Process for making biomimetic composite functional structure by diatomite acid etching

A technology for composite functions and structures, which is applied in the field of making biomimetic composite functional structures by acid etching of diatomite, can solve the problems of lack of diatomite at room temperature, high reaction temperature, stress damage, etc., and achieves the promotion of practical effects and life expectancy. , The effect of improving process operability and good bonding state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

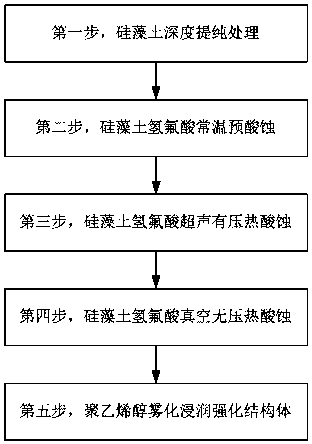

[0030] see figure 1 As shown, the present invention is a process for making a biomimetic composite functional structure by diatomite acid etching, including the following process steps.

[0031] The first step: diatomite deep purification treatment

[0032] (A) Place commercially available high-purity diatomite in a glass container, add 25ml of deionized water per 1g of diatomite, add deionized water, and ultrasonically clean for 30min under the conditions of power 150W and working frequency 40kHz, Use a filter cloth with a pore size of 5 μm for separation, and filter to obtain the first supernatant;

[0033] (B) Place the first supernatant in a glass container, add 30ml of sulfuric acid for every 1g of the first supernatant, add sulfuric acid with a mass percentage concentration of 60%, and ultrasonically clean it for 30min under the conditions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com