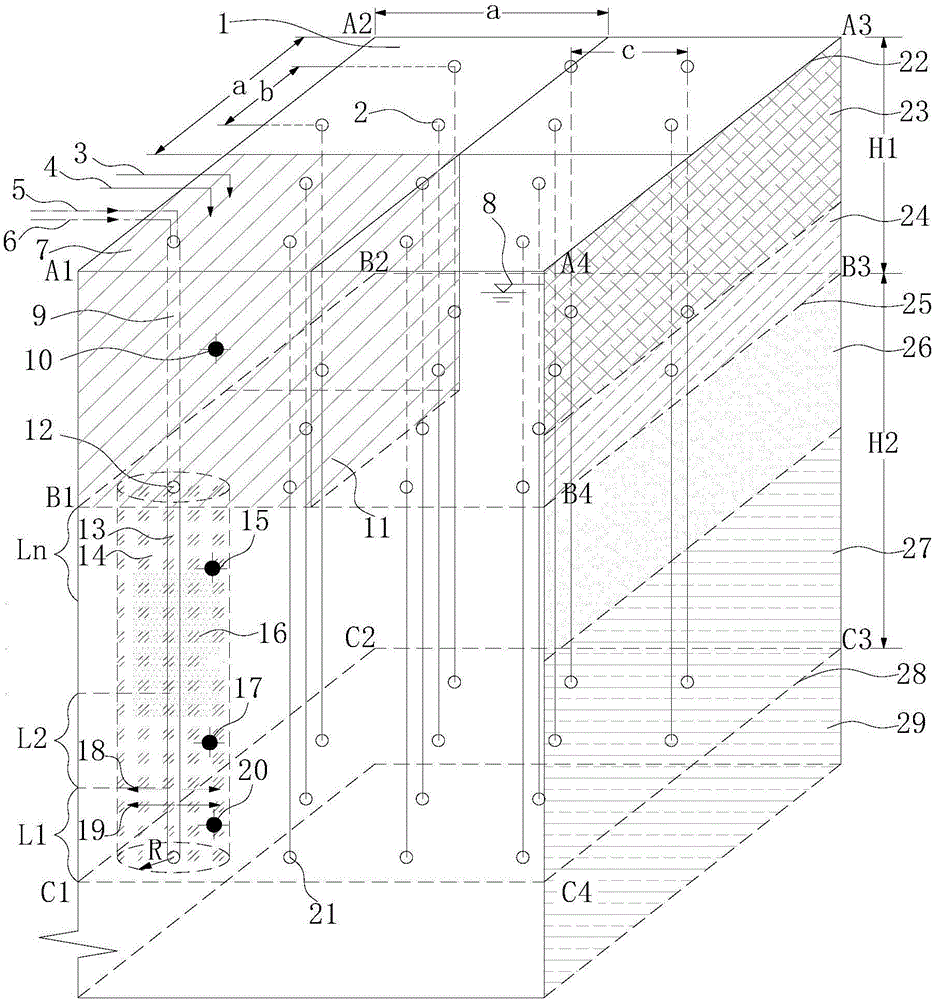

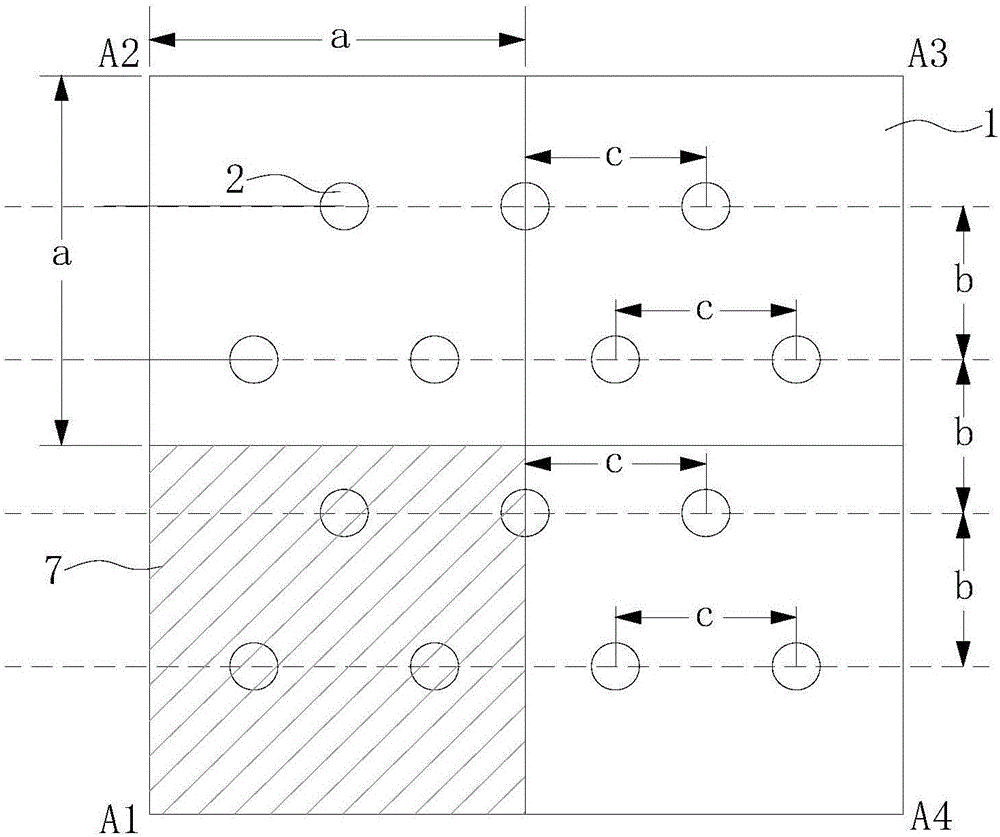

[0102] This example is an in-situ chemical oxidation technology for key polluted land plots / areas in organically polluted soil / groundwater remediation projects. The combined remediation process of deep-layer high-pressure rotary jet injection-shallow layer in-situ stirring is used to realize remediation agents (oxidants K, C) The method of adding, the operation not specifically described in this embodiment, refer to the method already given in the summary of the invention, and will not be repeated here.

[0103] This embodiment is specifically as follows:

[0104] Take the soil and groundwater remediation project of a chemical plant in Nanjing as an example. The soil remediation project volume of the project is 258,000 square meters, and the groundwater remediation project volume is 170,000 square meters. The target pollutants in the soil and groundwater are chlorobenzene, p- / o-nitrochlorobenzene (hereinafter referred to as "p / o nitrate") and other VOCs / SVOCs organic substance...

Embodiment 2

[0106] This example repairs the target pollutants chlorobenzene and p / o-nitrochlorinated benzene (abbreviated as p / o-nitrogen) in Example 1 with high-pressure rotary jet injection and shallow stirring combined in-situ repair method The effect is evaluated.

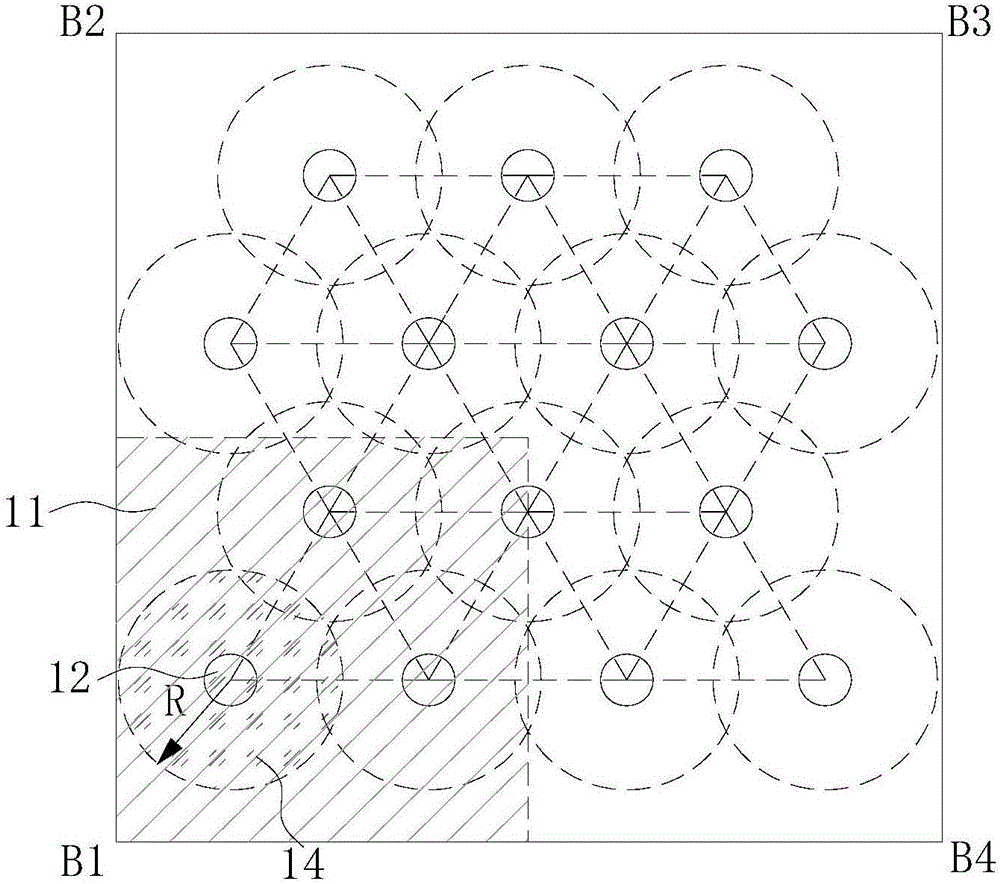

[0107] The repair of the main body adopts a technological plan of injecting a round of K agent. The first round of acceptance found that there are sporadic pollution sources in the local area exceeding the standard. Therefore, the supplementary repair adopts the method of the present invention, that is, the deep layer is 4 to 12m deep using high-pressure rotary jet injection technology, 0 ~4m depth adopts shallow in-situ mixing process. Such as Figure 4 , Figure 5 As shown, there are pollution sources at the local 3m and 9m positions (para / o-nitrate > 1000ppm). After multiple rounds of injection and stirring, the main target pollutants in the soil, chlorobenzene and para / o-nitrate, all reached the standard, and the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com