A two-way stirring medium-pressure jet variable-diameter stirring pile drill pipe head

A two-way mixing, drill pipe head technology, applied in drill bits, sheet pile walls, earthwork drilling and other directions, can solve the problems of complex structure, inability to change the angle of shotcrete, unfavorable uniform mixing of pile foundations, etc., to achieve simple structure, grouting uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

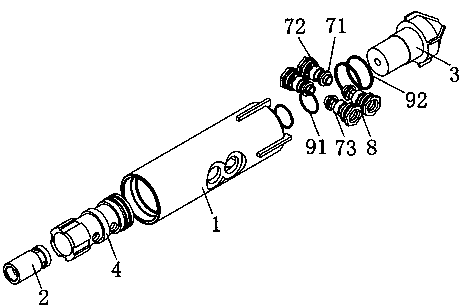

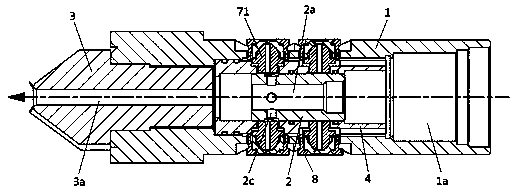

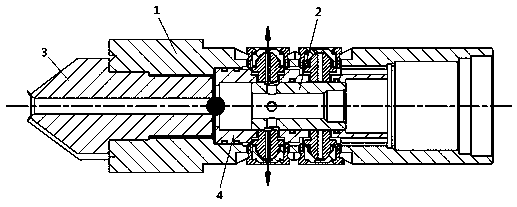

[0033] Figure 1 to Figure 17 It is a structural schematic diagram of an embodiment of the present invention.

[0034] The reference signs are: drill bit connection thread A, drill pipe connection thread B, positioning hole K, drill sleeve 1, three-step connection hole 1a, inner sleeve assembly hole 1b, drill step assembly hole 1c, positioning ring platform 1d, clip Spring groove 1e, piston 2, grouting channel 2a, grouting channel 2b, radial communication hole 2c, drill bit 3, grouting channel 3a, inner sleeve 4, sliding chamber 4a, limiting annular platform 4b, first sealing groove 4c, second sealing groove 4d, spline groove 4e, annular boss 4f, lower nozzle installation hole 5, upper nozzle installation hole 6, internal thread 6a, ball joint 71, external thread 71a, flow channel 71b, spherical body 71c, 90 Degree joint 72, 45 degree joint 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com