Spliced main keel for buildings

A main keel and plug-in technology, applied in the field of main keel, can solve problems such as complex operation, low construction efficiency, and large fire hazards, and achieve the effects of simple overall structure, improved construction efficiency, and meeting strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

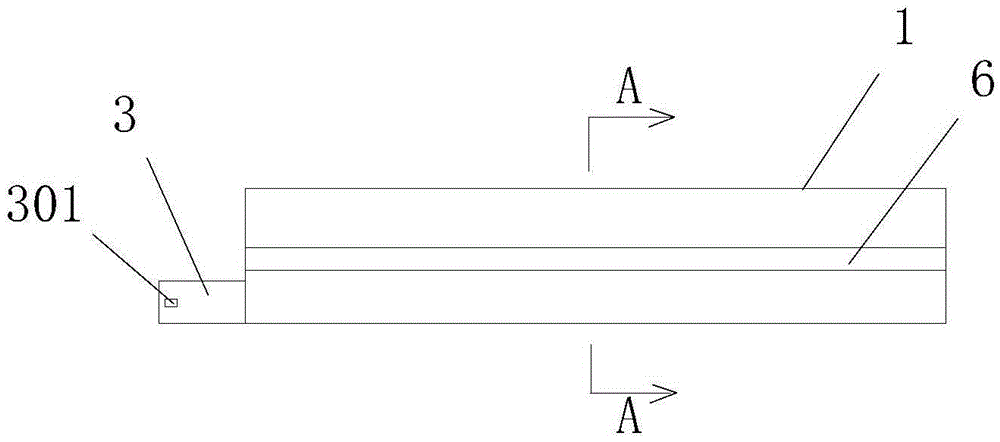

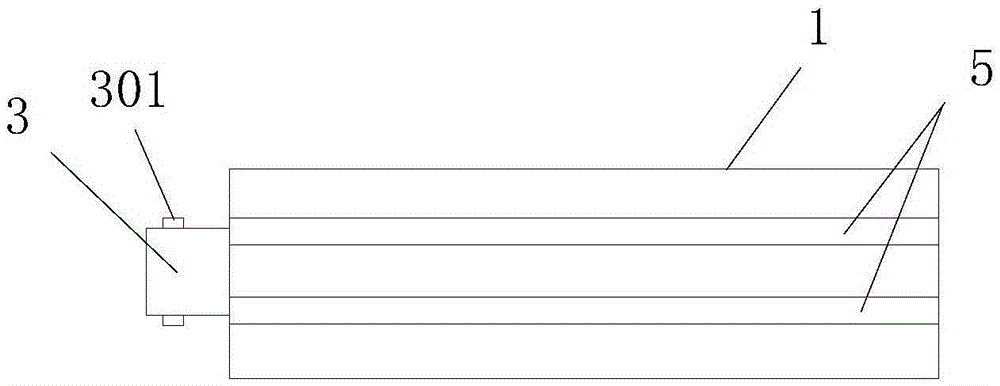

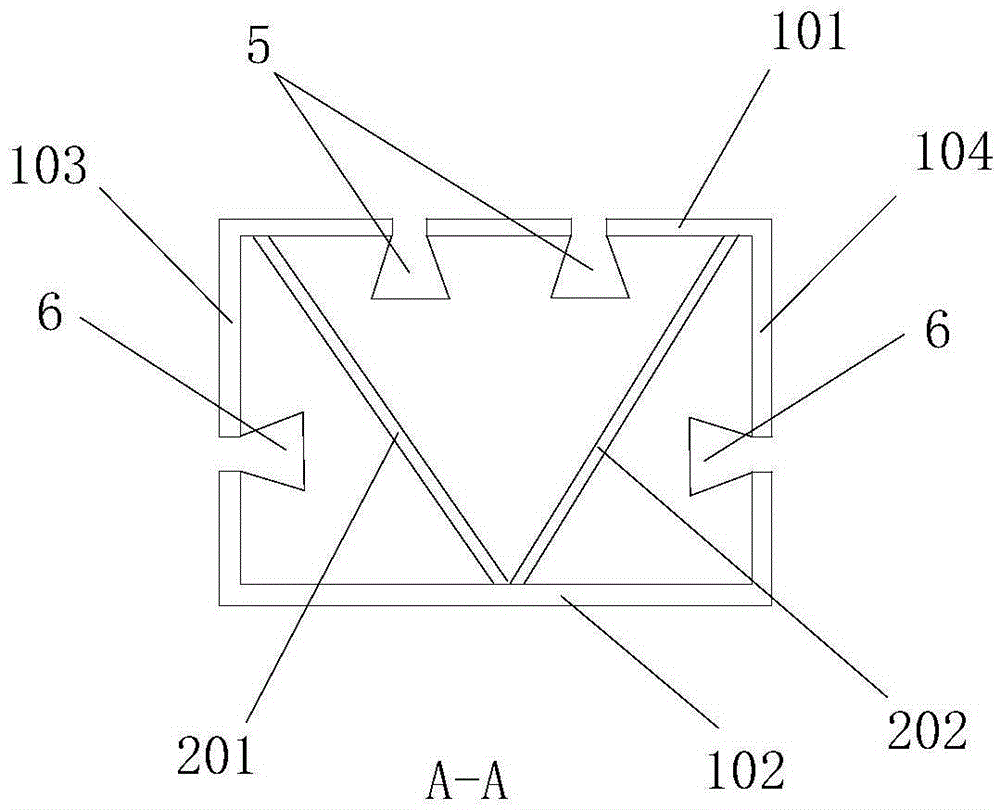

[0020] Such as Figure 1-5 As shown, the plug-in main keel for construction of the present invention includes a main keel base 1, and the main keel base is composed of an upper top plate 101, a lower bottom plate 102, a left side plate 103, a right side plate 104, a front end plate 105 and a rear end plate 106 forms a hollow rectangular parallelepiped structure, and two inclined reinforcing ribs 201 and 202 are arranged symmetrically inside the main keel base 1, and one side of the reinforcing ribs 201 and 202 is respectively connected to the upper roof 101 , the other sides of the rib plates 201 and 202 are respectively connected to the lower bottom plate 102, and the two rib plates 201 and 202 form a “V”-shaped structure.

[0021] Two first installation grooves 5 extending along the length direction of the main keel base 1 are provided on the upper top plate 101 , and the cross-section of the first installation grooves 5 is a wedge-shaped structure. On the left side plate 1...

Embodiment 2

[0025] Such as figure 1 As shown, the structure of the plug-in main keel for construction in this embodiment is basically the same as that of Embodiment 1, except that the cross-section of the first installation groove 5 is Shaped structure, the cross-section of the second installation groove 6 is shape structure, such as Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com