Modularized skid-mounted 3PE/epoxy powder anti-corrosion pipe production line

An epoxy powder, modular technology, applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems of anti-corrosion pipe anti-corrosion quality decline, pipeline service life reduction, increase pipeline maintenance costs, etc., to achieve fast and convenient installation, The effect of saving investment and quick on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

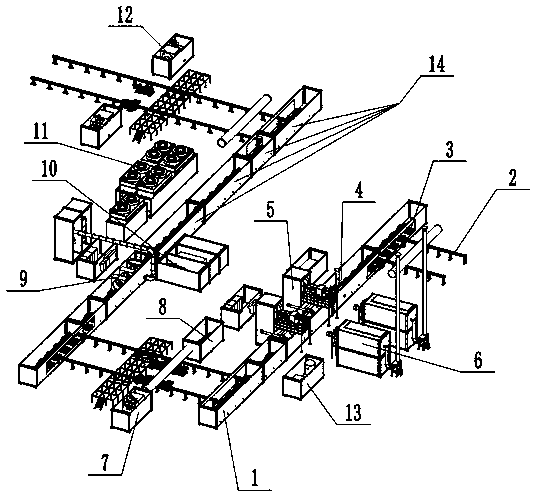

[0012] see Figure 1-Figure 2 As shown, the technical scheme adopted in this specific embodiment is: it consists of the first helical drive line module 1, the pipe inlet platform module 2, the second helical drive line module 3, the flame preheating furnace module 4, and the steel pipe outer wall shot blasting. Rust machine module 5, dust collector module 6, pipe purge trolley module 7, pipe purge dust recovery trolley module 8, intermediate frequency heating module 9, spray extruder module 10, cooling module 11, pipe end treatment module 12, electric control Module 13 and water cooling treatment module 14 are composed of the first helical transmission line module 1 connected to the tube-intake platform module 2, the structure of the first helical transmission line module 1 and the second helical transmission line module 2 are consistent, the first helical transmission line module 1 The module 1, the second spiral transmission line module 3 and the pipe inlet frame module 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com