Glass loading and unloading device and control method thereof

A glass and mechanical device technology, which is applied in the field of glass loading and unloading devices, can solve the problems of limited number of stations, high labor intensity, and low production efficiency, and achieve the effects of reducing production costs, reducing labor intensity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

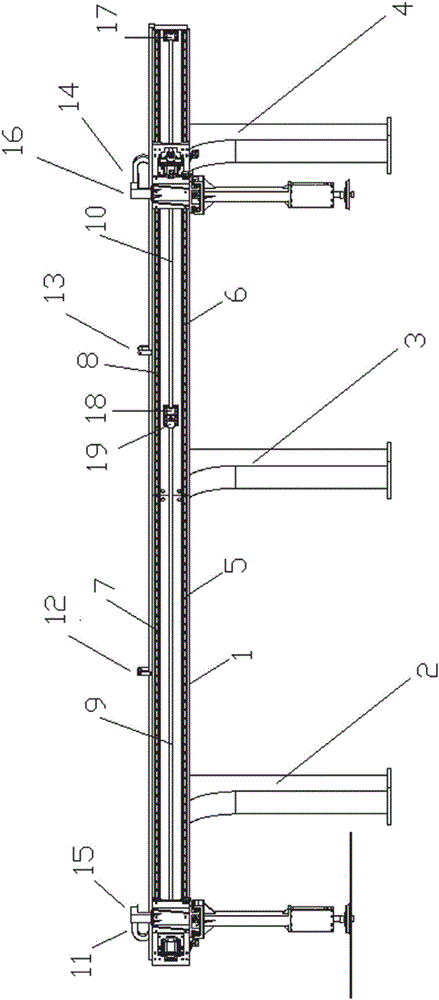

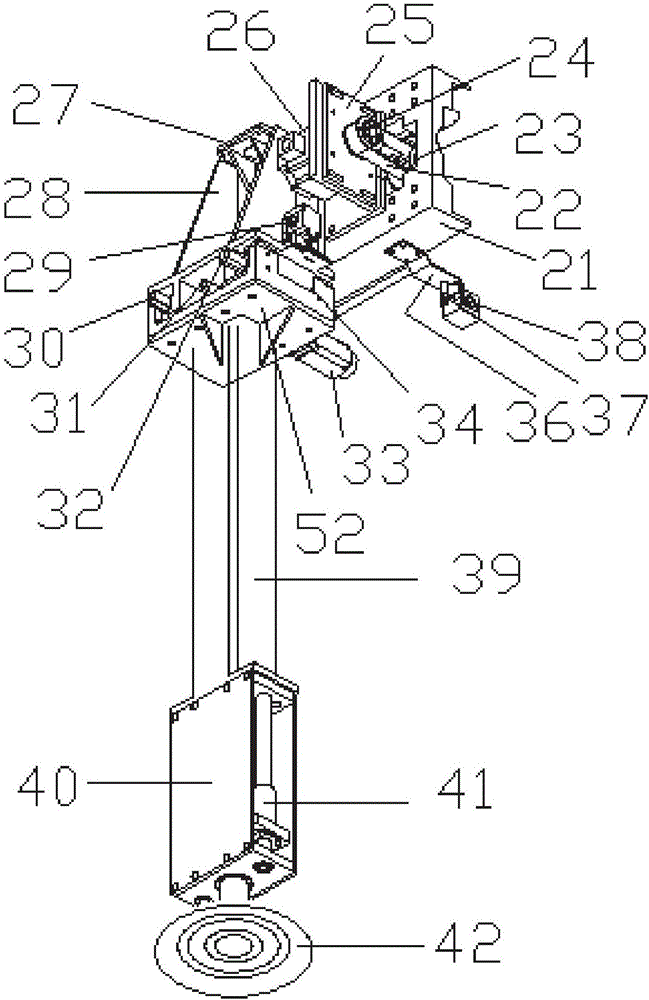

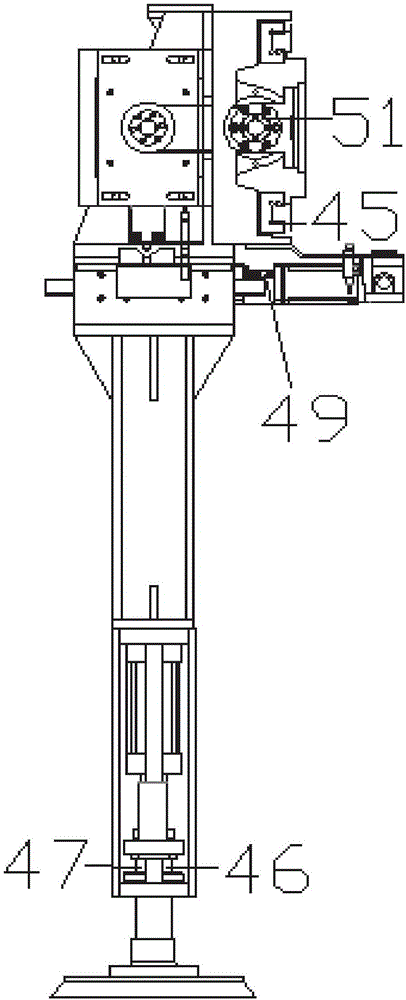

[0048] Such as figure 1 Shown: A glass loading and unloading device is mainly composed of three parts: a frame, a feeding mechanism, and a discharging mechanism. The column A2, column B3, and column C4 of the rack are provided with a beam 1; the beam 1 is provided with a linear guide rail A5, a linear guide rail B7, a linear guide rail C6, and a linear guide rail D8; the middle position of the linear guide rail A5 and the linear guide rail B7 passes through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com