Construction method of wiener plate light composite grouting wall system

A wall and lightweight technology, applied to walls, building components, climate change adaptation, etc., can solve the problems of unsatisfactory green buildings, complicated construction technology, high cost, etc., and achieve good economic and social benefits, advanced technology, Reliable effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

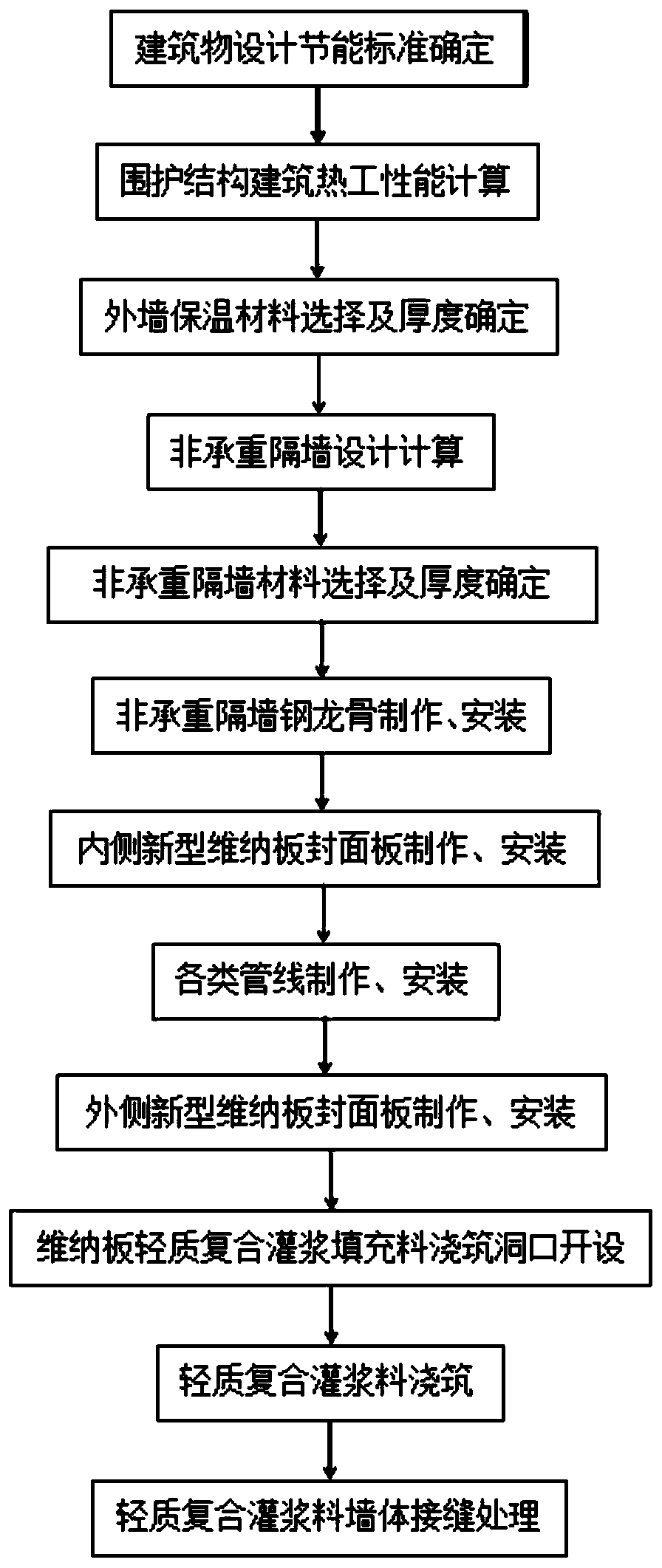

[0028] This embodiment provides a construction method of a Wiener board lightweight composite grouting wall system, such as figure 1 As shown, first determine the energy-saving standards for building design, thermal performance of building envelopes, and the selection and thickness of external wall insulation materials through calculation; determine the design of non-load-bearing walls and the selection of non-load-bearing partition wall materials and thickness determination through calculation. Then carry out the following procedures.

[0029] Steel keel keel installation

[0030] 1. Cut the keel with scissors and hacksaw, and install the keel along the top and the ground on the concrete wall with air gun nails. The distance between the nails should not exceed 600mm, and the distance between the installation of the C-shaped keel is 407mm.

[0031] 2. In order to meet the special height of the wall, some keels need to be extended. The overlapping part of the extended keel sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com