Tea leaf drying machine

A technology of a tea dryer and a machine base, which is applied in the field of tea, can solve the problems of reduced energy consumption, low production and use costs, and high production and use costs, and achieve the effects of reducing energy consumption and production and use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

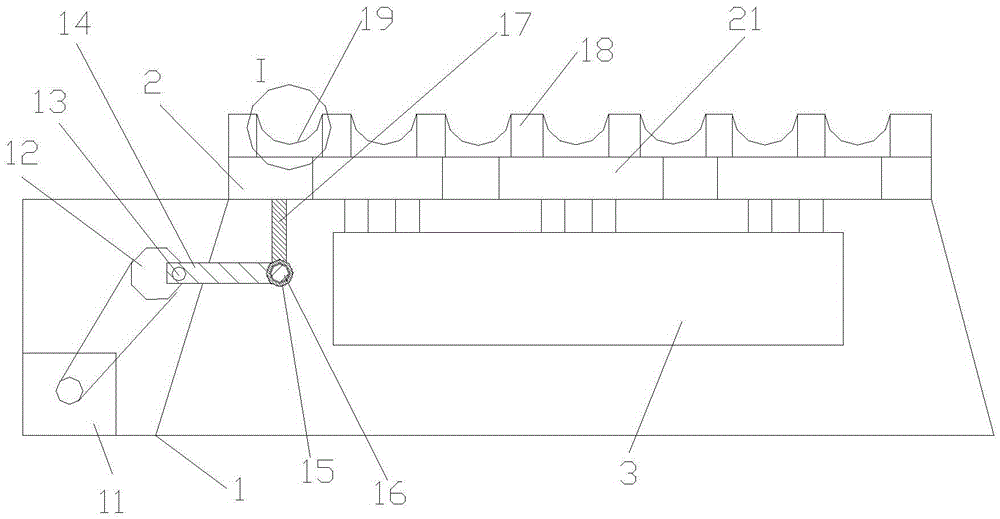

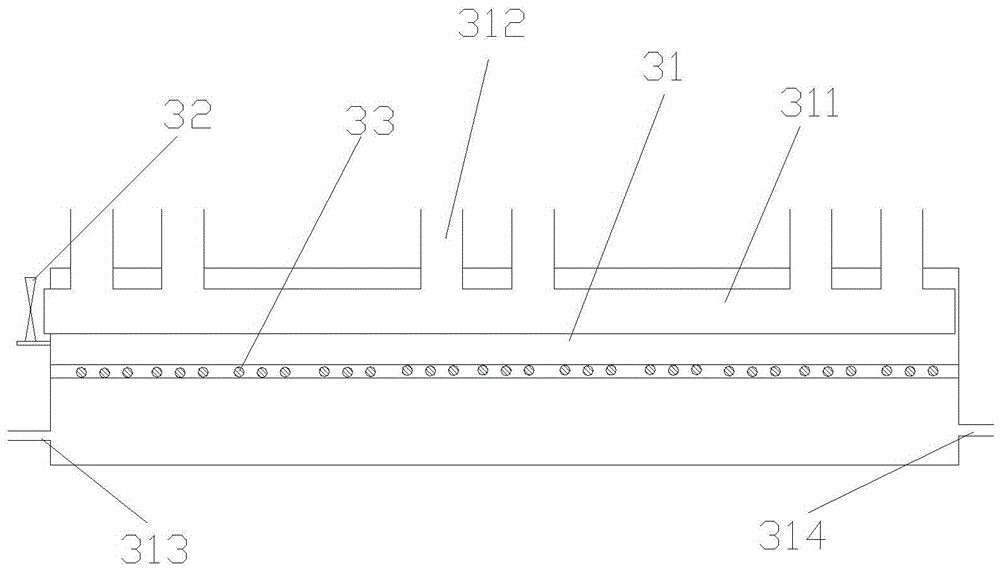

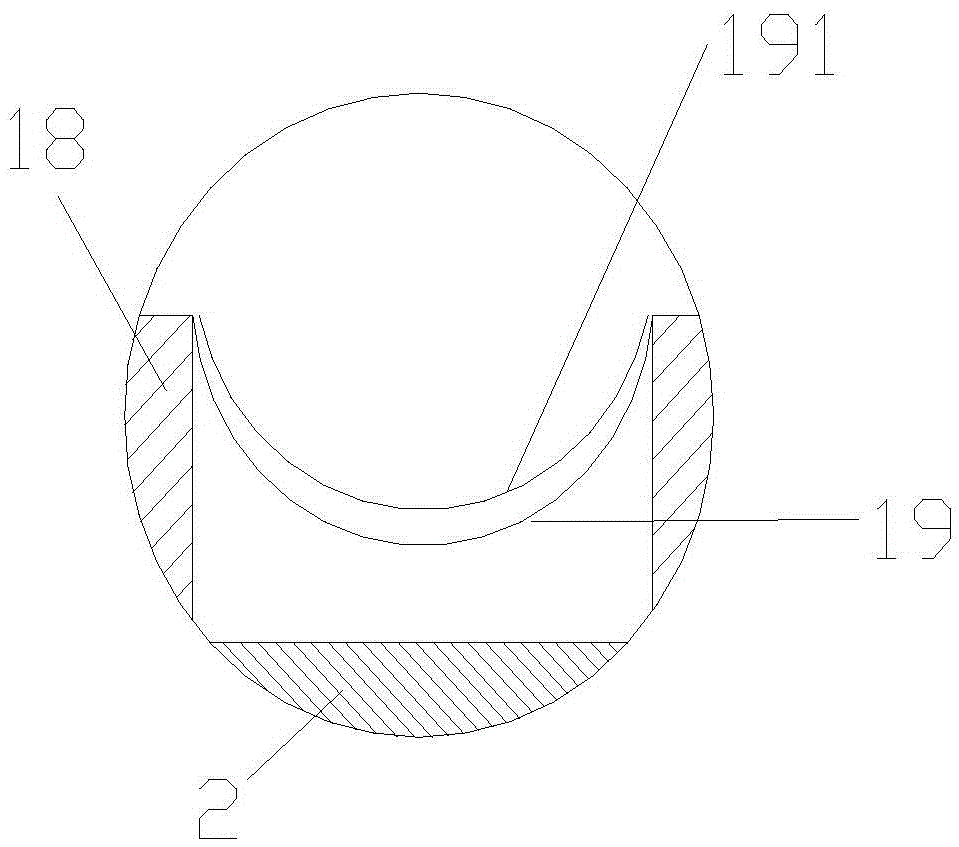

[0015] Such as figure 1 , figure 2 , image 3 As shown, a tea dryer includes a machine base 1. A base 2 is arranged on the machine base 1. The base 2 can swing left and right on the machine base 1. Several through holes 21 are arranged on the base 2. The bottom of the base 2 is provided with There is a biomass fuel heating device 3, the base 1 is provided with a motor 11 and a turntable 12, the motor 11 is connected to the turntable 12 by a belt, and the edge of the turntable 12 is provided with a circular shaft 13 parallel to the axial direction of the turntable 12. A round rod 14 perpendicular to the round shaft 13 is sleeved, a bearing 15 is arranged at the end of the round rod 14, a straight rod 16 parallel to the round shaft 13 is arranged inside the bearing 15, and a connecting rod connected to the base 2 is arranged at the end of the straight rod 16 The rod 17 is provided with several ribs 18 on the base 1, and a baffle 19 is arranged between every two adjacent ribs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com