High-protein milk and production method thereof

A high-protein, milk technology, applied in the field of high-protein milk production, can solve problems such as bad taste, increased liquid viscosity, and heavy taste of protein powder, etc., to achieve smooth and delicate taste, low fat content, and fresh taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

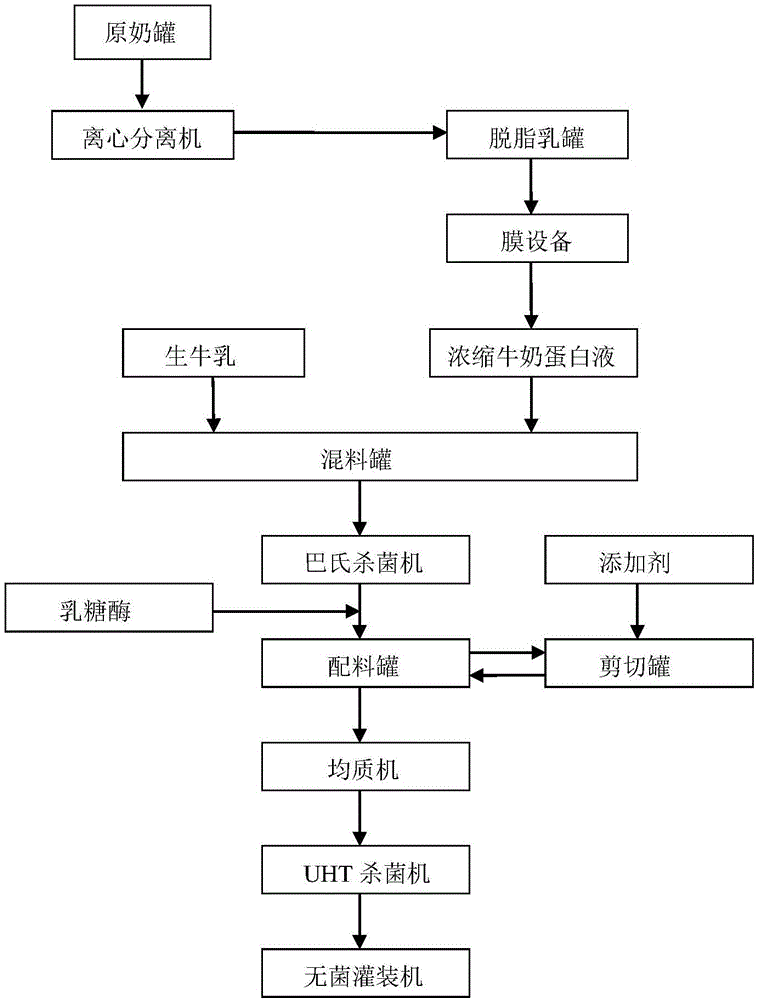

[0020] A method for producing high-protein milk, specifically comprising the steps of:

[0021] (1) Preparation of raw materials: Preheat and centrifuge part of the raw milk in the raw milk tank to obtain standardized cream and skim milk, temporarily store the skim milk in the skim milk tank, and then filter the skim milk through membrane equipment to obtain concentration Milk protein liquid, and then store another part of raw milk and concentrated milk protein liquid in different storage tanks as the main raw materials for use, and take samples to test the indicators of each material. Among them, the protein content of raw milk is 3.0%, and the fat content It is 3.6%, the detection process conforms to GB 19302, the protein content of concentrated milk protein liquid is 14.5%, and the fat content is 0.3%, the detection process conforms to the enterprise standard Q / NXSS0006S-2016;

[0022] (2) Proportion calculation: Calculate the addition amount of each material according to t...

Embodiment 2

[0034] A method for producing high-protein milk, specifically comprising the steps of:

[0035] (1) Preparation of raw materials: Preheat and centrifuge part of the raw milk in the raw milk tank to obtain standardized cream and skim milk, temporarily store the skim milk in the skim milk tank, and then filter the skim milk through membrane equipment to obtain concentration Milk protein liquid, and then store another part of raw milk and concentrated milk protein liquid in different storage tanks as the main raw materials for use, and take samples to test the indicators of each material. Among them, the protein content of raw milk is 3.0%, and the fat content It is 3.6%, the detection process conforms to GB 19302, the protein content of concentrated milk protein liquid is 14.5%, and the fat content is 0.3%, the detection process conforms to the enterprise standard Q / NXSS0006S-2016;

[0036] (2) Proportion calculation: Calculate the addition amount of each material according to t...

Embodiment 3

[0048] A method for producing high-protein milk, specifically comprising the steps of:

[0049] (1) Preparation of raw materials: Preheat and centrifuge part of the raw milk in the raw milk tank to obtain standardized cream and skim milk, temporarily store the skim milk in the skim milk tank, and then filter the skim milk through membrane equipment to obtain concentration Milk protein liquid, and then store another part of raw milk and concentrated milk protein liquid in different storage tanks as the main raw materials for use, and take samples to test the indicators of each material. Among them, the protein content of raw milk is 3.2%, and the fat content The detection process complies with GB 19302. The protein content of the concentrated milk protein liquid is 13.5%, and the fat content is 0.2%. The detection process complies with the enterprise standard Q / NXSS0006S-2016;

[0050] (2) Proportion calculation: Calculate the addition amount of each material according to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com