Hydraulically driven coalbed methane well drainage and production tubular pump

A technology for coalbed methane wells and tubular pumps, which is applied to variable-capacity pump components, liquid variable-capacity machinery, and liquid fuel engines, etc., can solve problems such as shortening the pump inspection period, eccentric wear of sucker rods, etc., and achieves convenient parameter adjustment. , The effect of solving the eccentric wear of the rod and reducing the pressure loss along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

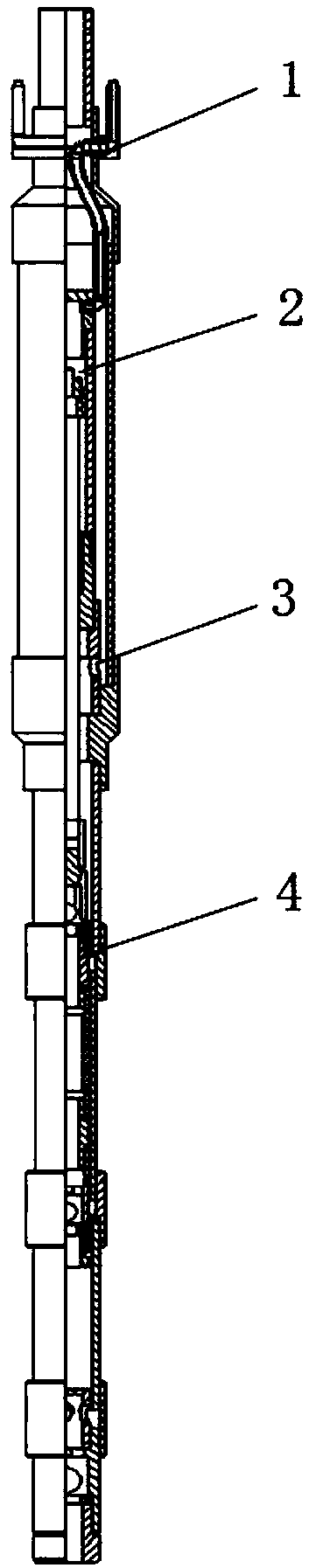

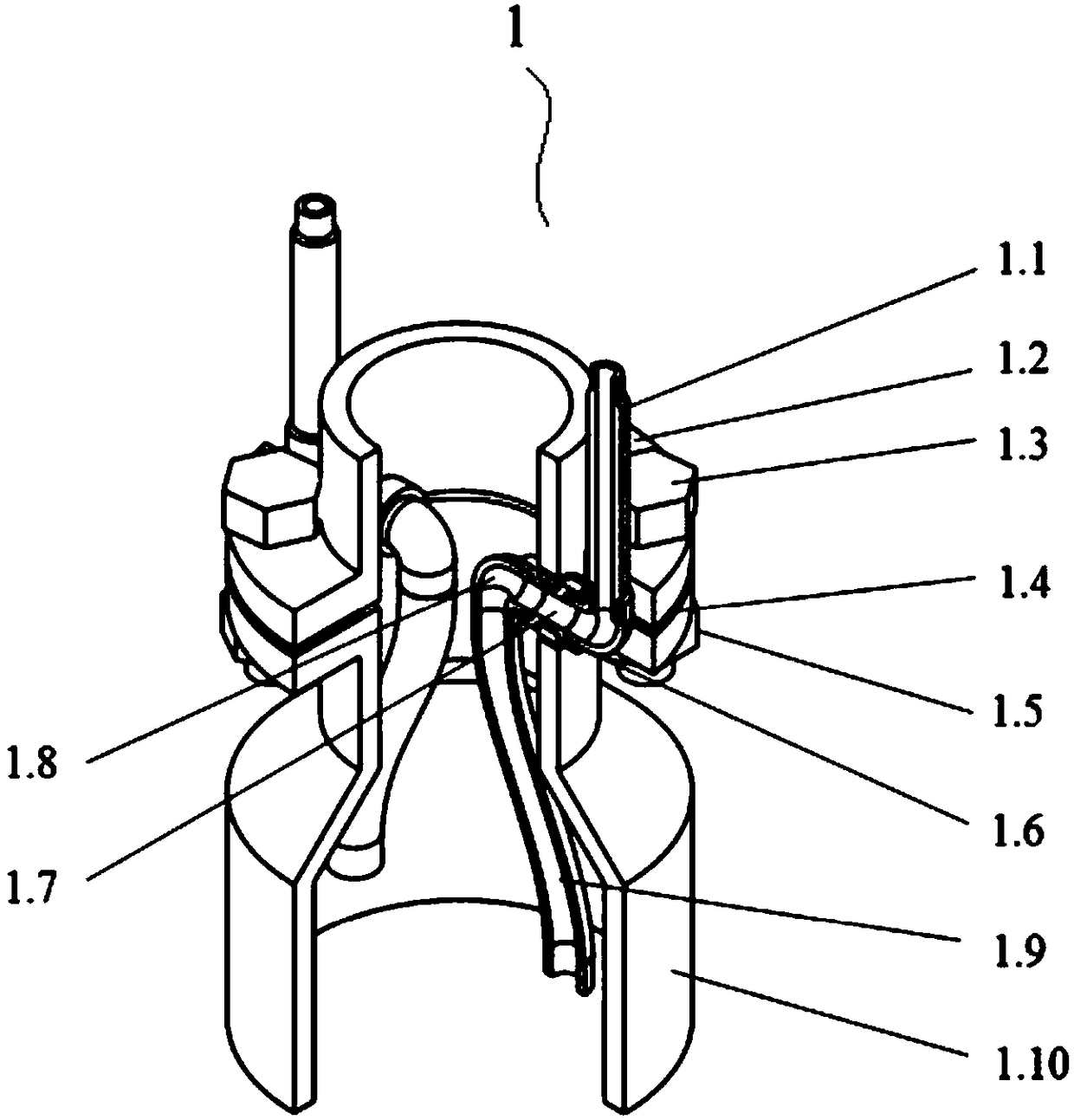

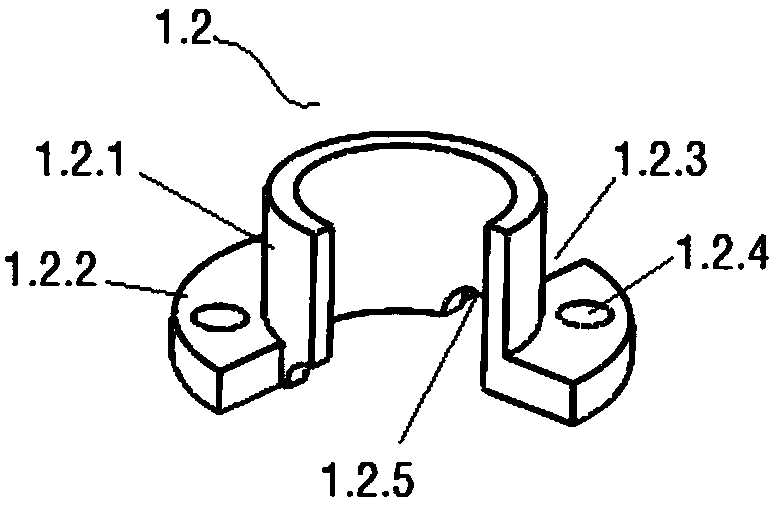

[0035] Such as figure 1 , Figure 5As shown, a hydraulically driven coalbed methane well drainage tubular pump provided by the present invention includes a variable-diameter flange joint part 1, a power cylinder part 2, a power cylinder plunger pump joint part 3 and a column connected in sequence from top to bottom. The plug pump part 4, wherein the power cylinder part 2 includes the rodless chamber power pipeline 2.1, the rod chamber power pipeline 2.2, the cylinder bottom 2.3, the power cylinder inner cylinder 2.4, the piston 2.6, the piston rod 2.7, the guide sleeve 2.8 and the power cylinder outer cylinder 2.9, wherein the upper end of the power cylinder outer cylinder 2.9 is threadedly connected to the variable diameter flange jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com