A spheroidizing annealing process of h13 hot work die steel

A hot-working die steel and spheroidizing annealing technology, which is applied in the field of heat treatment of die steel, can solve the problems of small carbide size, low spheroidizing annealing level, and the spheroidizing effect cannot reach the super quality level, so as to improve the lateral impact The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

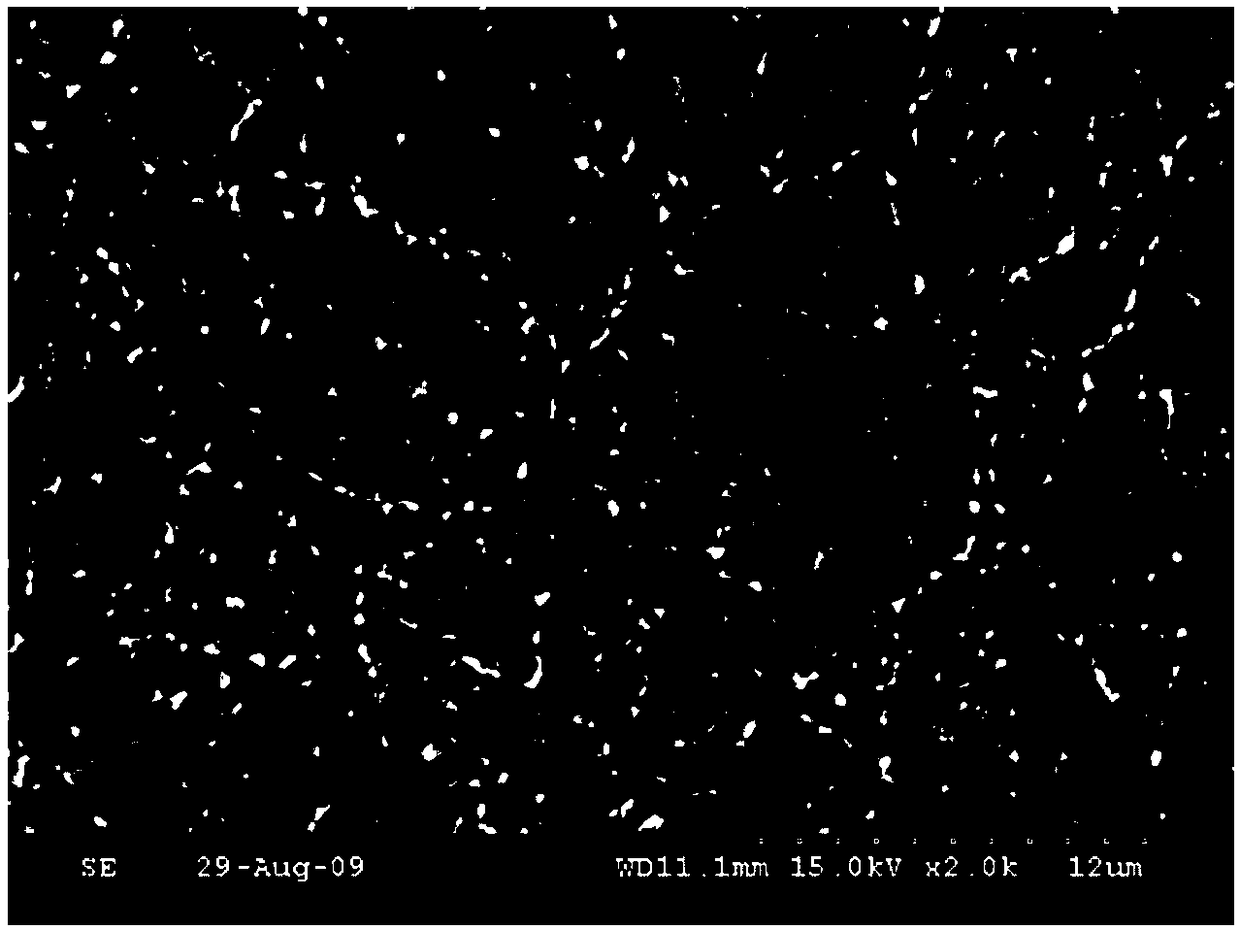

[0021] Select forged section size For round bars, the specific heat treatment process is as follows:

[0022] (1) After forging Cool the steel billet to 430°C, put it into the furnace, heat it up to 750°C at a heating rate of 70°C / h for preheating and heat preservation, hold for 1 hour, then raise the temperature to 1000°C at a heating rate of 70°C / h, and then Insulate for 3 hours, then cool the furnace to 500°C and release it in air.

[0023] (2) Heat the furnace, raise the temperature to 900°C at a heating rate of 70°C / h, keep the furnace material for 0.5h after being fully protected, and then air-cool it out of the furnace to complete the pretreatment process.

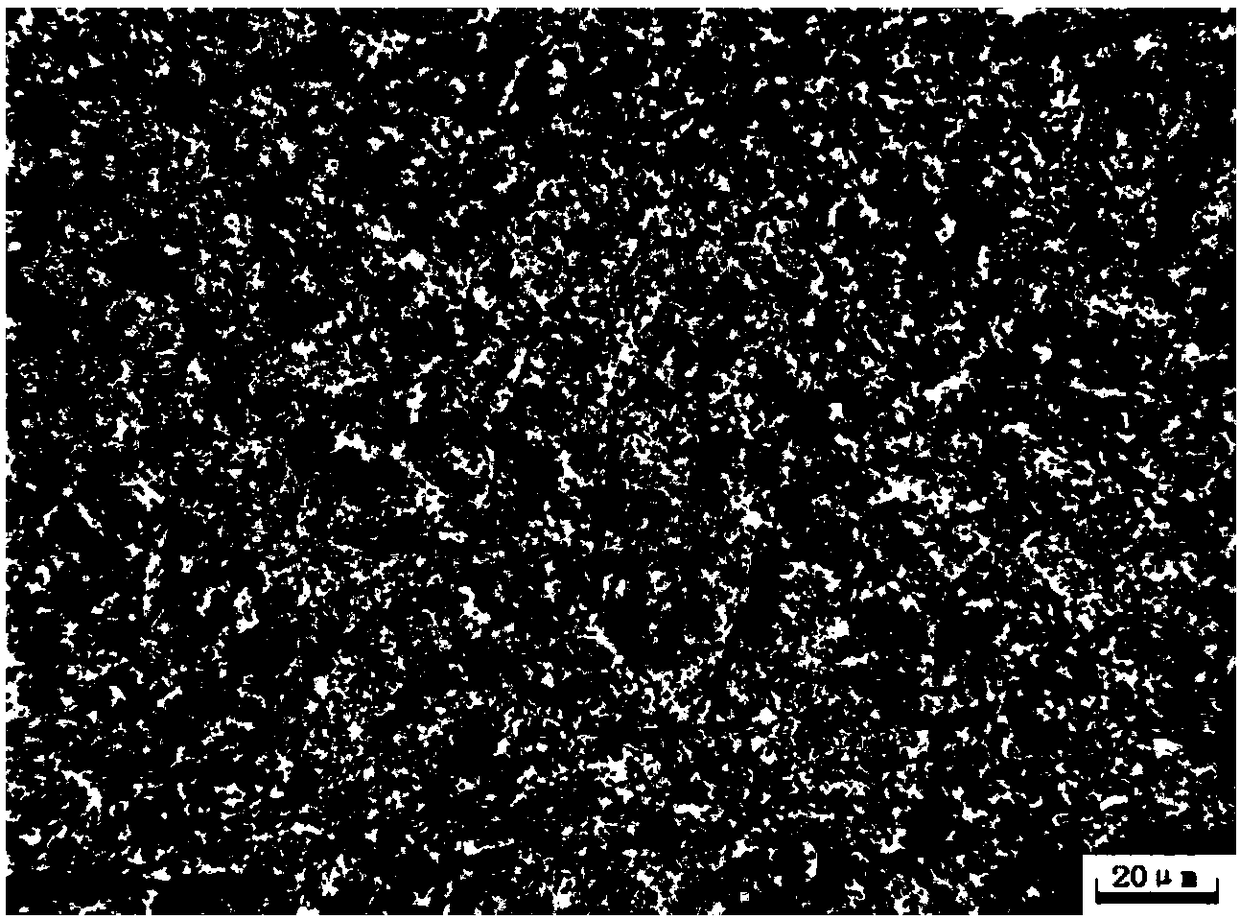

[0024] (3) Furnace at 300°C, including the forged billet (comparison sample) and pretreated billet, heat up to 880°C at a heating rate of 70°C / h, hold for 4 hours, and cool to 15°C / h at a cooling rate 760°C, after 8 hours of heat preservation, cool to 455°C at a cooling rate of 15°C / h and air-cool to complete t...

Embodiment 2

[0027] Select forged section size For round bars, the specific heat treatment process is as follows:

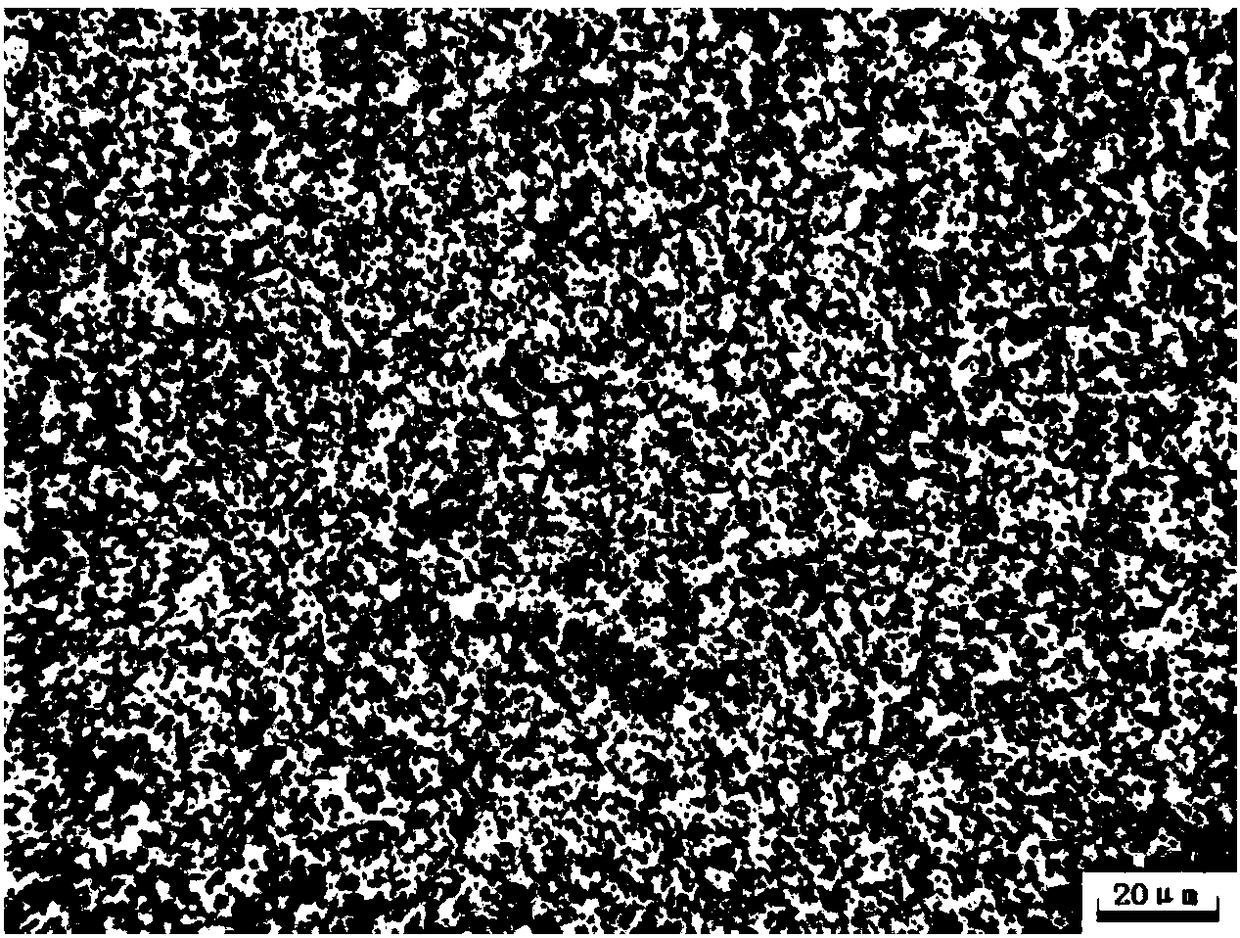

[0028] (1) After forging Cool the steel billet to 480°C, put it into the furnace, heat it up to 750°C at a heating rate of 70°C / h for preheating and heat preservation, hold for 1 hour, then raise the temperature to 980°C at a heating rate of 70°C / h, and then Keep it warm for 5 hours, then cool it to 480°C and release it in air.

[0029] (2) Thermally charge the furnace, raise the temperature to 900°C at a heating rate of 70°C / h, keep the charge for 1 hour after the furnace material is fully protected, and then air-cool it out of the furnace to complete the pretreatment process.

[0030] (3) Furnace at 370°C, including the forged billet (comparison sample) and pretreated billet, heat up to 880°C at a heating rate of 70°C / h, hold for 6 hours, and cool to 15°C / h at a cooling rate 760°C, after holding for 10 hours, cool to 500°C at a cooling rate of 20°C / h and air-cool to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com