Synthesizing technology of water dispersant type polyaminoester emulsion

A technology of polyurethane emulsion and synthesis process, which is applied in the field of synthesis process of water-dispersed polyurethane emulsion, which can solve the problems of yellowing, tensile strength, stickiness, etc., and achieve the effects of film formation, easy drying, reduced energy consumption, and no special smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

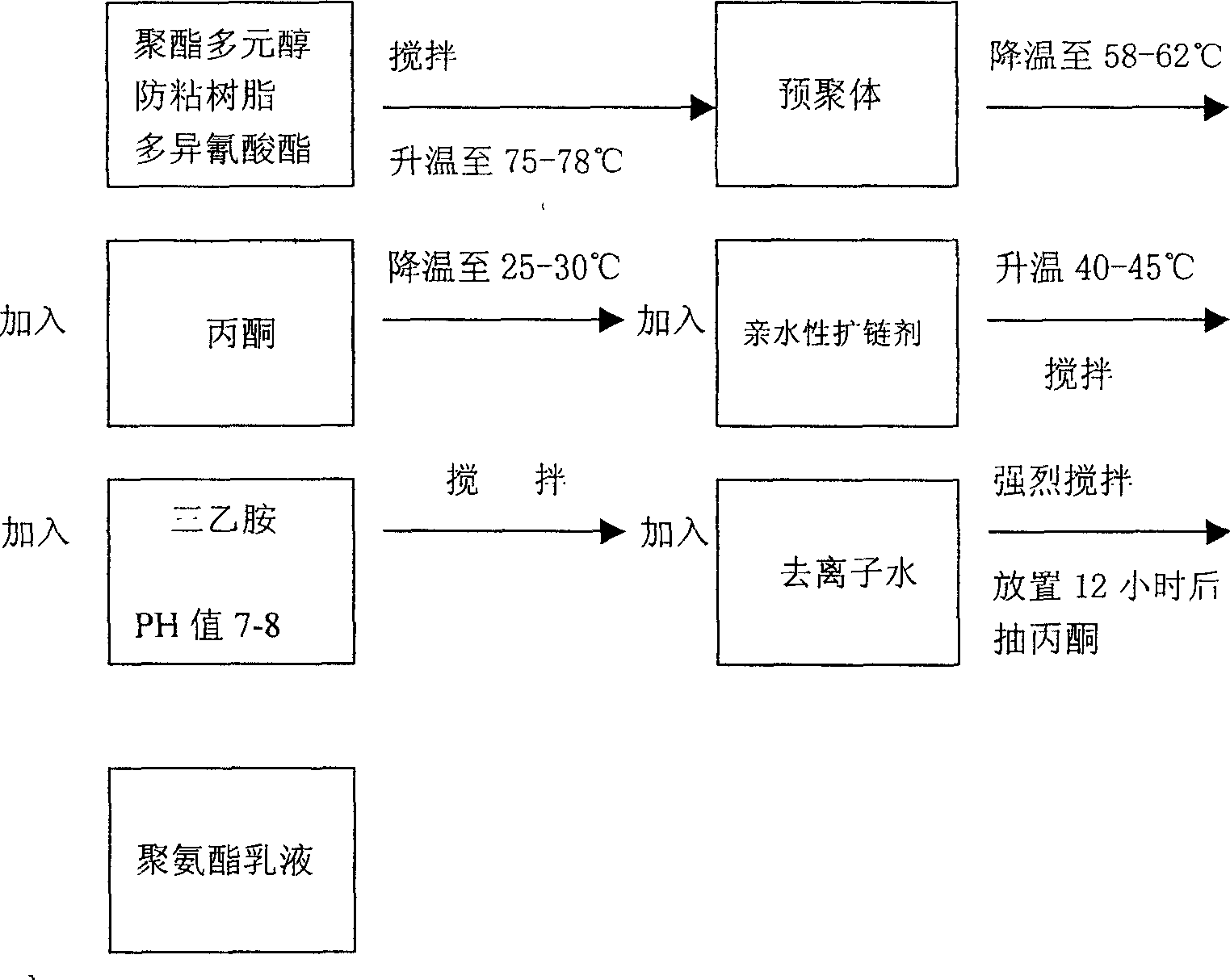

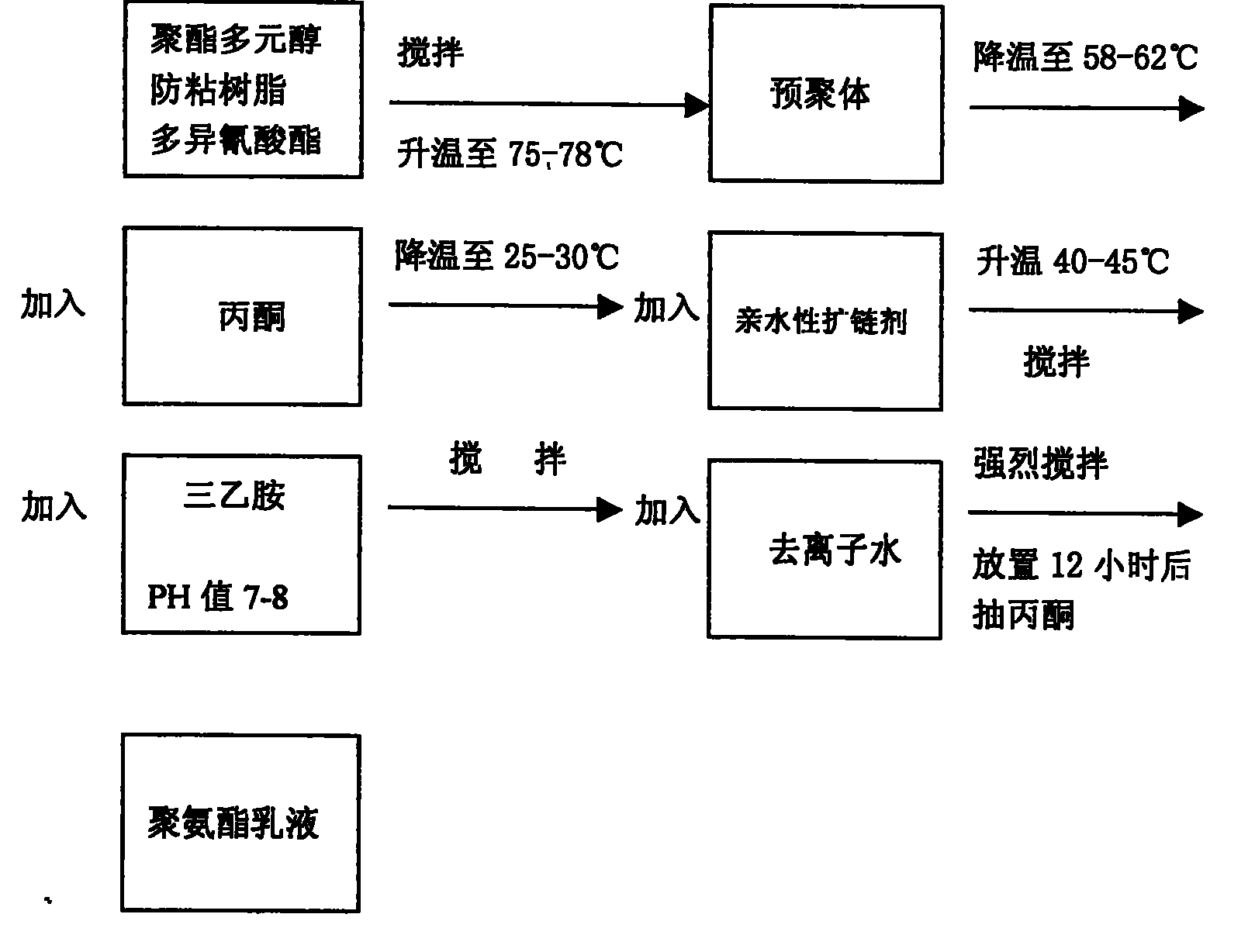

Method used

Image

Examples

Embodiment 1

[0027] Add 100 parts by weight of polyol, 10 parts by weight of anti-adhesive resin, and 37 parts of polyisocyanate into the reaction kettle, stir evenly and heat up to 75-78°C, continue stirring for 2 hours to form a prepolymer; cool down to 60°C , add the solvent acetone that is 83 parts by weight, make its viscosity reduce;

[0028] Cool down to 25-30°C, add 10 parts by weight of dimethylol propionic acid; raise the temperature to 40-45°C, neutralize to pH 7-8 with 7 parts by weight of triethylamine after 30 minutes;

[0029] Add the deionized water that is 53 parts by weight, emulsify for 1 hour;

[0030] After standing for 12 hours, raise the temperature of the emulsion to 60°C, remove the acetone, add a small amount of RM-2020 leveling agent, DSX2000, such as 815M defoamer to the emulsion, and compound the polyurethane emulsion.

Embodiment 2

[0032] Add 100 parts by weight of polyol, 8 parts by weight of anti-adhesive resin, and 39 parts of polyisocyanate into the reaction kettle, stir evenly and then raise the temperature to 75-78°C, continue stirring for 1.5 hours to form a prepolymer; cool down to 58°C , add the solvent acetone that is 80 parts by weight, make its viscosity reduce;

[0033] Cool down to 25-30°C, add 12 parts by weight of dimethylolpropionic acid; raise the temperature to 40-45°C, neutralize to pH 7-8 with 8 parts by weight of triethylamine after 25 minutes;

[0034] Add the deionized water that is 50 parts by weight, emulsify for 50 minutes;

[0035] After standing for 14 hours, raise the temperature of the emulsion to 60°C, remove the acetone, add a small amount of RM-2020 leveling agent, DSX2000, such as 815M defoamer to the emulsion, and compound the polyurethane emulsion.

Embodiment 3

[0037] Add 100 parts by weight of polyol, 12 parts by weight of anti-adhesive resin, and 35 parts of polyisocyanate into the reaction kettle, stir evenly and then raise the temperature to 75-78°C, continue stirring for 2 hours to form a prepolymer; cool down to 62°C , add the solvent acetone that is 85 parts by weight, make its viscosity reduce;

[0038] Cool down to 25-30°C, add 8 parts by weight of dimethylolpropionic acid; raise the temperature to 40-45°C, neutralize to pH 7-8 with 6 parts by weight of triethylamine after 35 minutes;

[0039] Add the deionized water that is 55 parts by weight, emulsify for 1 hour;

[0040] After standing for 13 hours, raise the temperature of the emulsion to 60°C, remove the acetone, add a small amount of RM-2020 leveling agent, DSX2000, such as 815M defoamer to the emulsion, and compound the polyurethane emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com