Vision-based container automatic joint and hoisting system and hoisting method

An automatic docking and container technology, applied in transportation and packaging, load hanging components, program control in sequence/logic controllers, etc., can solve problems such as low efficiency and long docking hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below with reference to the accompanying drawings and examples.

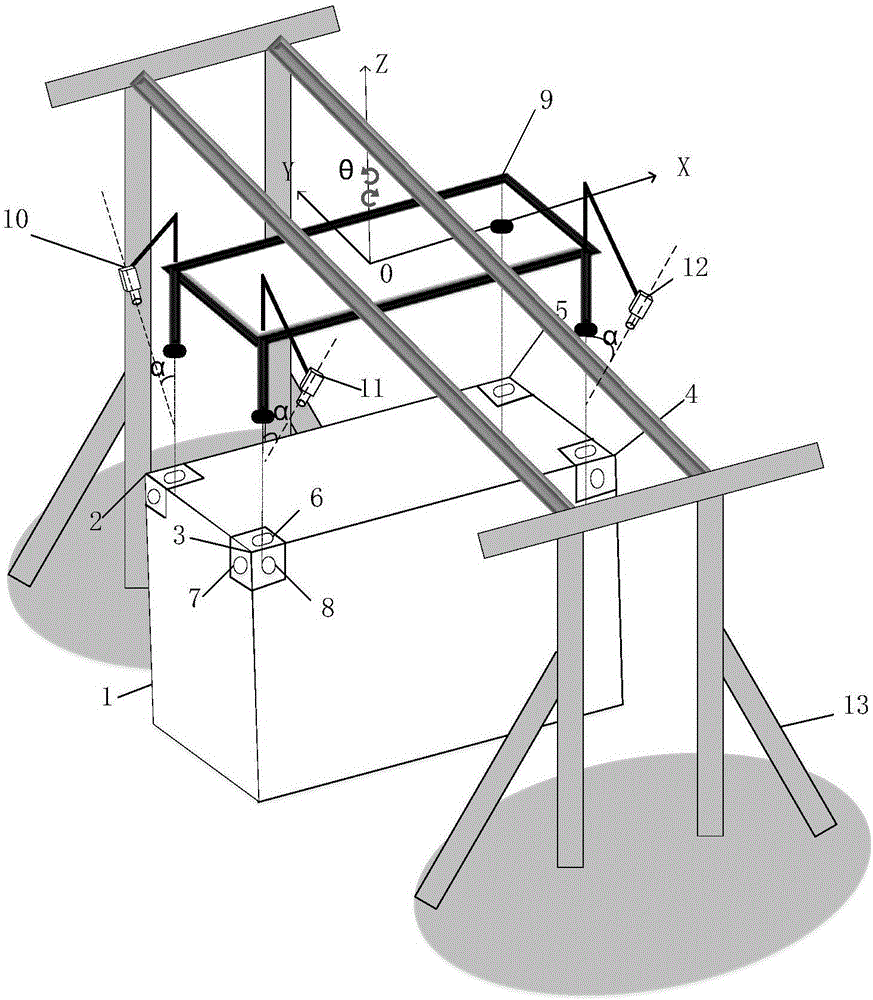

[0058] The invention provides a vision-based container automatic docking and lifting system, such as image 3 As shown, the system includes a vision system, a lifting platform 9, a control system 17 and butt corner fittings 2, 3, 4, 5 installed at the four corners of the container.

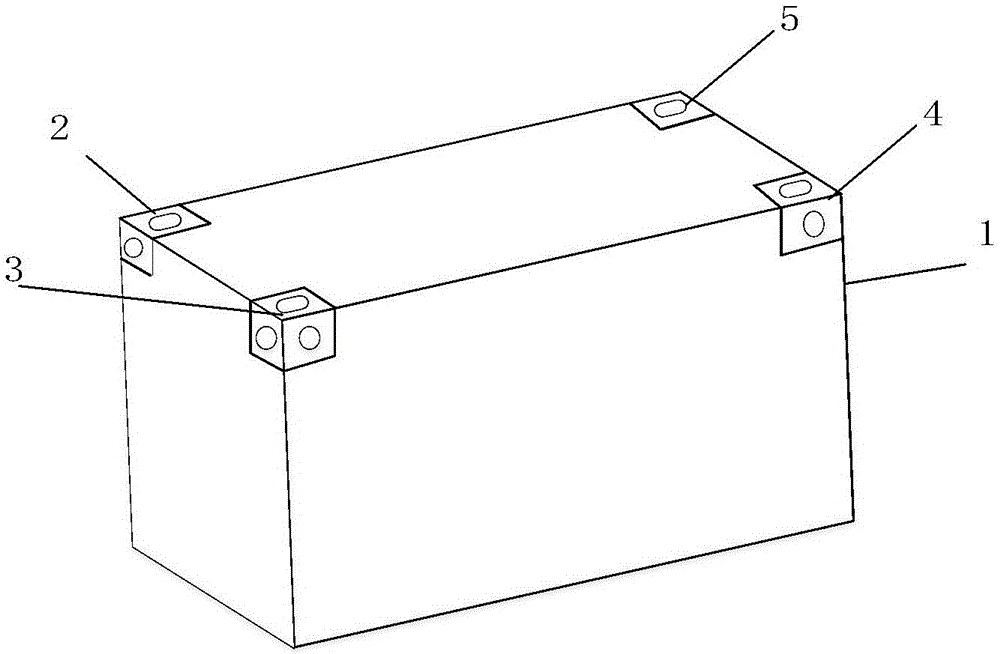

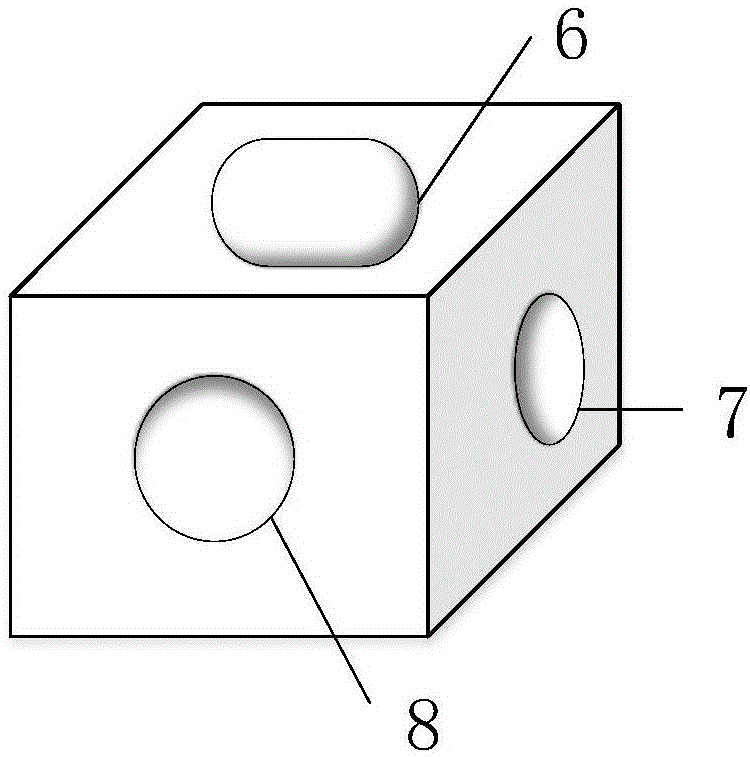

[0059] Such as figure 1 As shown, the container 1 is a cuboid structure, and the four corners of the top surface are respectively fixed with docking corner fittings 2, 3, 4, 5, which are mainly used for docking with the lifting platform 9. Such as figure 2 Shown is an enlarged schematic diagram of the butt joint corner fittings in this embodiment, butt joint holes are opened on the top surfaces of the butt joint corner fittings 2, 3, 4, 5, here are rounded rectangular holes, of course, other shapes can also be used. The docking corner pieces are provided with circular hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com