Riverway floating object recovery and treatment method

A technology for recycling and disposing of floating objects, which is applied to the cleaning of open water surfaces, water conservancy projects, construction, etc., to solve problems such as the inability to salvage floating objects, increase the workload of cleaning machines, and increase the intensity of manual work, so as to avoid sudden The effect of dropping, increasing the cleaning range, and increasing the number of grabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

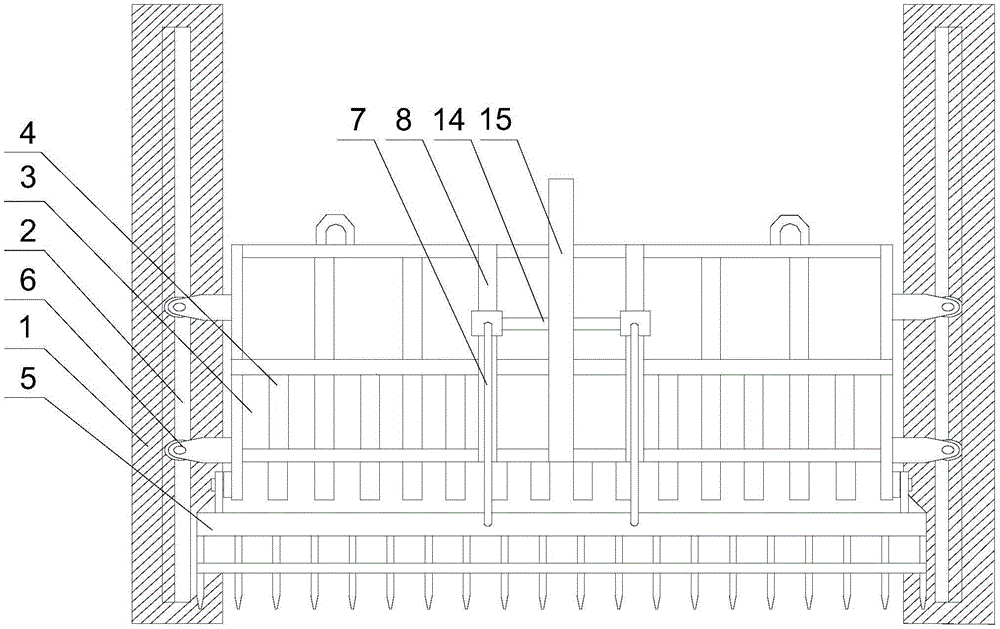

[0026] Such as figure 1 and figure 2 Shown, the present invention comprises the following steps:

[0027] A Start the hydraulic cylinder, and the jacking rod drives the support column to move forward under the push of the output end of the hydraulic cylinder to expand the cleaning range;

[0028] The B fence body moves up and down quickly in the groove of the guide rail under the traction of the connecting rod. Manually adjust the screw rod, which cooperates with the threaded through hole, so that the moving block moves on the connecting rod, and the moving block is driven by the connecting rod. The lower rake claws are opened, and the fence body moves down into the water;

[0029] C. The upper claw blocks the floating object to prevent it from moving further, and reversely rotates the screw rod, so that the lower claw automatically moves down, and cooperates with the upper claw to clamp the floating object. Finally, under the traction of the connecting rod, the fence body ...

Embodiment 2

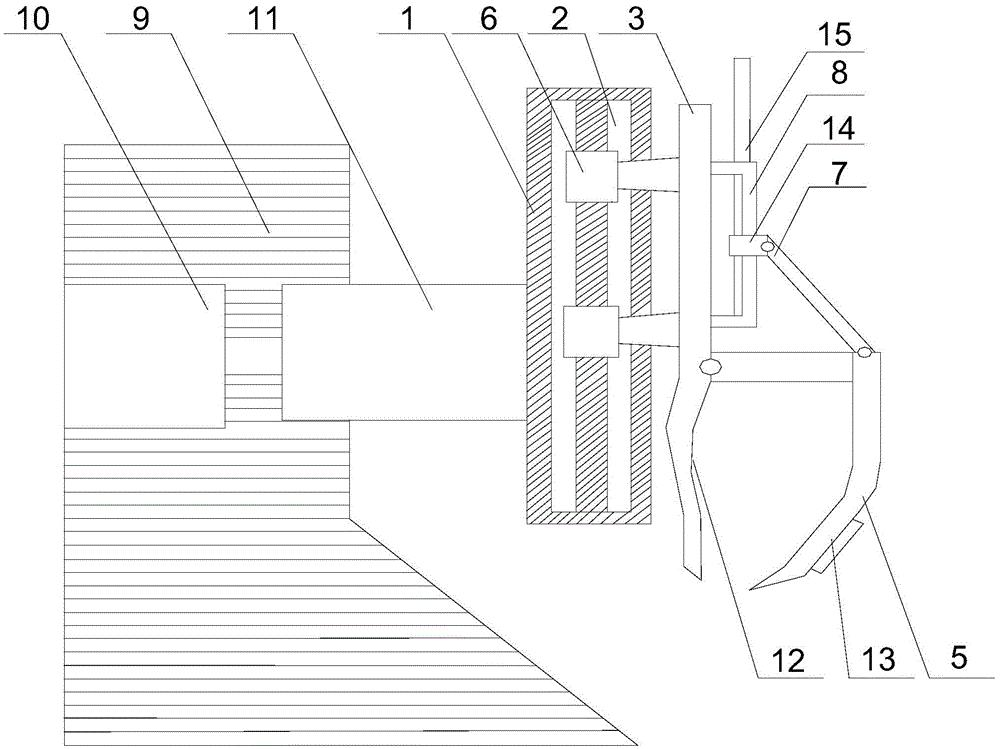

[0032] Such as figure 2 As shown, this embodiment is based on Embodiment 1. The upper claw 4 is provided with a detour 12 whose bending direction is opposite to that of the lower claw 5 , and the detour 12 is located below the fence body 3 . The detour 12 on the upper claw 4 can increase the inner area of the annular clamping space formed by the upper claw 4 and the lower claw 5. When the upper claw 4 penetrates into the water surface, the floating object will be blocked to prevent it from continuing to move. The claw 5 clamps the floating objects under the action of its own gravity, and while preventing the floating objects from falling off each time it is grabbed, it can also greatly increase the number of grabs and improve the collection efficiency.

Embodiment 3

[0034] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and a counterweight 13 is installed at the end of the lower claw 5 . When the number of grabs is large or the volume of the floating object itself is large, and the gravity effect of the lower claw 5 itself is not enough to hold the floating object stably, the counterweight 13 arranged at the end of the lower claw 5 can indirectly increase the weight of the lower claw 5. The clamping strength of the rake claws 5 on the floating objects, and the lower rake claws 5 are hingedly connected with the fence body 3. Under the action of manual adjustment of the steel rope, the grabbing efficiency can be ensured each time, and at the same time, the captured floating objects can be prevented from falling on the fence body 3. Falling suddenly while rising.

[0035] Further, preferably, the angle at which the lower claws 5 move up and down is 0° to 110°. The movable angle of the lower rake claw 5 is set in the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com