Novel stamping automatic device for single press

An automatic device and press technology, applied in the field of presses, can solve the problems of high labor intensity of operators, low accuracy of workpiece position, poor stamping quality, etc., so as to reduce labor intensity, enhance workpiece quality, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

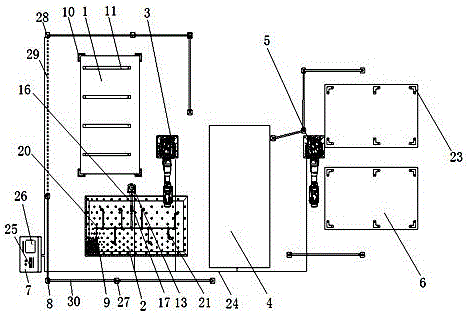

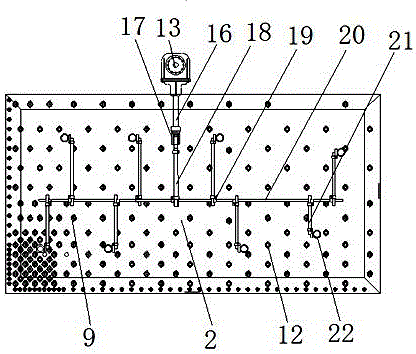

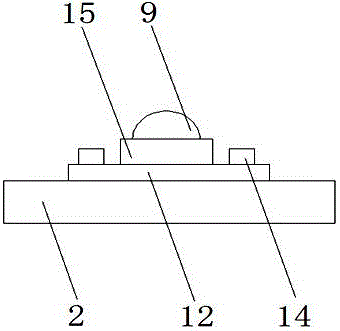

[0019] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0020] as attached Figure 1-5 As shown, a new type of stamping automation device for a single press, including a feeding table 1, a centering table 2, a feeding robot 3, a press machine 4, a feeding robot 5, a feeding car 6, an electric control cabinet 7, The column 8, the positioning seat 9 and the ball 10 are characterized in that: the feeding table 1 is arranged on the bracket 10, and a bearing rod 11 is arranged on the feeding table 1, and the centering table 2 is provided with Fixed block 13, and connecting rod 16 is arranged on fixed block 13, and described connecting rod 16 is provided with cylinder 17, and is provided with adjusting rod 18 on cylinder 17, and described adjusting rod 18 is provided with connecting block 19, and a gear lever 20 is provided on the connecting block 19, and a limit rod 21 is set on the gear lever 20 through the connecting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com