A vascular implant with superhydrophobic and oleophobic composite nanocoating

A nano-coating, super-hydrophobic technology, applied in the field of medical devices, can solve the problems of low compressive strength, difficulty, and increase patient pain, and achieve the effect of increasing compressive and flexural strength, reducing contact area, and saving hospitalization costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Deep vein catheter with superhydrophobic and oleophobic composite nanocoating

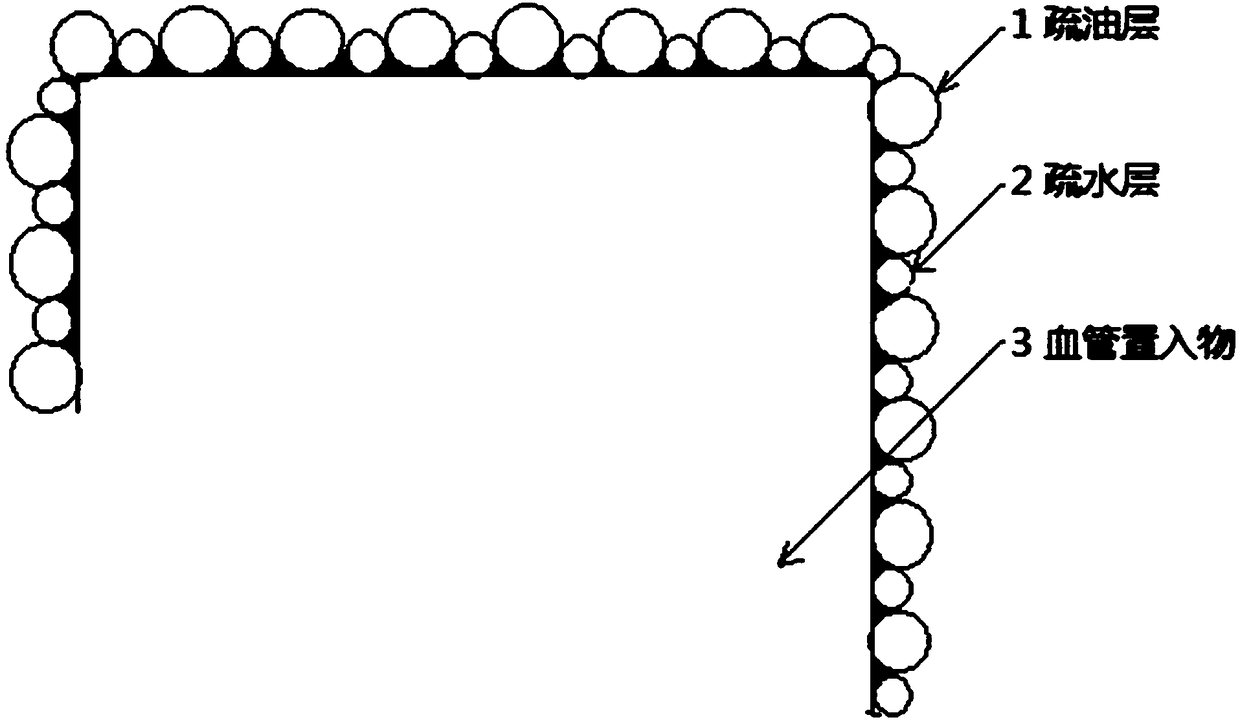

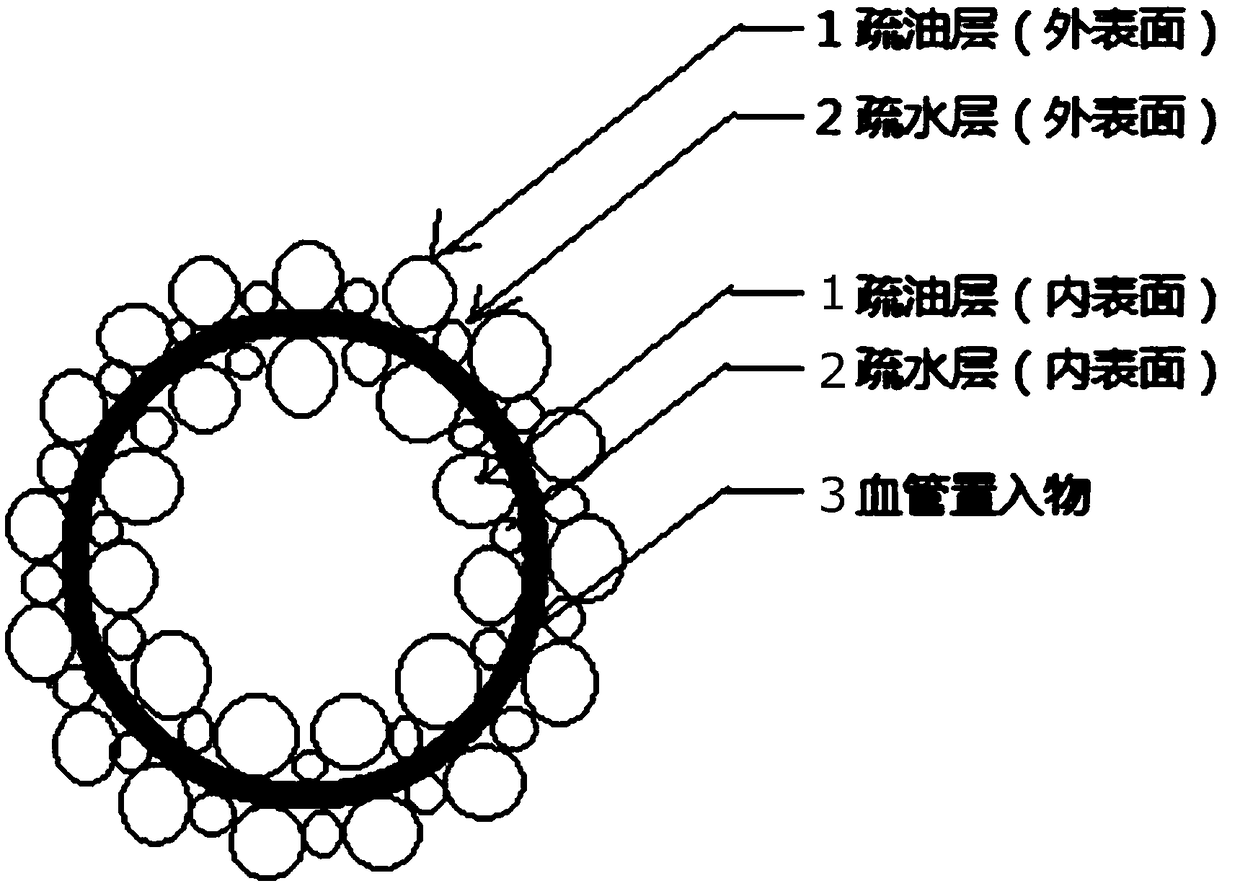

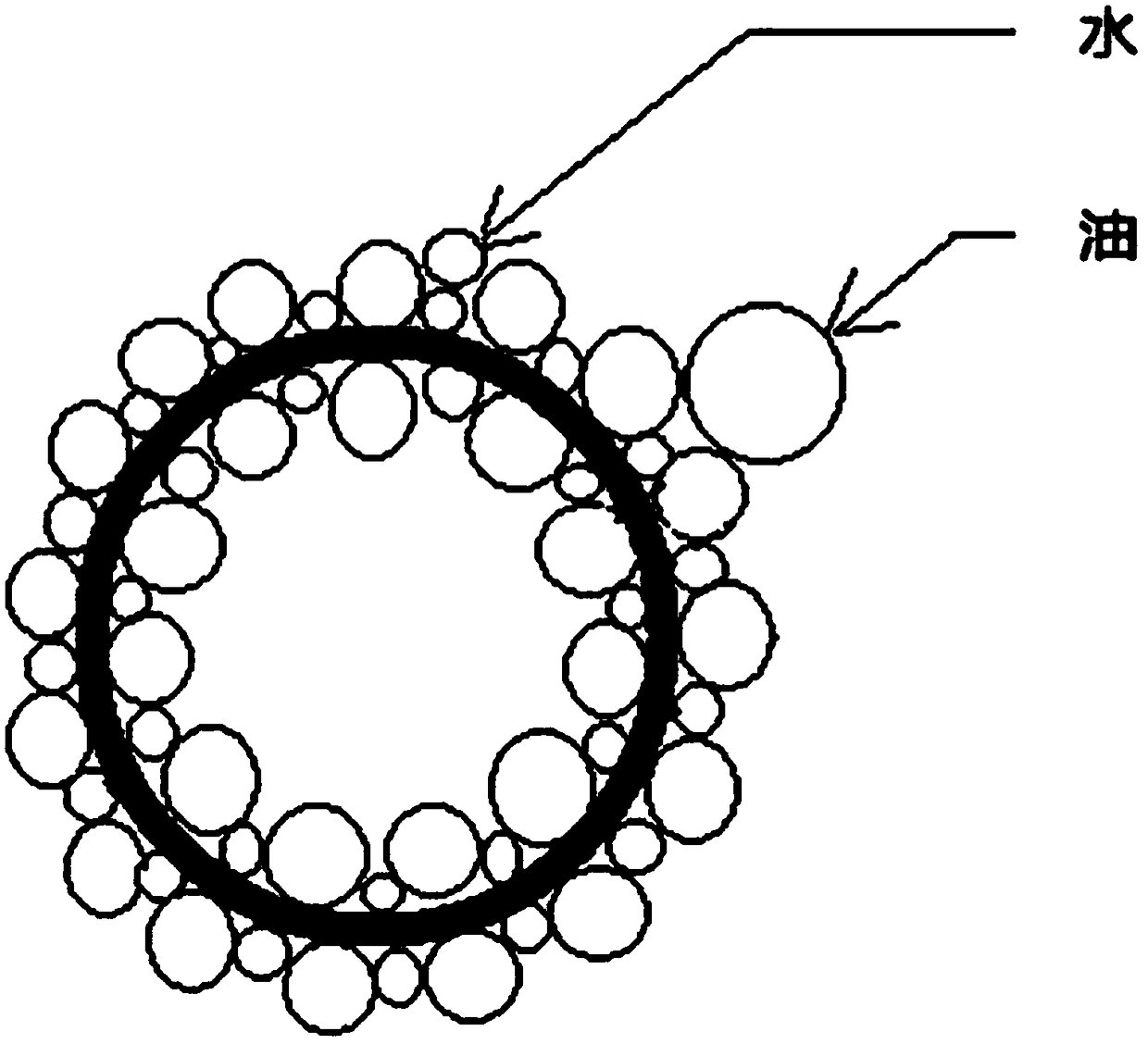

[0034] See Figure 1-Figure 3 , with figure 1 It is a partial schematic diagram of the implant surface nano-coating of the present invention, with figure 2 It is a schematic diagram of the nano-coating on the implant surface of the present invention in blood vessels, with image 3 It is a schematic diagram of the water contact angle and the hexadecane contact angle on the coating surface. The water contact angle and the hexadecane contact angle on the coating surface are all greater than 160°, and the rolling angle is less than 3°. The coating has superhydrophobicity and oleophobicity.

[0035] The present invention includes the surface of the vascular implant 3, such as the inner and outer surfaces of the deep vein catheter; the uncoated deep vein catheter is placed in the reaction chamber of the fluorocarbon polymer plasma deposition and coating equipment, and the fluorocarbon...

Embodiment 2

[0036] Example 2 Artificial blood vessel with superhydrophobic and oleophobic composite nanocoating

[0037] The present invention includes the surface of the vascular implant 3, such as the inner and outer surfaces of the artificial blood vessel; placing the uncoated artificial blood vessel in the reaction chamber of the fluorocarbon polymer plasma deposition coating equipment, using fluorocarbon as the working gas, The polymerization reaction is carried out on the surface, and a nano-coating composed of fluorocarbon polymer is formed on the inner and outer surfaces, and the thickness of the nano-coating is 400nm. The nano-coating includes an oleophobic layer 1 and a hydrophobic layer 2, and the thickness of the oleophobic layer 2 is greater than that of the hydrophobic layer 1.

Embodiment 3

[0038]Example 3 Coronary artery stent with superhydrophobic and oleophobic composite nanocoating

[0039] The present invention includes the surface of the vascular implant 3, such as the inner and outer surfaces of the coronary artery stent; the uncoated vascular stent is placed in the reaction chamber of the fluoromolybdenum polymer plasma deposition coating equipment, and the fluorocarbon is used as the working gas to form the vascular stent on the blood vessel. Polymerization is carried out on the inner and outer surfaces of the stent, and a nano-coating composed of fluorocarbon polymer is formed on the inner and outer surfaces, and the thickness of the nano-coating is 800nm. The nano-coating includes an oleophobic layer 1 and a hydrophobic layer 2, and the thickness of the oleophobic layer 2 is greater than that of the hydrophobic layer 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com