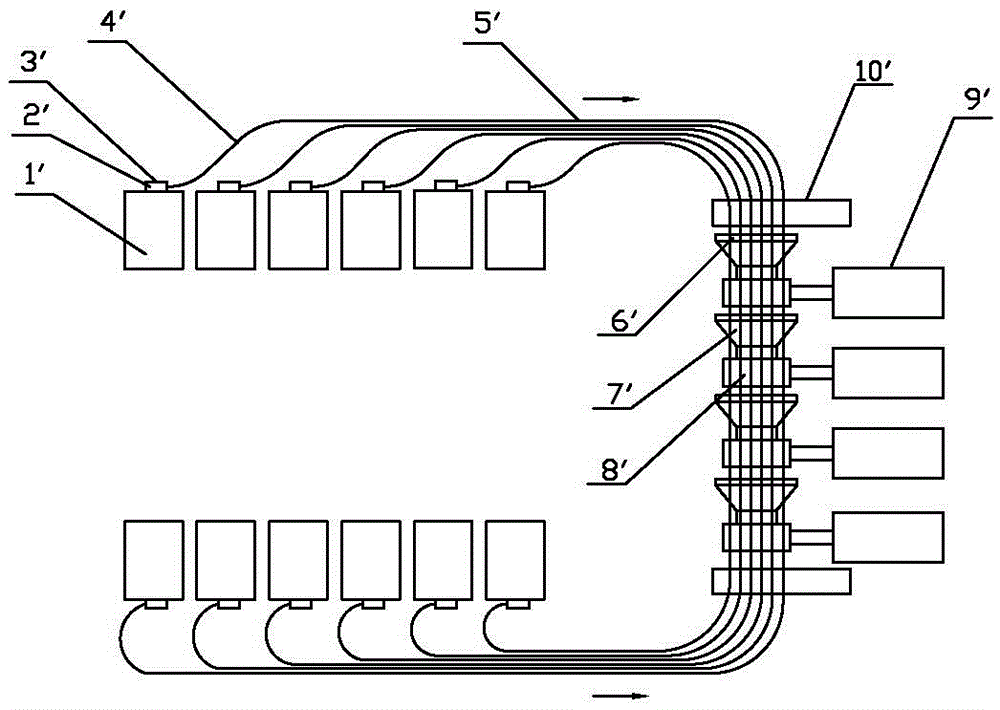

Flexible single-docking multi-brand case filling and sealing system

A multi-brand and flexible technology, applied in the directions of packaging, packaging protection, transportation and packaging, etc., can solve the problems that cigarettes cannot enter the same cigarette box, information acquisition and quality traceability can not be realized, and achieve multi-brand The effects of packaging, accurate traceability, and accurate traceability positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

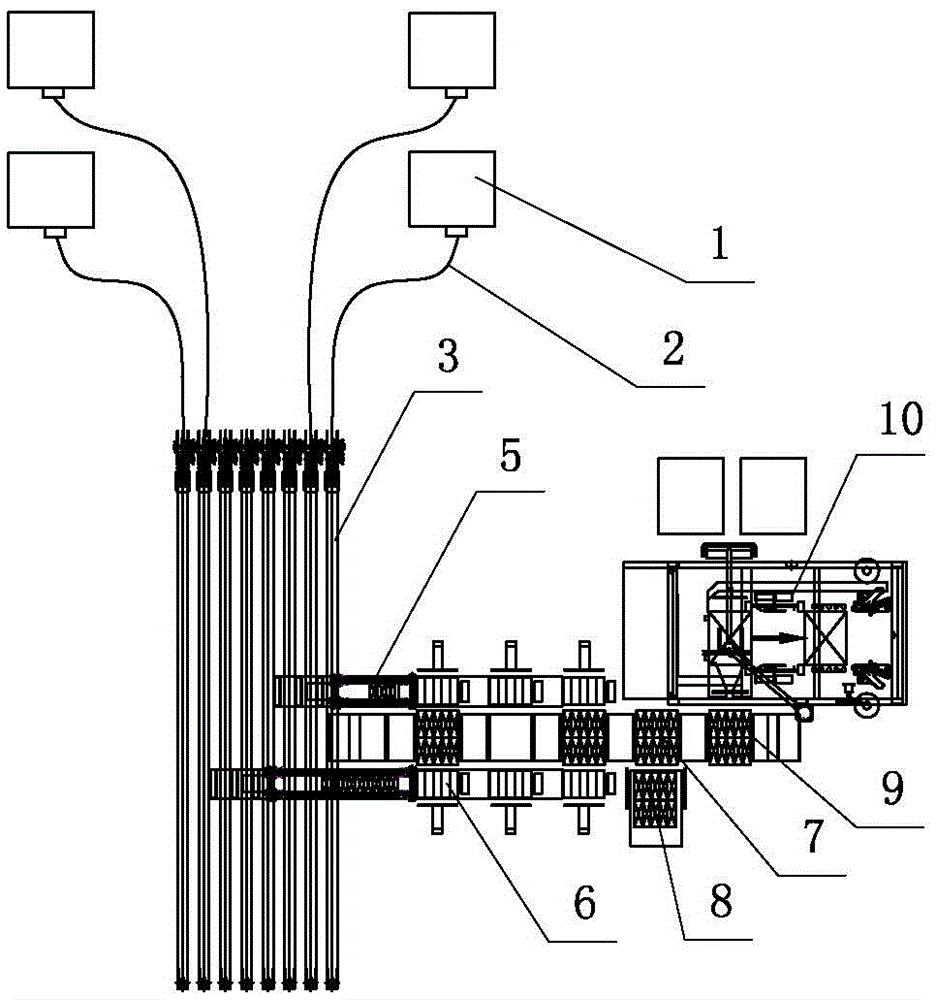

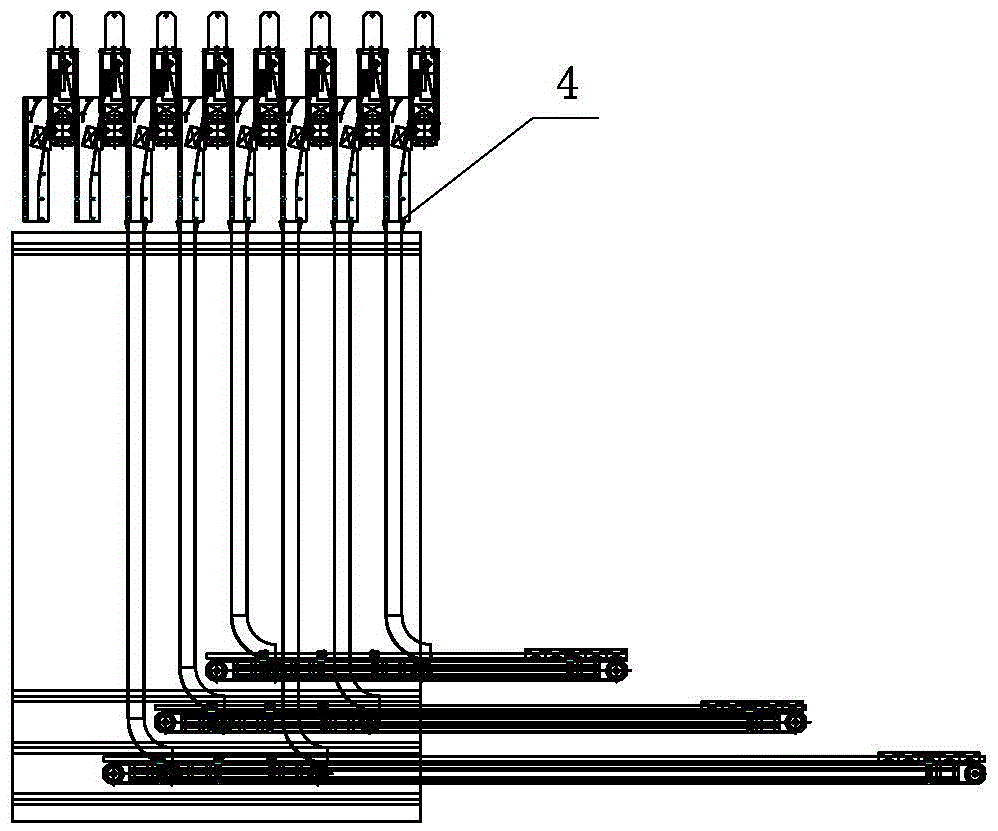

[0021] Such as figure 2 As shown, the flexible single docking multi-brand box packing and sealing system includes the wrapping unit 1, the cigarette hoist 2, the elevated chain plate conveyor 3, the buffer slideway mechanism 4, the cigarette conveying mechanism 5, which are arranged in this order. Stacking mechanism 6, cigarette stack storage and conveying mechanism 7, emergency smoke outlet mechanism 8, full stack filling station 9, box packing and sealing machine 10; wrapping unit 1, cigarette hoist 2, elevated chain conveyor 3, Buffer glideway mechanism 4, rod conveying mechanism 5, stacking mechanism 6, cigarette stack storage and conveying mechanism 7, emergency smoke outlet mechanism 8, full stack filling station 9, case packing and sealing machine 10 cooperate with each other and connect in sequence to form a work Assembly line; the emergency smoke outlet mechanism 8 is set under the cigarette stack storage and conveying mechanism 7; the emergency smoke outlet mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com