Rotary sectional steel casing

A steel casing, segmented technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of little use value and large deformation of steel casing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

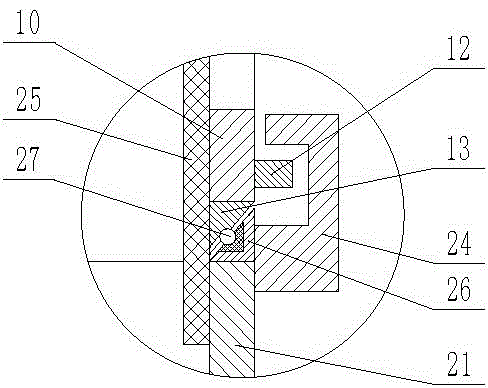

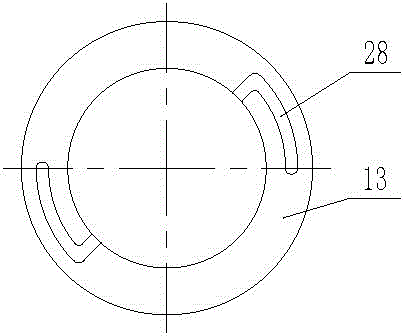

[0018] The reference signs in the drawings of the specification include: explosion-proof steel casing section 10, water inlet hole 11, arc connecting plate 12, lower annular cone 13, standard steel casing section group 20, upper standard steel casing section 21, Middle standard steel casing section 22, lower standard steel casing section 23, arc seat 24, elastic plate 25, upper annular cone 26, steel ball 27, guide groove 28.

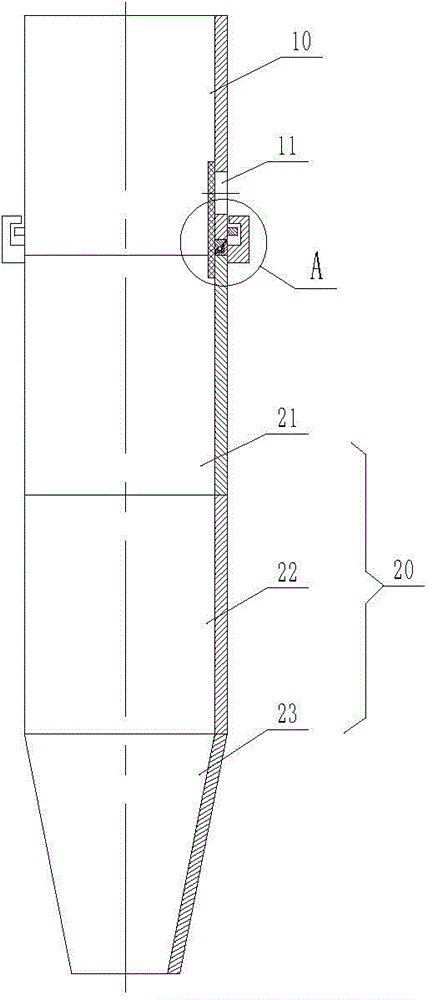

[0019] The embodiment is basically as figure 1 : Rotating segmented steel casing, from top to bottom: explosion-proof steel casing section 10 and standard steel casing section group 20, of which standard steel casing section group 20, from top to bottom is the upper standard welded to each other Steel casing section 21, medium standard steel casing section 22 and lower standard steel casing section 23, and lower standard steel casing section 23 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com