A motor slot wedge clamp

A motor slot wedge and fixture technology, which is used in clamping, manufacturing tools, metal processing mechanical parts, etc., can solve problems such as the danger of the unit affecting the overall efficiency of the motor, the impact of rotor dynamic balance, and low assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

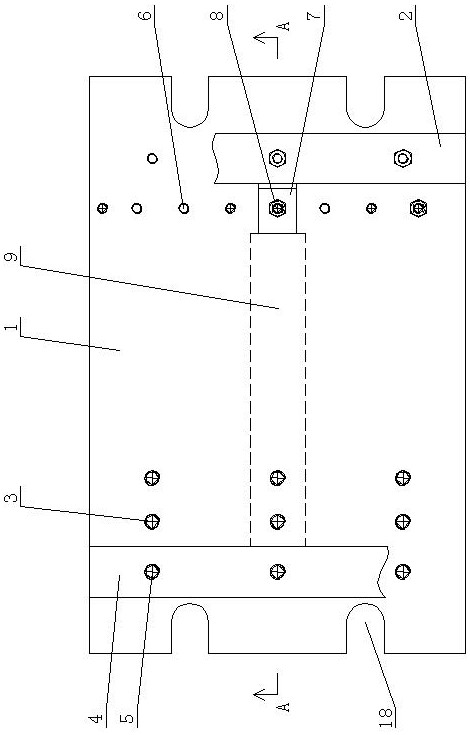

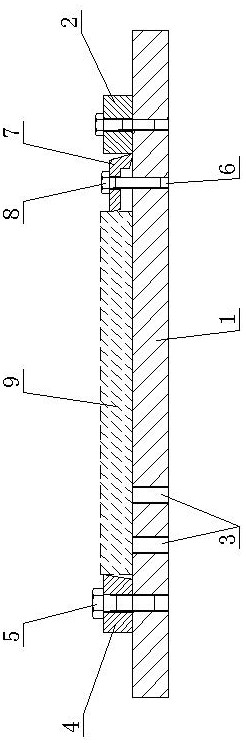

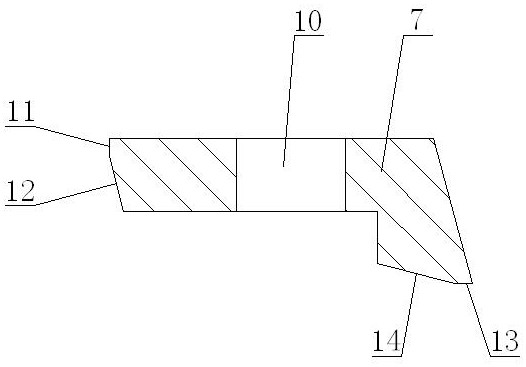

[0027] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0028] Such as Figure 1 to Figure 6 As shown, the present invention includes a tire plate 1, a fixed baffle 2 is provided on one side of the upper surface of the tire plate 1, the fixed baffle 2 is arranged along the width direction of the tire plate 1, the fixed baffle 2 is connected with the tire plate 1 through bolts, and the tire plate 1 The other side of the upper surface is provided with three rows of bolt hole groups along its length direction, and each row of bolt hole groups includes three first floor plate bolt holes 3 arranged at intervals along the width direction of the floor plate. The upper surface of the tire plate 1 is provided with an adjustable baffle plate 4, and the adjustable baffle plate 4 is provided with an adjustable baffle plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com