A friction wheel separation device and separation method using bionic materials

A technology of bionic materials and separation devices, applied in pile separation, thin material processing, object separation, etc., can solve the problems of high cost, one-time separation of multiple layers of cloth, complex structure, etc., and achieve low cost, stable up and down, and improved The effect of the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

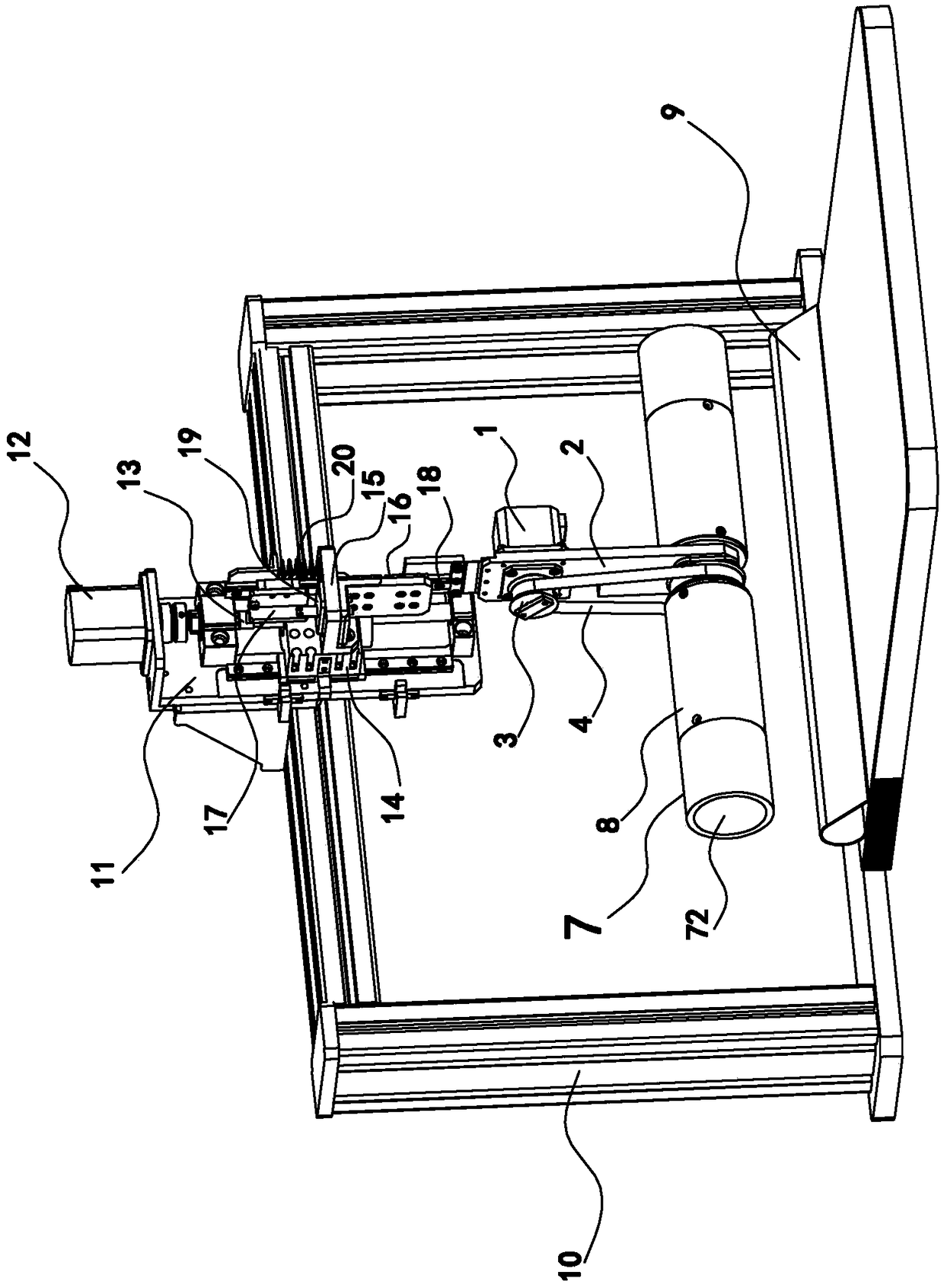

[0031] Embodiment of friction wheel separation device

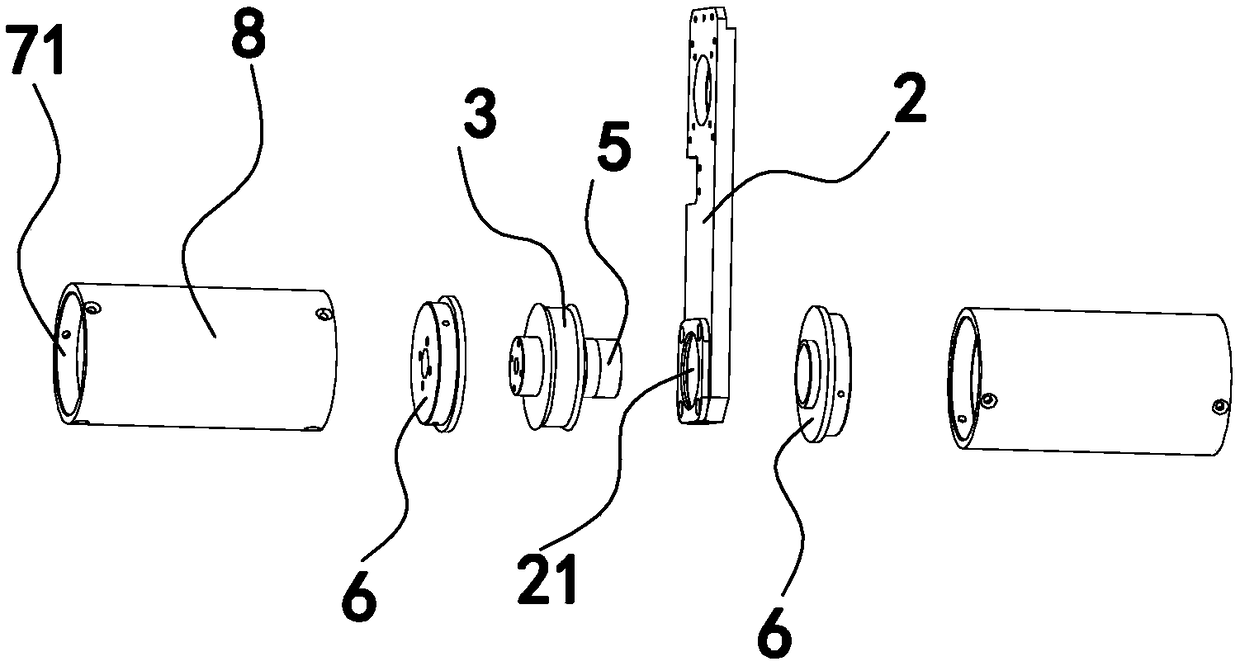

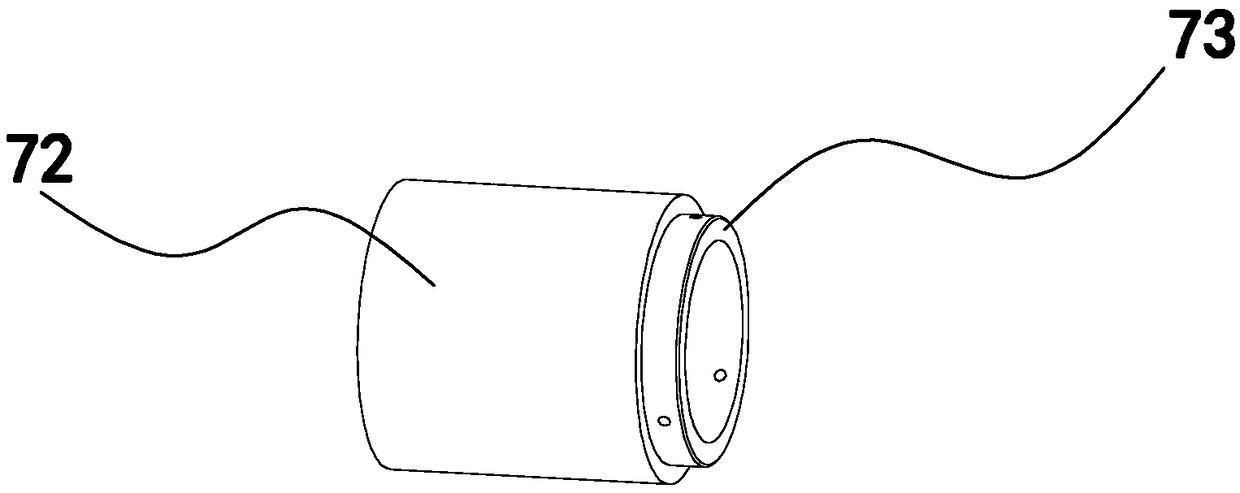

[0032] Such as figure 1 As shown, the friction wheel separation device using bionic materials includes a support connecting plate 2, a friction wheel 7, a controller, a lifting mechanism connected with the controller, and a detection device. Of course, it is conceivable that it also includes some other equipment structures, such as man-machine exchange interface, which is used to input pressure setting value parameters, that is, pre-pressure, which determines different pre-pressure values according to different types of separating cloth 9; For example, the frame 10 used to support the entire separation device, these equipment structures are all prior art in this technica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com