Continuous micro-line segment look-ahead control interpolation algorithm

An interpolation algorithm and line segment technology, which is applied in the field of forward control interpolation algorithms for continuous tiny line segments, can solve problems such as speed fluctuations and acceleration sudden changes, and achieve the effects of smooth motion, reduced impact, and reduced errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

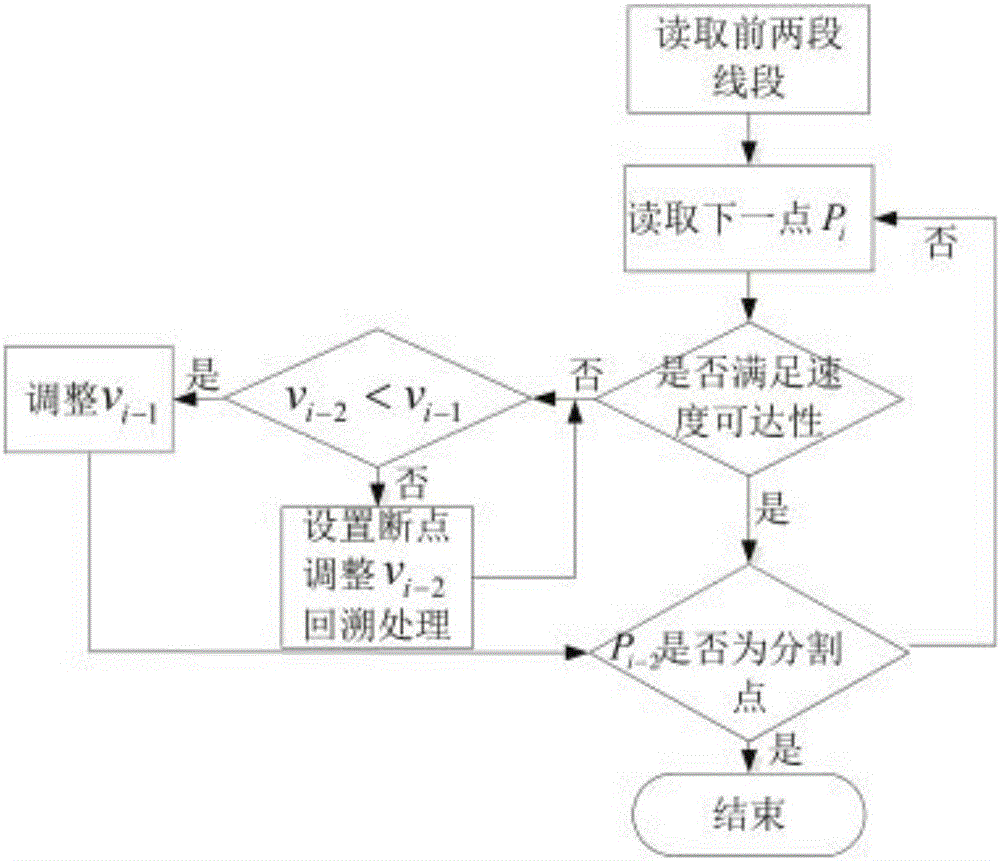

[0017] see figure 1 , this embodiment shows a forward-looking control interpolation algorithm for continuous tiny line segments:

[0018] Including the following steps:

[0019] 1) Sequentially read the three endpoints P1, P2 and P3 of the first two tiny line segments, and set the initial speed of the line segment v1=0, since there is no transition angle at the beginning of the line segment, α1 =0, the local transition distance of P1 point Δl1 = 0; use the cosine formula to calculate the transfer angle α2 at P2, solve the theoretical maximum feed speed v2 at P2 according to the calculation formula of the angle bisector transfer algorithm, and calculate the local transfer distance Δl2 at P2; calculate the distance from P1 to P2 The distance L2 from L1 and P2 to P3, and then calculate the actual interpolation distance s1 of the first small line segment using the actual interpolation distance formula in the solution of the maximum transfer speed, s1=L1-Δl1-Δl2;

[0020] 2) Read...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com