A kind of sintered casting magnesium aluminum zirconium chromium sliding plate and preparation method thereof

A sliding plate and chrome technology, which is applied in the field of refractory materials, can solve the problems of poor erosion resistance and corrosion resistance, and achieve the effects of good adaptability, increased strength, and improved thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

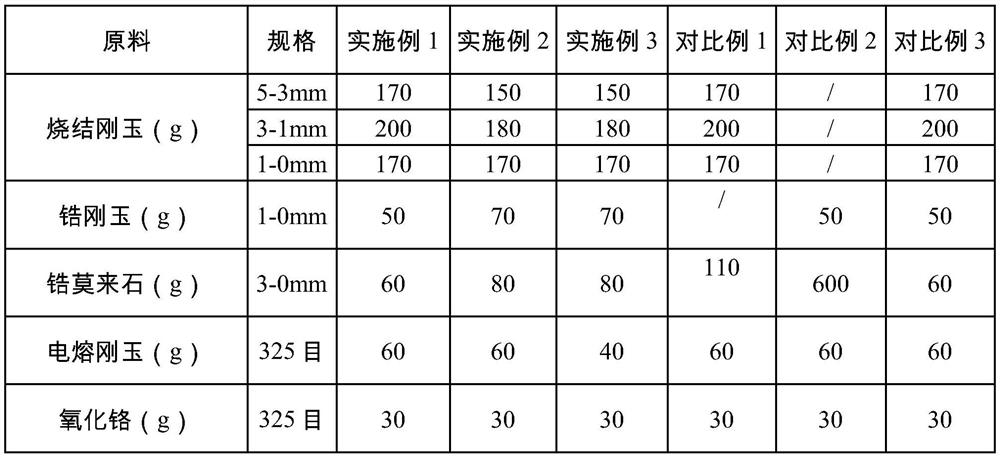

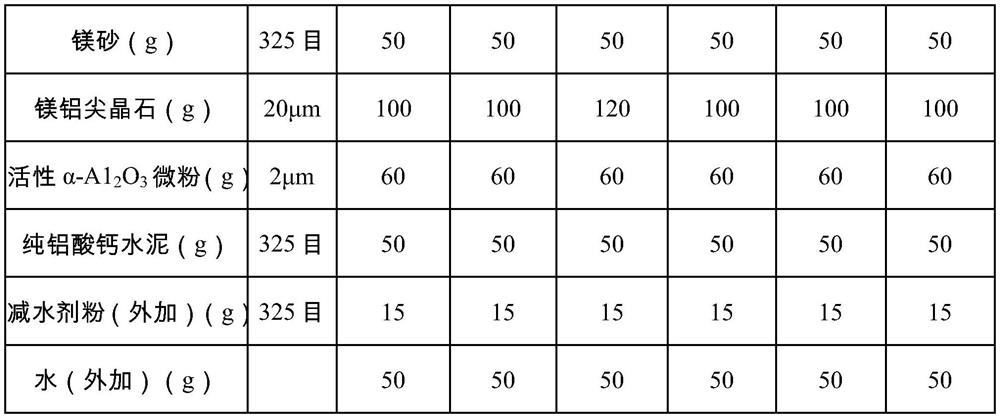

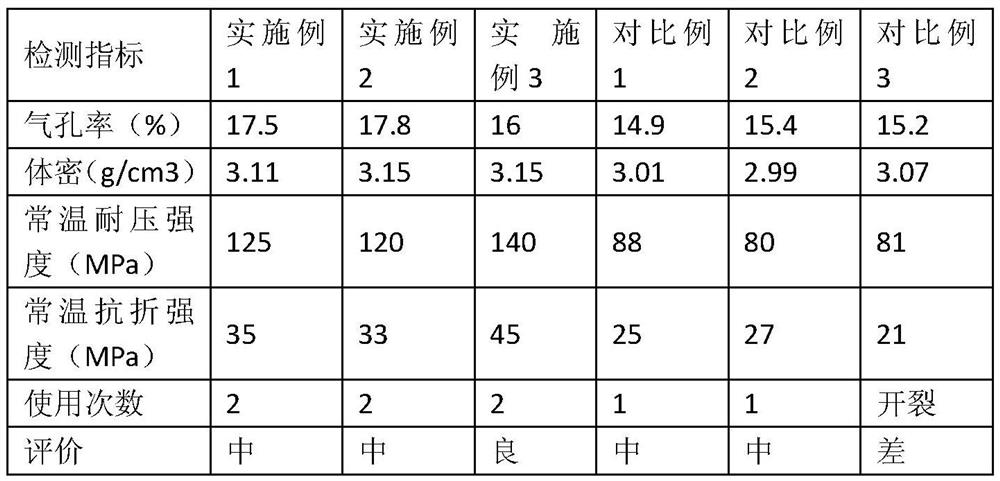

Examples

Embodiment

[0036] This embodiment provides a sintered and cast magnesia-aluminum-zirconium-chromium sliding plate and a preparation method thereof. The preparation method includes the following steps: weighing fused corundum, chromium oxide, magnesia, magnesia-aluminum spinel, α-alumina Micropowder, calcium aluminate cement and water reducing agent are added to the forced mixer and mixed for 5 minutes, add water, after mixing evenly, add sintered corundum, zirconium corundum, zirconium mullite, mix for 3 minutes, add water, mix well, pour into the mold After 12 hours, the temperature in the drying kiln was raised from room temperature to 100°C at a constant rate, kept for 8 hours, and then the temperature in the drying kiln was raised to 20 hours after 12 hours. 200℃, heat preservation for 15h; finally, the temperature in the drying kiln was raised to 1550℃ after 40h, maintained for 15h, and then cooled to room temperature naturally. By heating the steel hoop, the steel hoop is put on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com